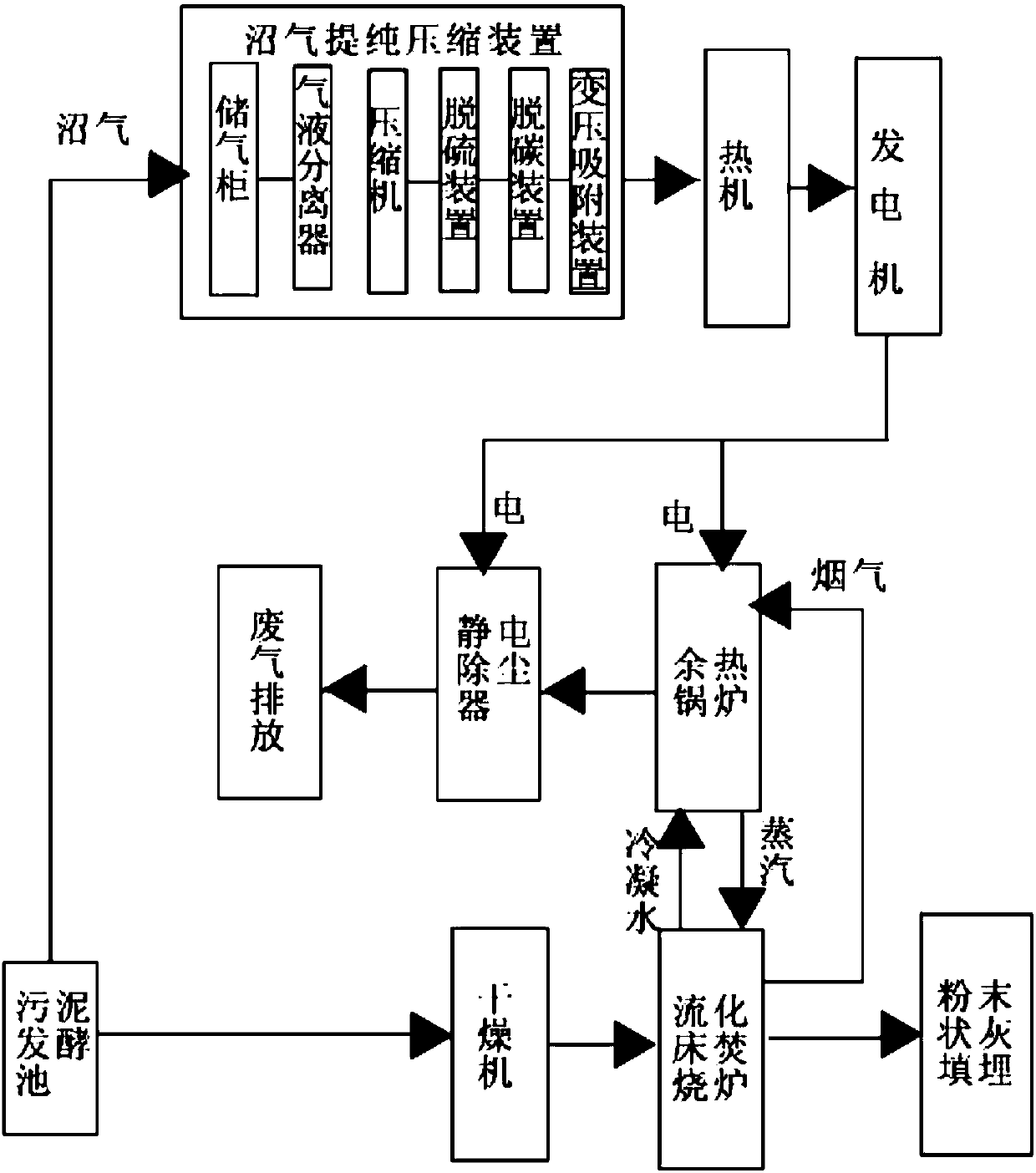

Sludge power generation and incineration treatment system

A treatment system and sludge power generation technology, applied in biomass post-processing, incinerators, combustion methods, etc., can solve the problems of affecting air quality, difficult to catch fire, occupying space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A sludge power generation incineration treatment system, which includes a sludge fermentation tank, a biogas purification and compression device, a heat engine, a generator, a dryer, an incinerator, and a waste heat boiler. The sludge fermentation tank includes a fermentation tank sludge inlet, a fermentation tank The sludge outlet and the biogas outlet of the fermentation tank. The biogas purification and compression device includes a gas storage cabinet, a gas-liquid separator, a compressor, a desulfurization device, a decarbonization device and a pressure swing adsorption device connected to each other in sequence. The dryer is equipped with Dryer sludge inlet, dryer sludge outlet, steam inlet and condensed water outlet, the incinerator includes incinerator sludge inlet, air inlet, slagging outlet and incinerator smoke outlet. The waste heat boiler is provided with a water inlet, a steam outlet, a waste heat flue gas inlet and a boiler exhaust port;

[0016] The slud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com