An all-in-one hand washing and drying machine

An all-in-one, hand-drying technology, applied in sanitary equipment, applications, household appliances, etc., can solve the problems of poor brushing effect and unsatisfactory use effect, achieve high brushing efficiency, easy maintenance or replacement of parts, and simple moving parts. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

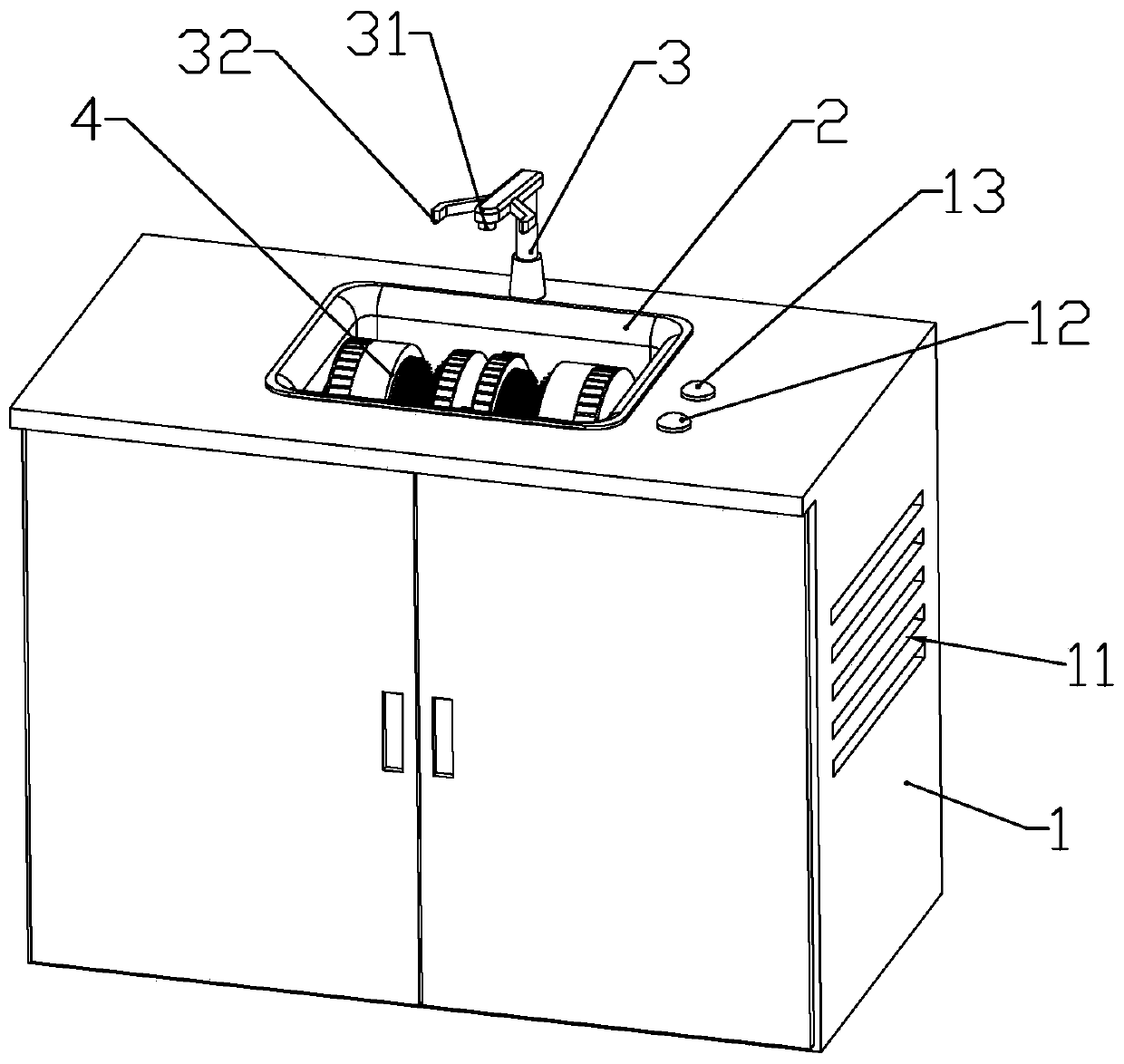

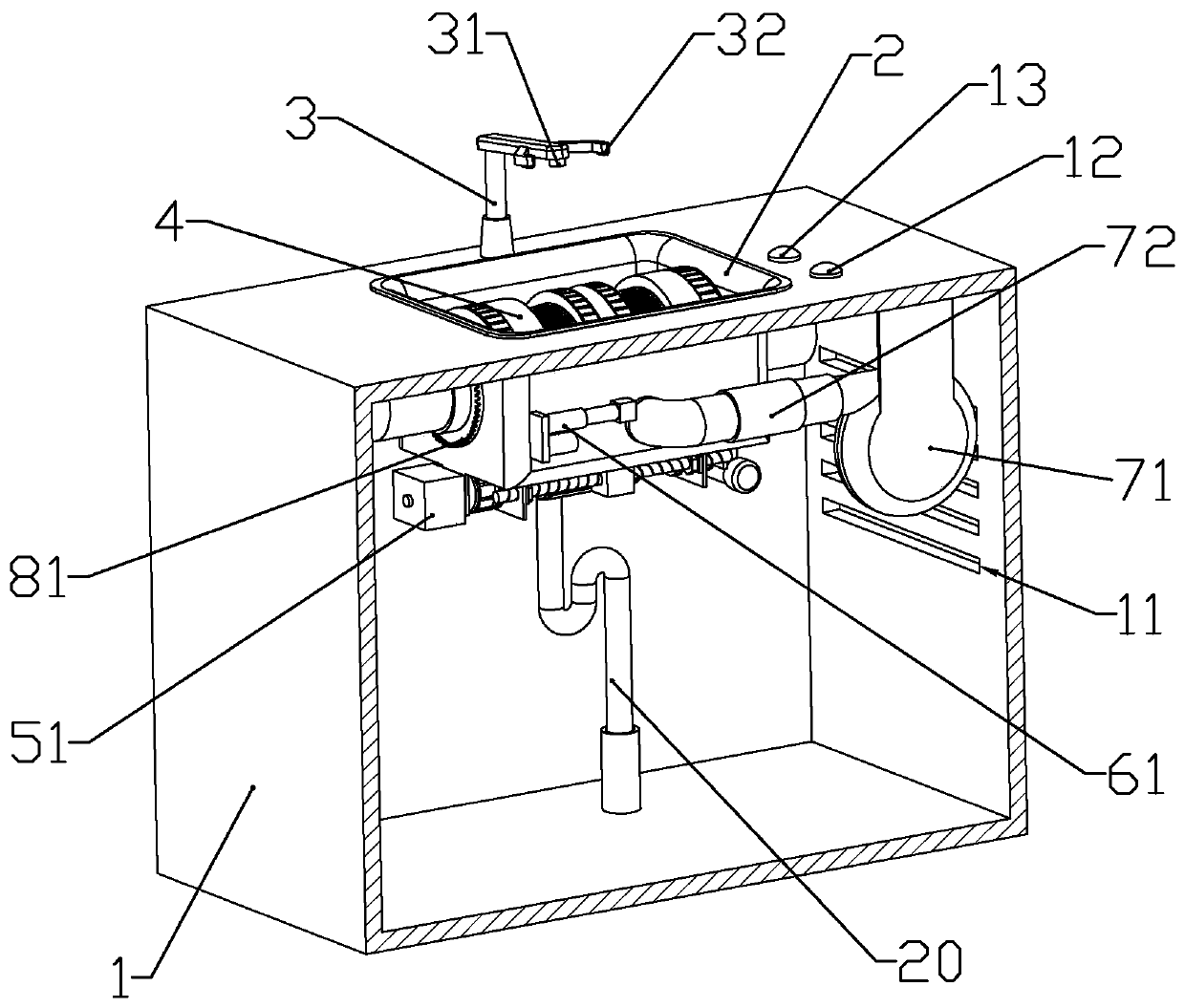

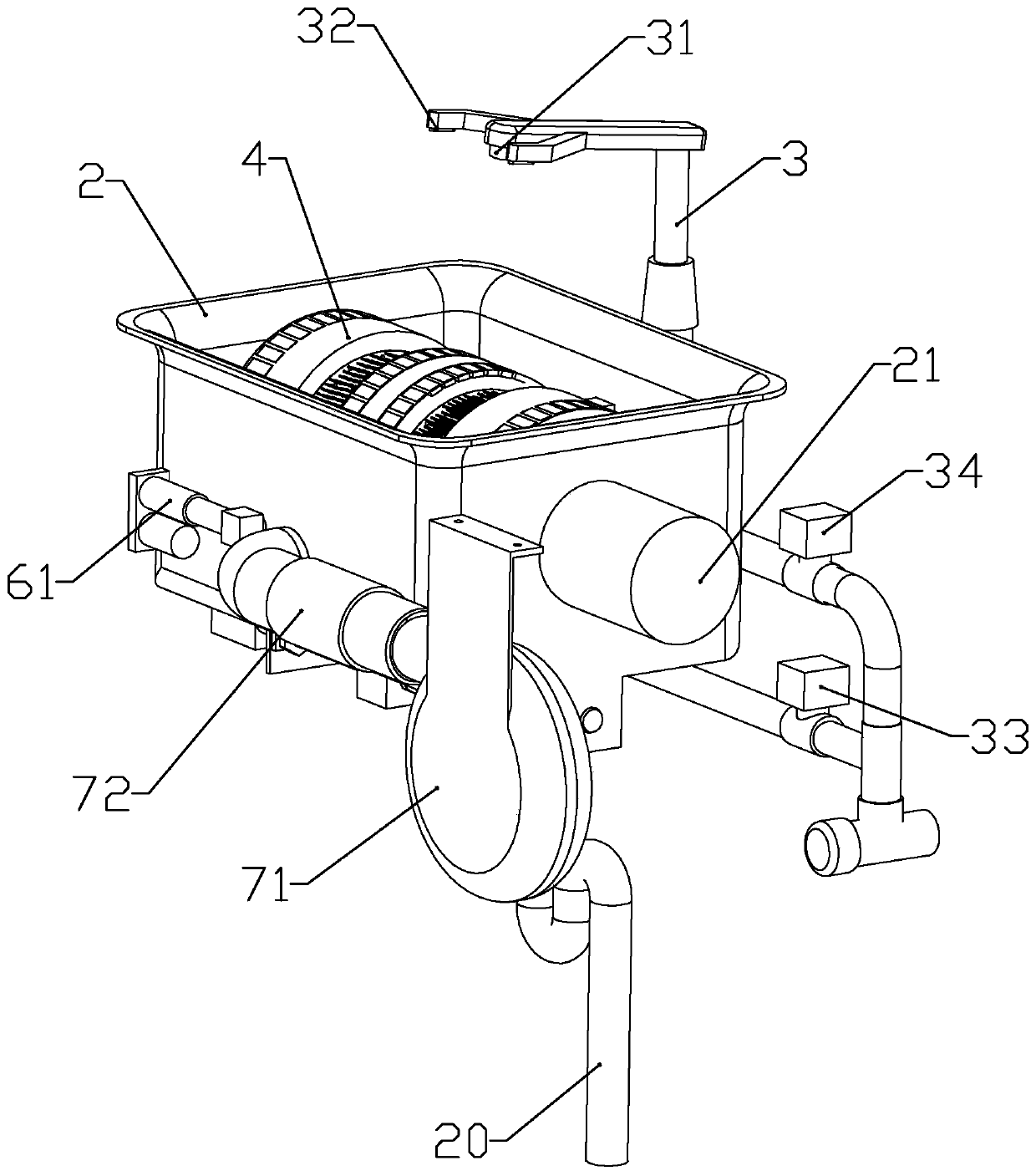

[0059] combine Figure 1 to Figure 11 As shown, this embodiment is an all-in-one hand washing and drying machine, including a cabinet body 1, a basin body 2 of non-ferromagnetic material installed on the cabinet body, installed on the upper rear side of the cabinet body and the water outlet is located above the basin body The faucet 3 in the middle position, and the scrubbing mechanism 4 installed in the basin body.

