An anchoring structure and construction method of interlaced tensioning tendons of prestressed tendons at end-column-beam joints

A technology of prestressed tendons and construction methods, which is applied to building structures, building components, structural elements, etc., can solve the problems of low hoisting speed and accuracy, poor resistance to negative bending moments of nodes, and undeveloped problems, so as to improve the hoisting speed. It has the effect of good precision, anti-negative bending moment and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

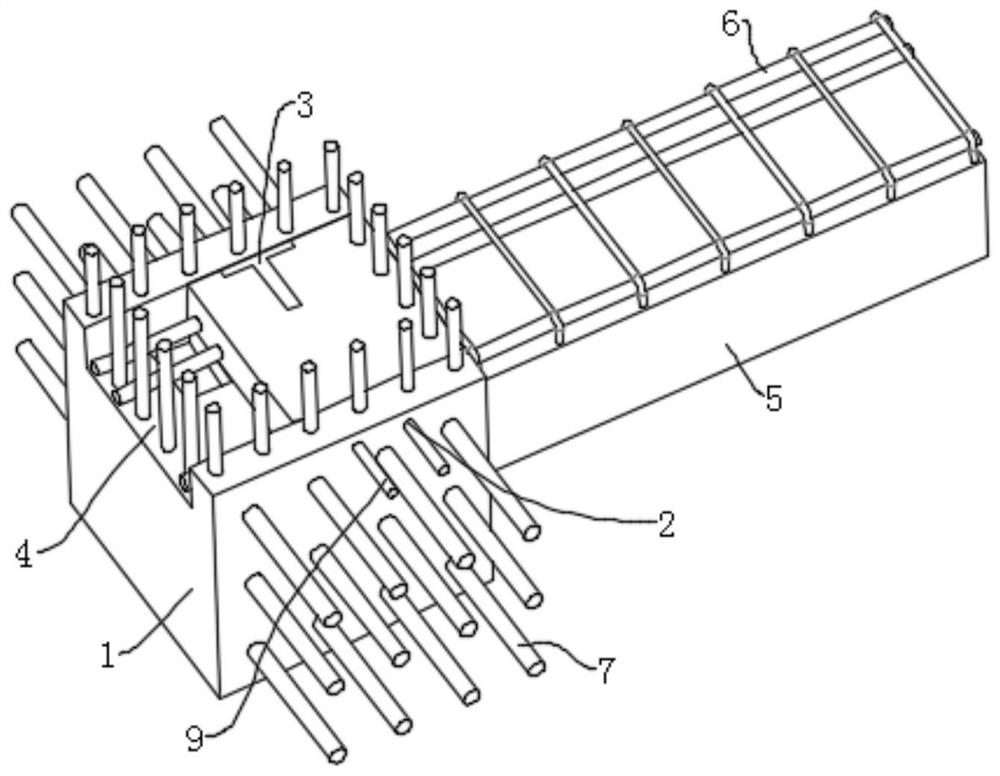

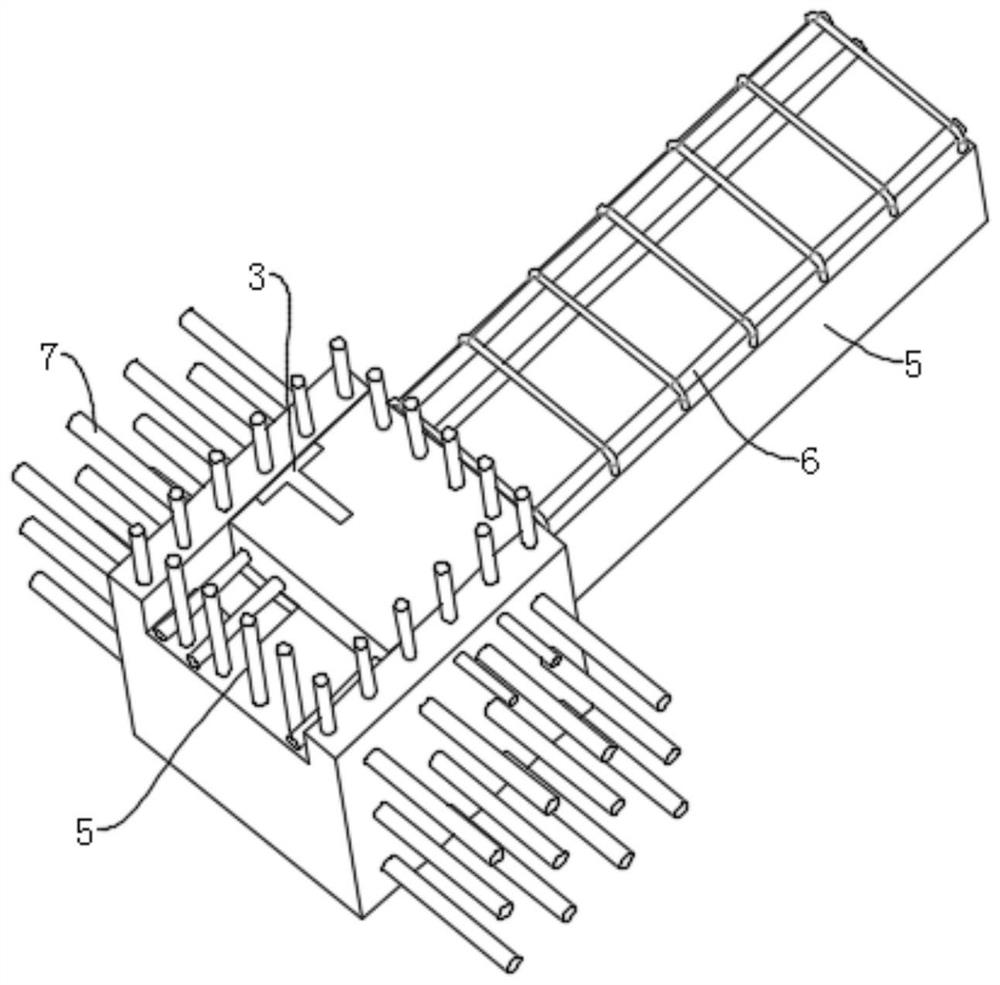

[0050] A prefabricated building prefabricated steel concrete end column-beam joint prestressed tendon interlaced tension anchor structure, including prefabricated column 1, also includes:

[0051] The reserved channel 2 reserved in the prefabricated column 1;

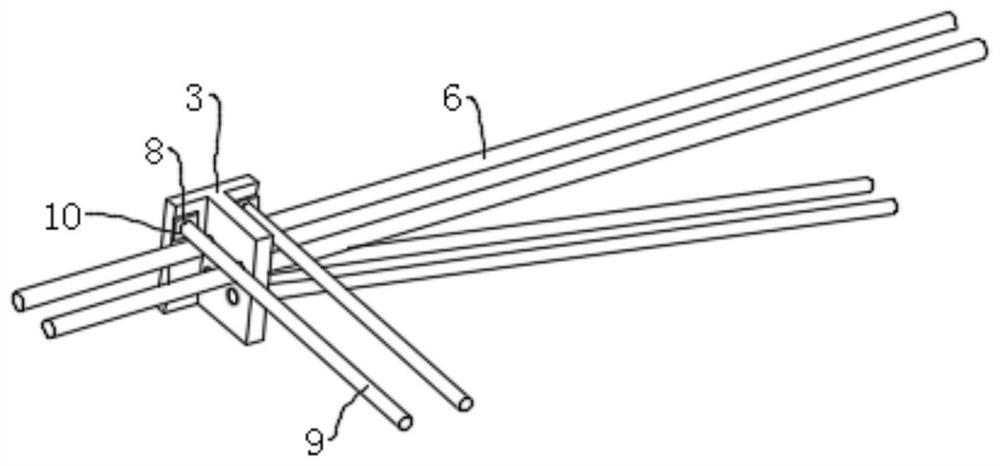

[0052] T-shaped steel column 3 integrally formed with prefabricated column 1;

[0053] The prefabricated column laminated layer 4 arranged on the upper part of the prefabricated column 1;

[0054] A composite beam 5 arranged at one end of the prefabricated column 1;

[0055] The top steel bar 6 exposed on the upper part of the composite beam 5;

[0056] The outstretched steel bar 7 extending from the side of the prefabricated column 1;

[0057] A plurality of reserved perforations 8 provided on the T-shaped steel column 3;

[0058] Prestressed tendons 9 passing through a plurality of reserved perforations 8;

