belt drive

A belt drive, belt technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of difficult integration of structural space, consumption, etc., and achieve the effect of increasing the wrap angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

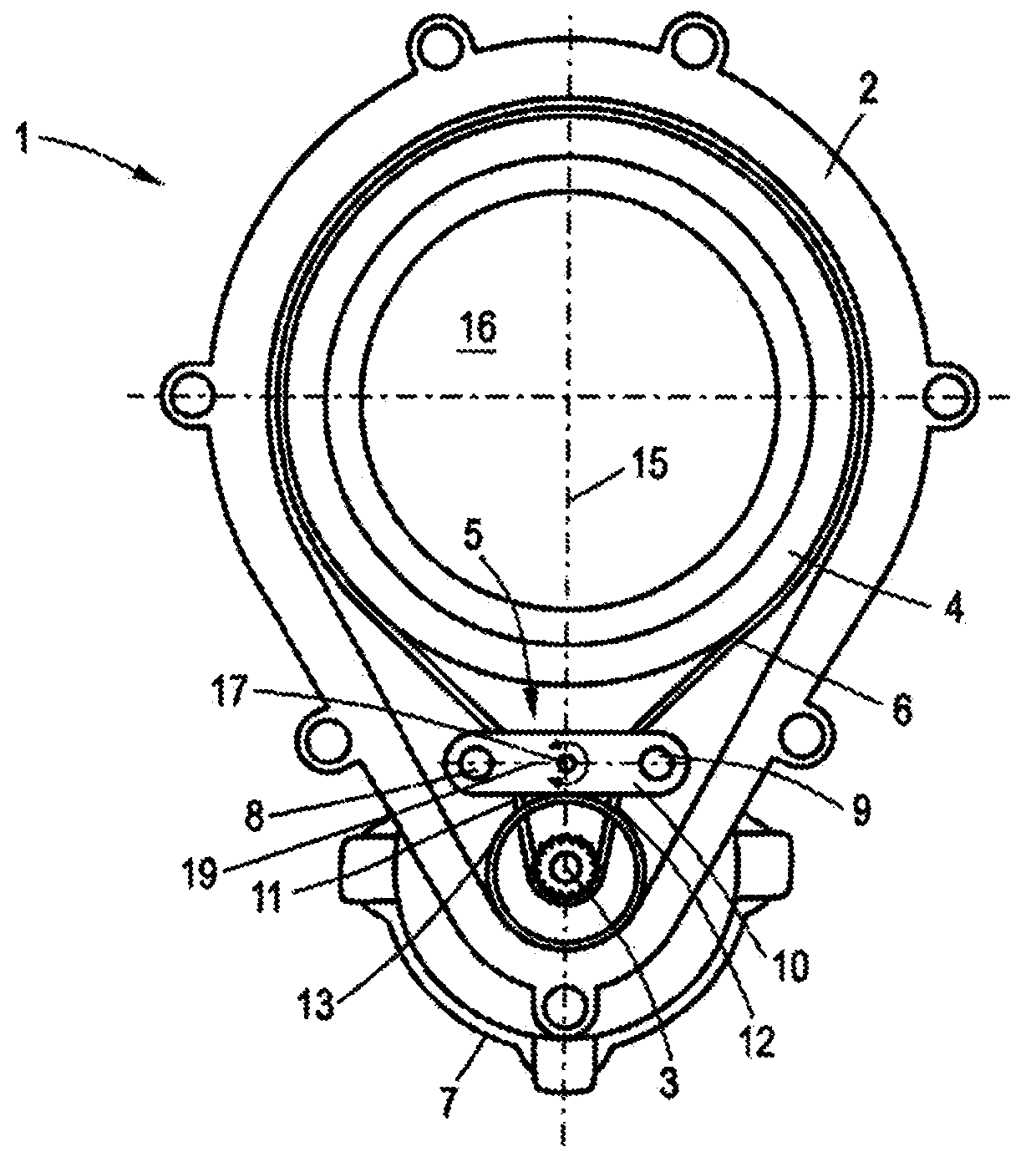

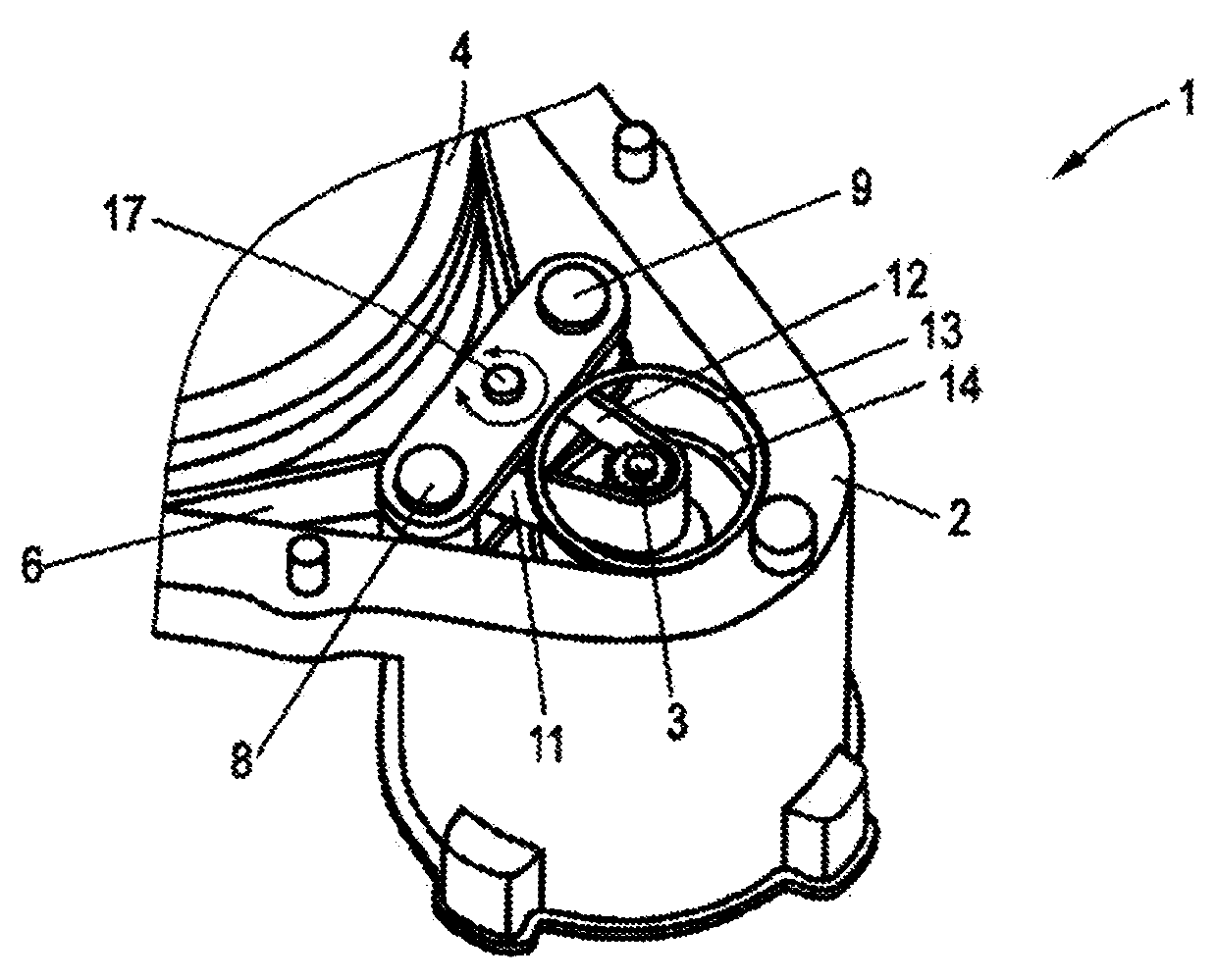

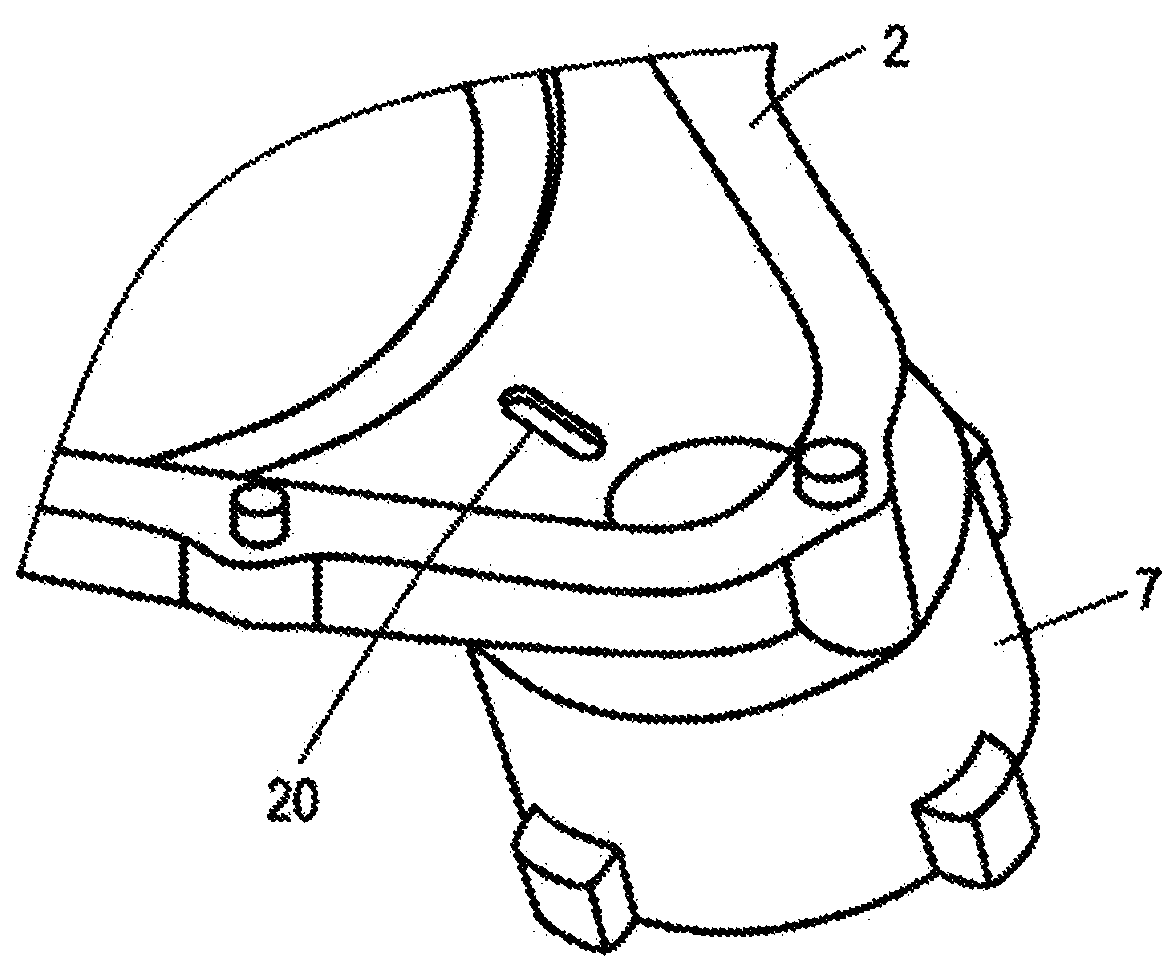

[0025] figure 1 Shows a top view of a belt drive 1 for driving an object, which is mounted in a rotatable manner, comprising: a basic body 2 and two pulleys 3, 4, means for generating a pretension 5 and a continuously looping belt 6 around pulleys 3, 4, wherein the first pulley 3 can be connected to a drive 7 and the second pulley 4 can be connected to an object, or the first pulley 3 is connected to a drive 7 and the second pulley 4 is connected to the object. Objects are not drawn for clarity reasons.

[0026]The mechanism 5 comprises in this embodiment two rollers 8 , 9 arranged on opposite sides of the rod 10 , and a rod 10 mounted in a pivotable and displaceable manner on the basic body 2 , and the rollers contact the return sections 11, 12 of the belt 6 respectively. Two spring elements are arranged between the mechanism 5 and the basic body 2 . The two spring elements 13 , 14 are designed as ring springs. Said spring element supports the rod 10 and thus the mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com