Tire die for producing precure tread

A technology for tire molds and pre-vulcanized tires, applied in the field of retreaded tires, can solve the problems of high investment cost, strong specialization of vulcanization equipment and special molds, etc., and achieves the effects of high investment cost, increased use and long cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

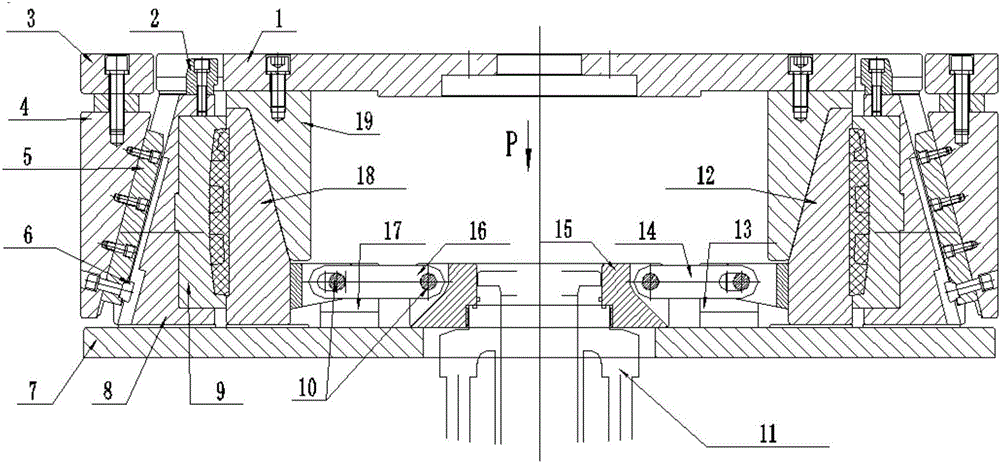

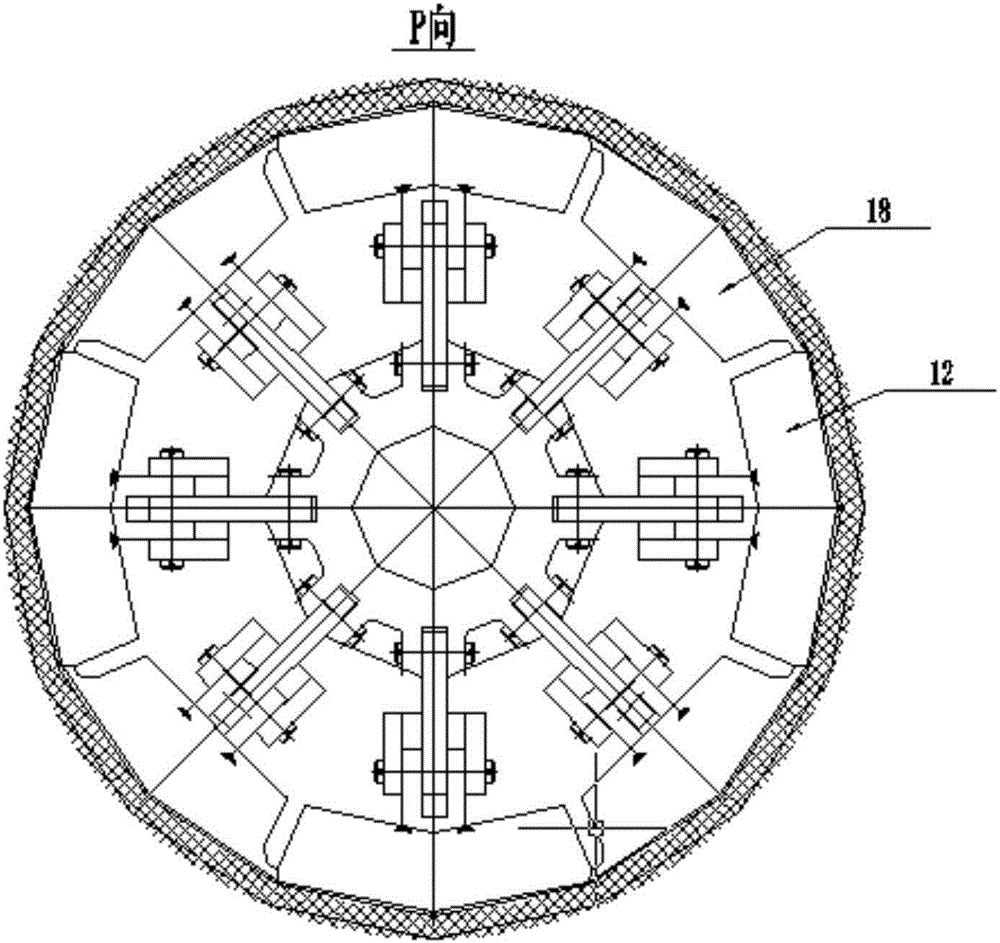

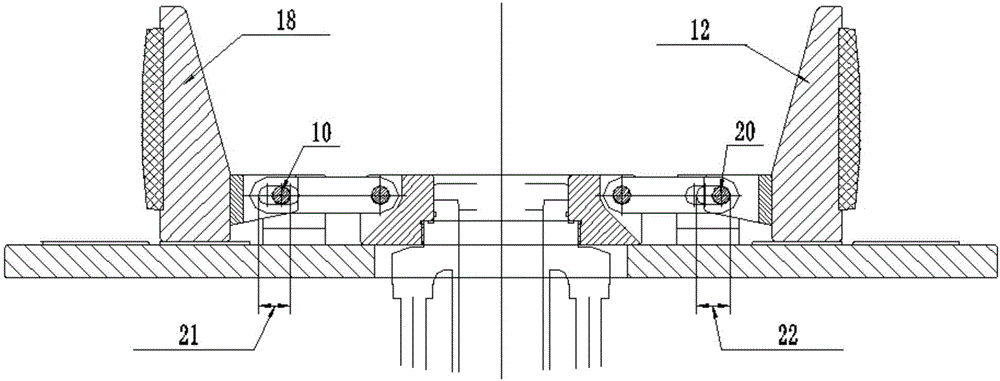

[0044]First of all, the mold of the present invention mainly consists of two parts: an outer active part and an inner active part. The outer active part mainly includes: upper cover 1, installation ring 3, guide ring 4, slider 8, base 7, pattern block 9, upper sliding Block 2, guide strip 5, limit block 6; the inner active part mainly includes inner ring 19, inner active blocks I18 and II12, hinge seats I17 and II13, push-pull plates I16 and II14, control ring 15, see figure 1 , 2 , image 3 , Figure 4 ; When used as a whole, the installation ring of the mold is connected with the upper plate of the vulcanizer, the upper cover is connected with the driving mechanism of the active mold of the vulcanizer, and the base is connected with the lower plate of the vulcanizer.

[0045] The outer active part is the same as the general tire mould, and this part of the tire tire mold can be borrowed during use. This mold can be vulcanized by using an ordinary tire shaping vulcanizer. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com