Cleaning device for transmission shaft system

A technology for cleaning devices and transmission shafts, which can be applied to cleaning methods using tools, cleaning methods and utensils, chemical instruments and methods, etc., and can solve problems such as delays in construction periods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] An embodiment of the present invention provides a cleaning device for a transmission shaft system. The transmission shaft system is a common power transmission mechanism in construction machinery, and mainly includes a support structure and a transmission shaft. The transmission shaft is rotatably mounted on the support structure, thereby The transmission shaft can be effectively supported by the support structure.

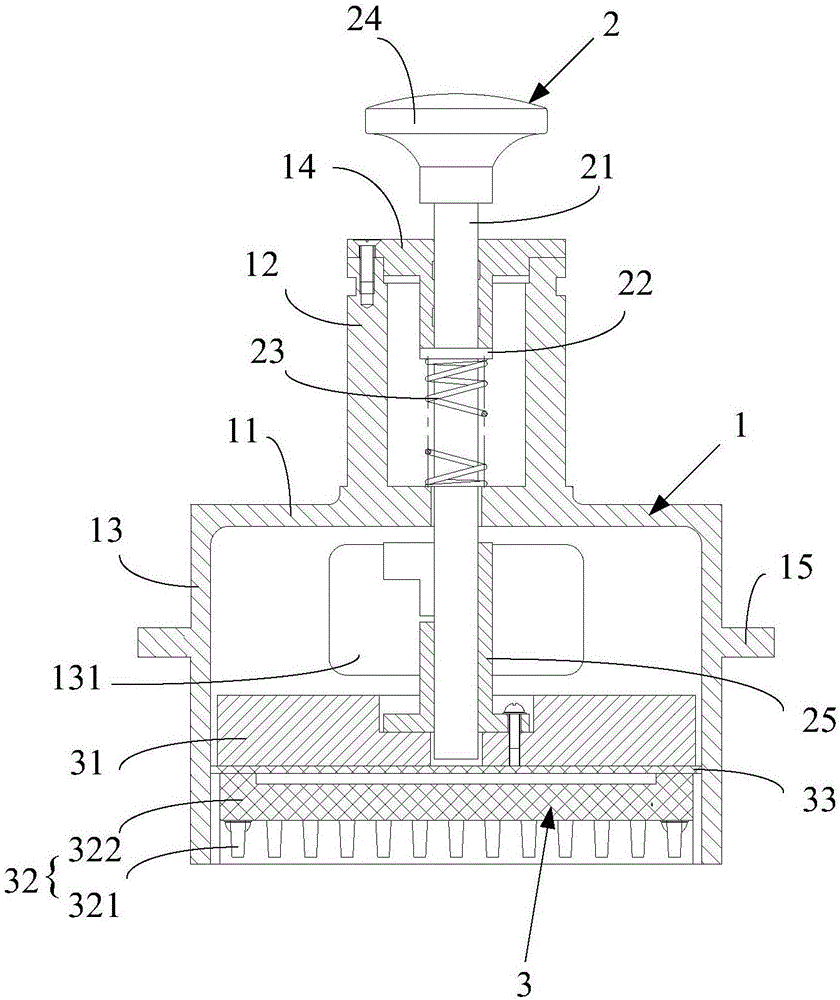

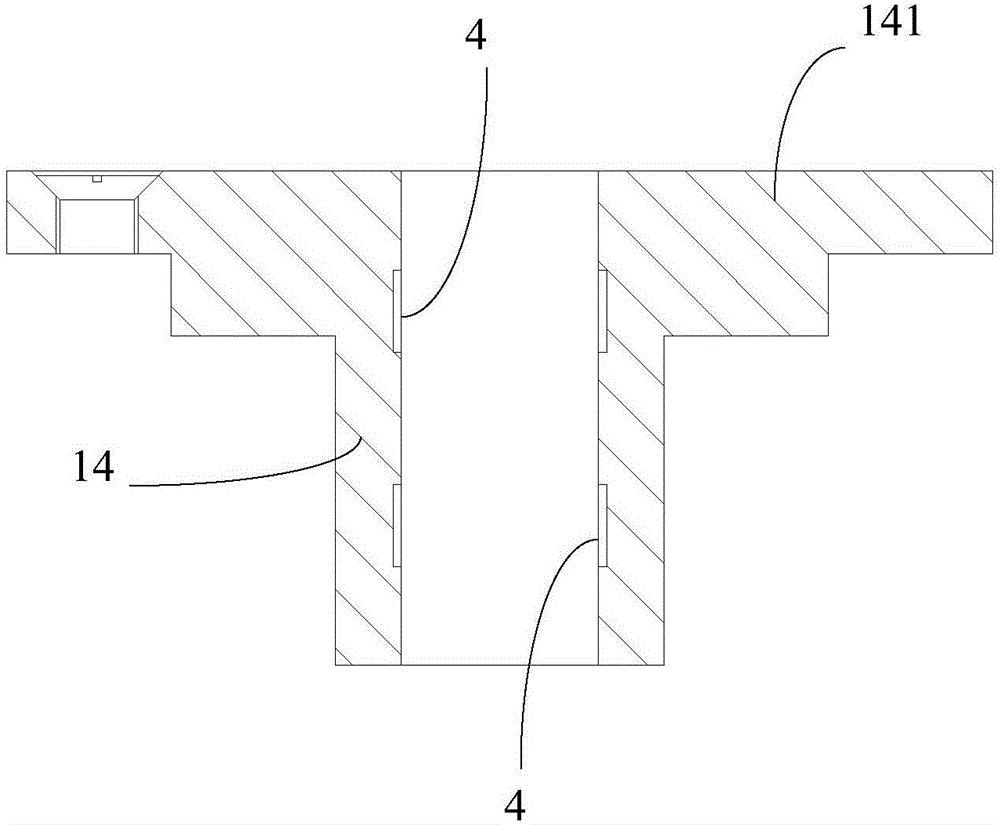

[0032] In this example, if figure 1 As shown, the cleaning device includes: a housing 1, an operating assembly 2 and a cleaning assembly 3, the housing 1 is fixedly installed on a support structure, and the housing 1 includes an end plate 11, a first cylinder 12, a second cylinder 13 and Limiting sleeve 14, one end of the first cylindrical body 12 is vertically fixed on one side of the end plate 11, the limiting sleeve 14 is fixedly installed on the other end of the first cylindrical body 12, and one end of the second cylindrical body 13 is vertically fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com