[0060] The inner bottom of the basin is connected with a drainage pipe 20, and the lower end of the drainage pipe leads to the sewer.

[0061] The scrubbing mechanism includes two first brushes 41 respectively installed on both sides of the basin, and a second brush 42 installed in the middle of the basin.

[0062] The two side walls of the basin body are symmetrically formed with circular groove-shaped lateral brush holders 21 arranged horizontally, and the two first brushes are horizontally and rotatably inserted into the lateral brush holders on both sides. ...

Embodiment 2

[0094] combine Figure 1 to Figure 14 As shown, this embodiment makes the following improvements on the basis of Embodiment 1: an arc-shaped cover 8 is rotatably connected between the rotating sockets of the two first brushes on both sides of the basin, and the arc-shaped The cover has an arc-shaped retaining wall with a central angle of 150-200 degrees and two side plates integrally connected on both sides of the arc-shaped retaining wall. The connecting ring 801; the side plate of the arc cover is connected with the first magnet 84; the outside of the basin and the lateral brush seat on the same side as the first magnet are rotated and installed with a transmission gear 81, and the transmission gear is connected with The first magnet attracts the second magnet 82 tightly through the force of the magnetic field; the outer wall of the basin is equipped with a cover drive motor a83, and the output shaft of the cover drive motor a is connected with a drive gear connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com