Quick clamping jig for grinding machine of pin wheel housing tooth slot of robot joint precision reducer

A precision reducer and robot joint technology, applied in the direction of grinding workpiece support, etc., can solve the problems of low efficiency, long workpiece installation and clamping time, auxiliary time prolonging product processing time, etc., to achieve fast and convenient clamping and save manufacturing costs , Guarantee the effect of product processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

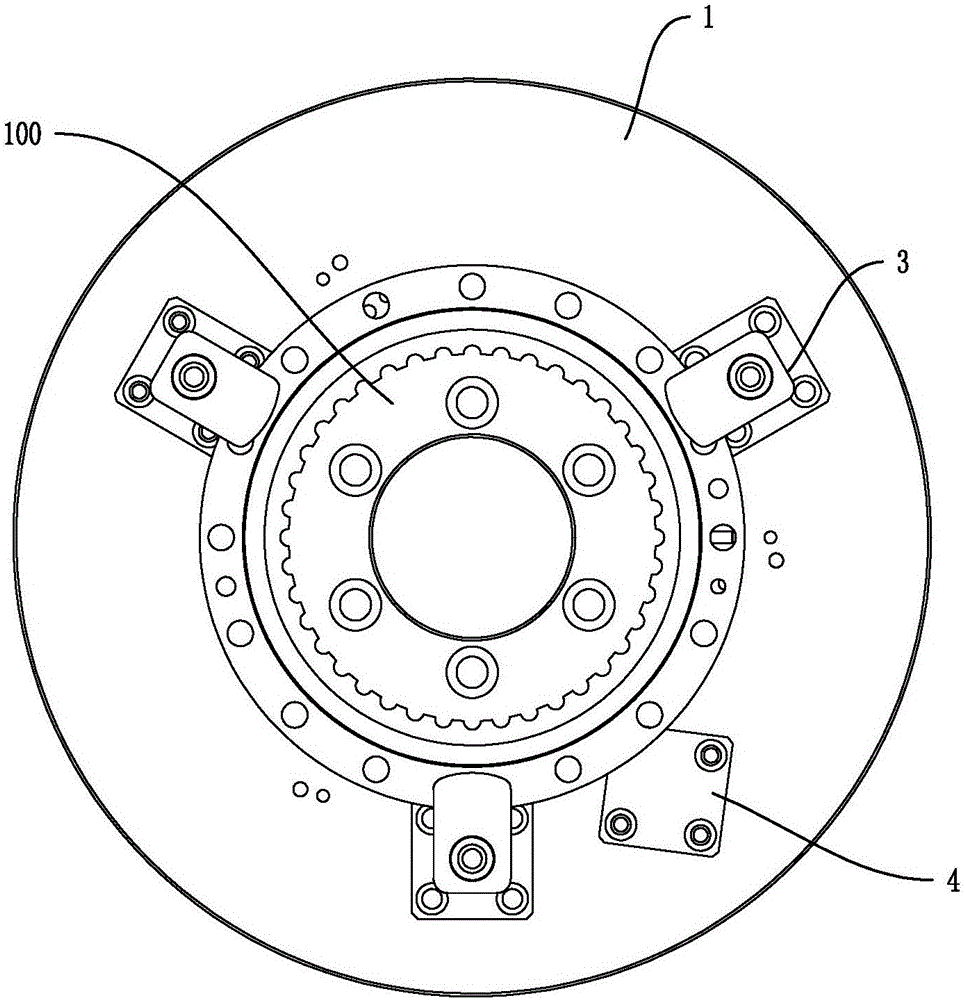

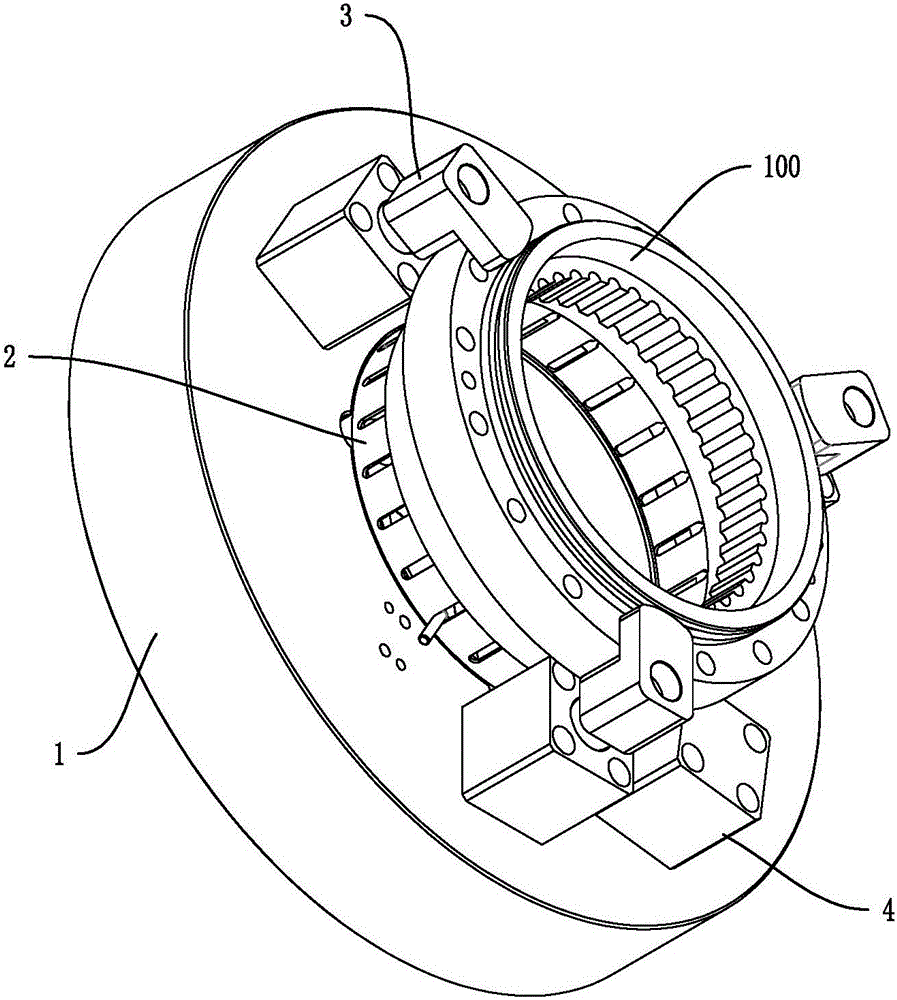

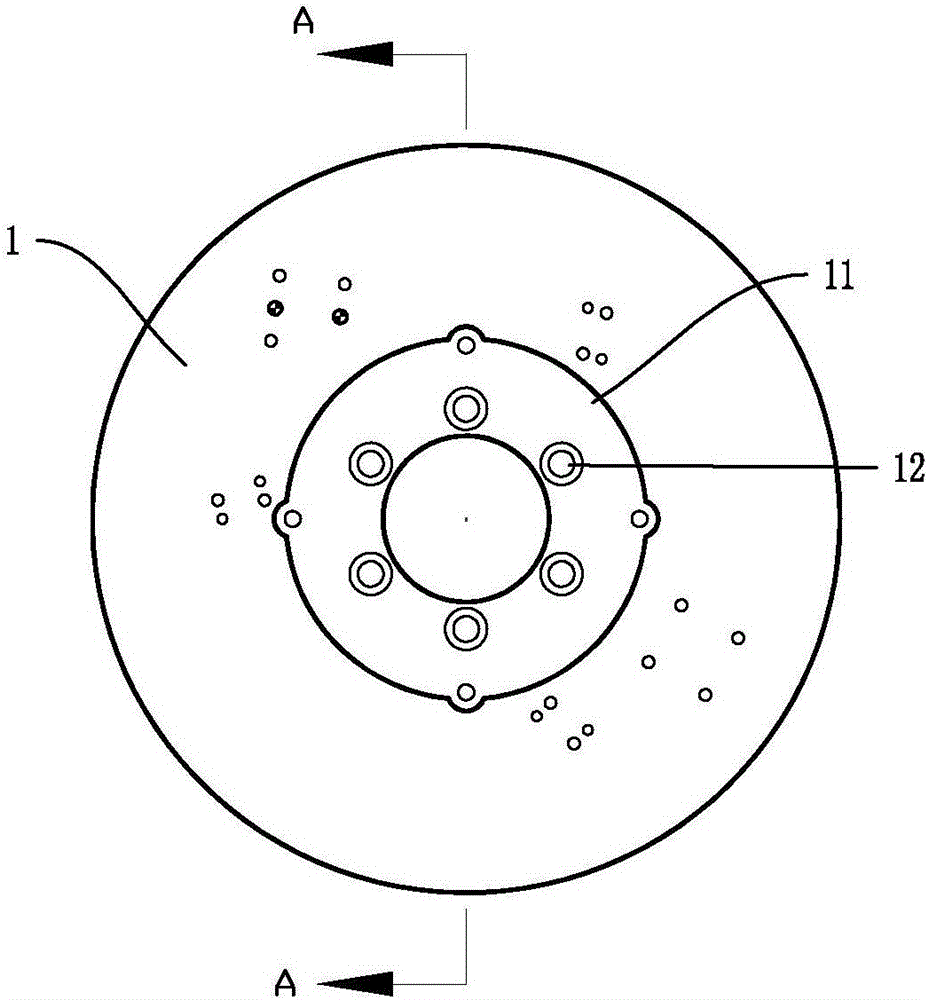

[0028] Such as figure 1 with figure 2 The quick clamping fixture for the pin gear shell tooth groove grinder of the robot joint precision reducer shown includes a guide base 1 and a workpiece fixture detachably fixed on the guide base 1 . The guide base 1 can have a degree of freedom of translation or rotation, so as to drive the workpiece clamp to reach the bottom of the pin gear housing workpiece, so as to cooperate with fast clamping. In the embodiments described below, the guide base 1 is mounted on a rotating seat not shown in the figure, and the workpiece fixture is driven to a proper position through rotation.

[0029] The difference from the prior art is that the workpiece clamp in the embodiment positions and clamps the outer wall of the pin gear housing workpiece 100 in an adaptive manner. The self-adaptation refers to that the workpiece fixture can adapt to the change of its shape during the process of putting in and taking out the workpiece. Through this self-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com