Variable firework battery

A technology of pyrotechnics and fuses, applied in the field of pyrotechnic groups, which can solve the problems of large expansion components, increased transportation costs, explosion hazards, and increased packaging size of pyrotechnic groups, and achieves the goals of reducing packaging size, increasing support strength, and improving stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

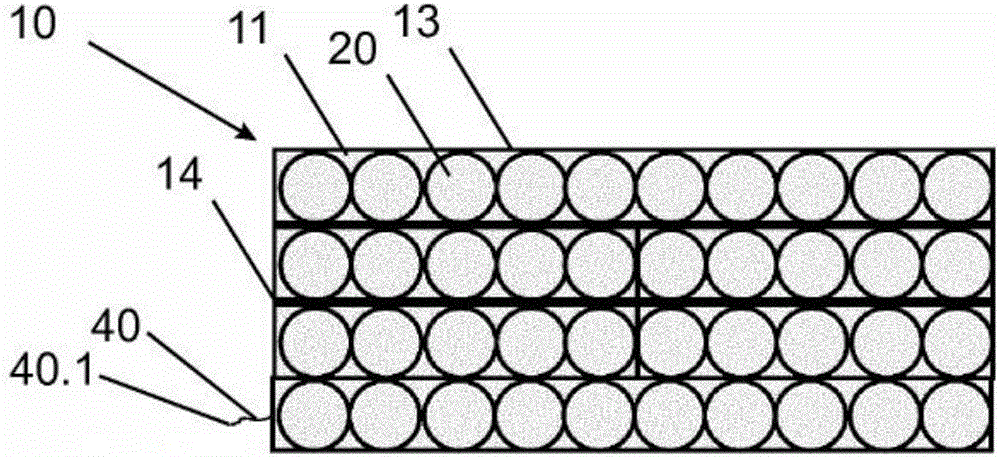

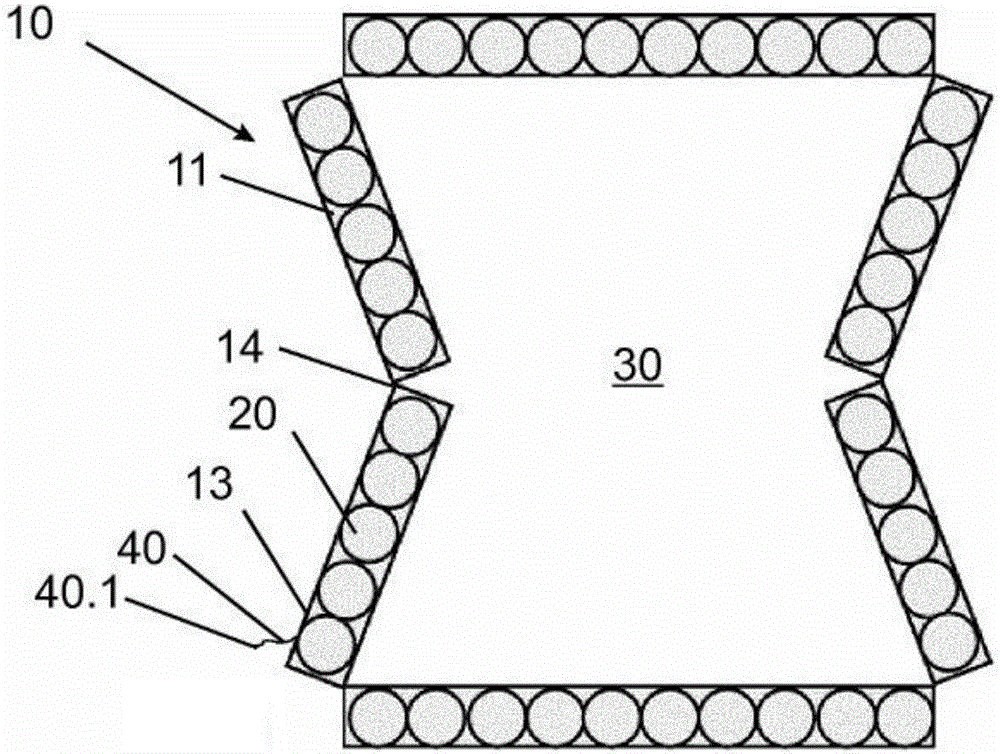

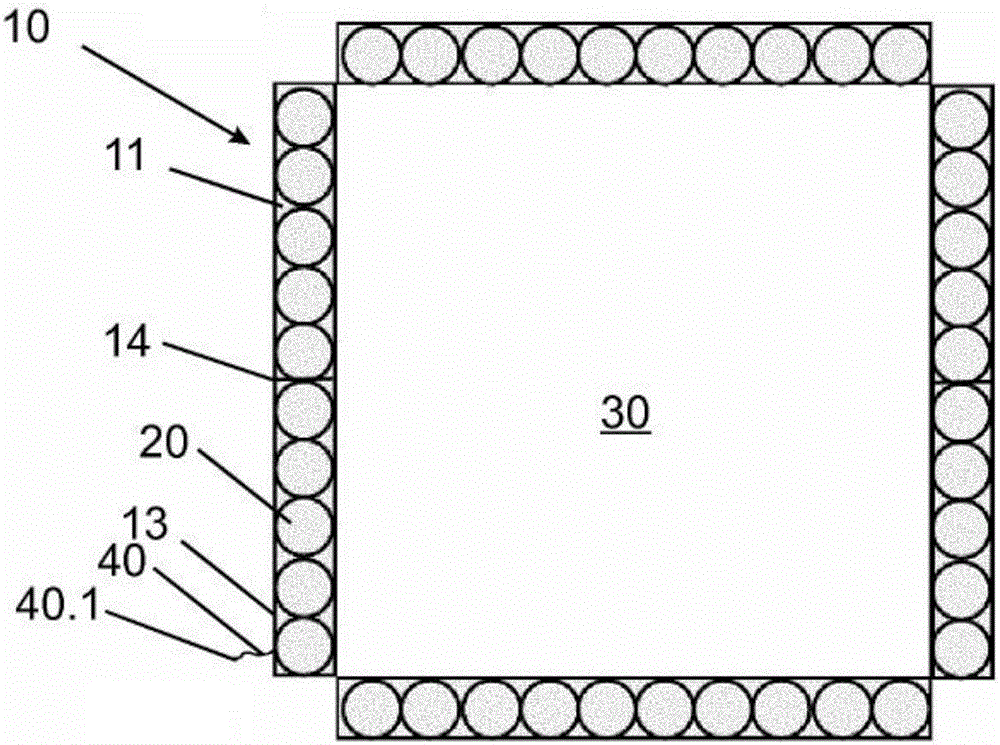

[0041] exist figure 1 A first embodiment of a pyrotechnic battery 10 according to the invention is schematically shown in the transport state, which here has, by way of example, six receptacles 11 . Each receptacle 11 is equipped with a plurality of pyrotechnic units 20 which are arranged in a single row in the receptacle 11 . Each receptacle 11 has a frame 13 and two joints 14 in each case. In the transport state shown, the receptacles 11 are arranged next to each other, so that there is no gap between the individual receptacles 11 , so that the developed support surface 30 and the package size of the pyrotechnic group 10 are as small as possible. exist figure 1 The pyrotechnic group 10 shown in has a rectangular shape, with the longitudinal sides outwardly having two receptacles 11 which are designed to be twice as long as the inner receptacles 11 . An arrangement of two longer receiving parts 11 is thus formed on the two longitudinal sides, between which four half-length...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com