Wall-attaching type hoisting hanging bracket capable of achieving horizontal large-angle stepless adjustment

A stepless adjustment, large-angle technology, applied in cranes and other directions, can solve the problems of high hoisting difficulty, inability to guarantee safety, and no generalizability, and achieve the effect of reducing time costs and improving hoisting speed and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

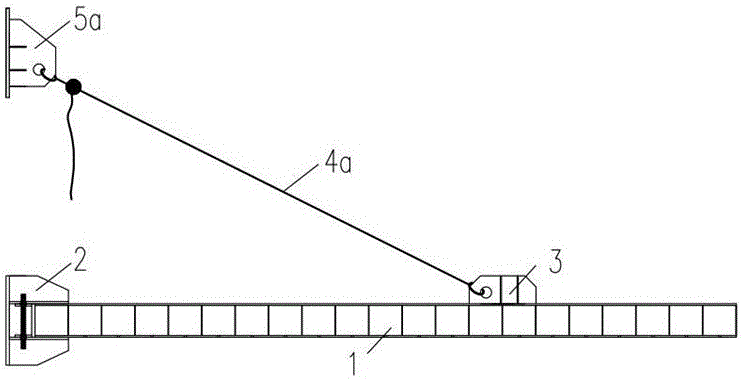

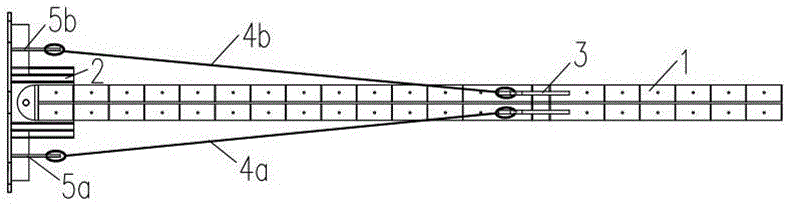

[0017] Embodiment 1: In the present invention, a wall-mounted hoisting hanger with a large horizontal angle steplessly adjustable includes a cantilever steel beam 1, a cantilever steel beam base 2, a first suspension cable 4a, a second suspension cable 4b, a first Suspension cable base 5a, second suspension cable base 5b and connection node 3. The cantilever steel beam 1 is fixed on the wall through the cantilever steel beam base 2 . The first suspension cable 4a and the second suspension cable 4b are located on both sides of the cantilever steel beam 1 respectively, and one end of the first suspension cable 4a and the second suspension cable 4b is respectively connected to the cantilever steel beam 1 through the connecting node 3, and the first suspension cable 4a and the other end of the second suspension cable 4b are respectively connected to the wall through the first suspension cable base 5a and the second suspension cable base 5b. The connecting node 3 is located on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com