Horizontal grooving machine combined roller core device

A rolling grooving machine and combined technology, applied in the direction of feeding device, positioning device, peeling device, etc., can solve the problems of stuck battery, affecting the output pass rate, and battery throwing away, so as to improve the quality of sealing and improve production Efficiency and output pass rate, the effect of reducing the flare diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

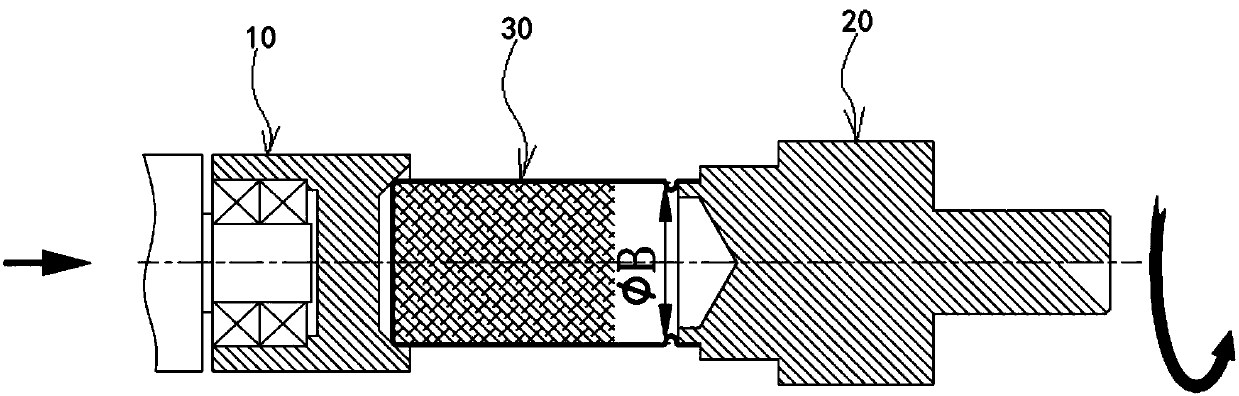

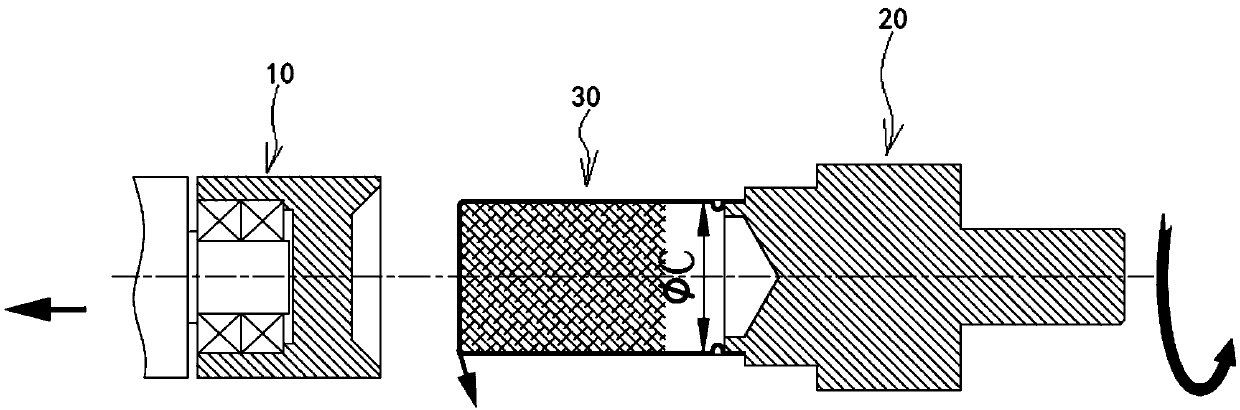

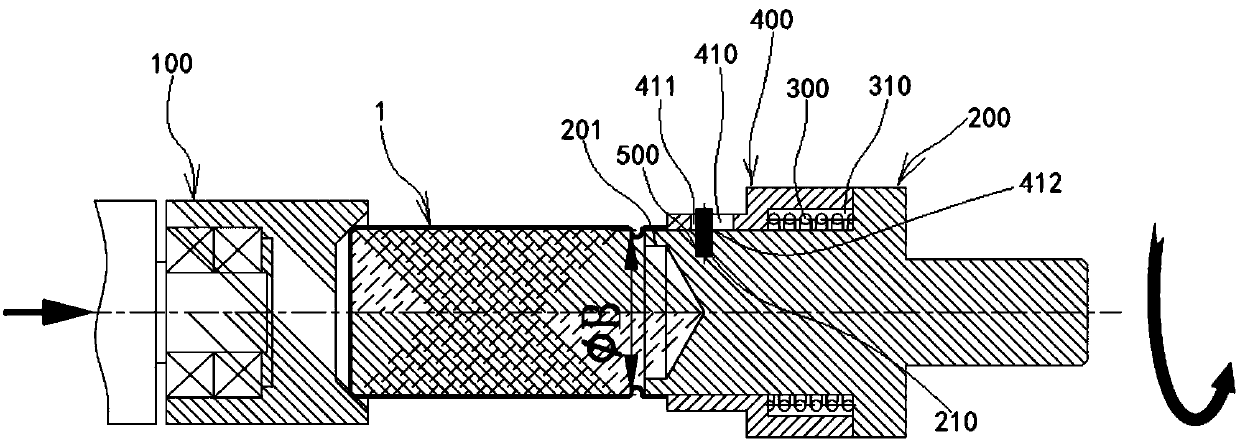

[0020] see image 3 and Figure 4 The combined rolling core device of the horizontal rolling groove machine shown includes a top core 100 and a rolling core 200 , and a telescopic sleeve 400 is provided on the outer peripheral surface of the processed end surface 201 of the rolling core 200 through an elastic member 300 .

[0021] In this embodiment, the inner wall of the telescopic sleeve 400 and the outer peripheral surface of the roller core 200 form a limiting cavity 310 that jointly limits the expansion and contraction of the elastic member 300 . The roller core 200 is provided with a limiting pin hole 210 , and the telescopic sleeve 400 is provided with a limiting groove 410 corresponding to the limiting pin hole 210 , and a limiting pin 500 passes through the limiting pin h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com