[0059] The prestressed tendon 9 anchoring device fixed on the T-shaped steel column 3, the prestressed ten...

Embodiment 2

[0063] The difference from Embodiment 1 is that it also provides a construction method for assembling prefabricated steel concrete end column-beam joint prestressed tendon cross-tensioned anchorage structure, which specifically includes the following steps:

[0064] a. The factory makes prefabricated columns 1;

[0065] b. Prefabricated column 1 hoisting construction;

[0066] c. Hoisting of composite beam 5 and installation of support system;

[0067] d. Sleeve grouting connection of prefabricated column 1 side extension steel bar 7 at the post-casting section of beam-column joint;

[0068] e. Installation of formwork and support system at the post-casting section of beam-column joints;

[0069] f. The three-direction prestressed tendon 9 is perforated and temporarily fixed;

[0070] g. Concrete pouring at the post-cast section of beam-column joints;

[0071] h. Tensioning and anchoring of prestressed steel bars in three directions;

[0072] j. Install and fix the flat d...

Embodiment 3

[0088] The difference from Example 2 lies in the construction method for assembling the prefabricated steel concrete end column beam joint prestressed tendon interlaced tension anchorage structure, which specifically includes the following steps:

[0089] a. The factory makes prefabricated columns 1;

[0090] b. Prefabricated column 1 hoisting construction;

[0091] c. Hoisting of composite beam 5 and installation of support system;

[0092] d. Sleeve grouting connection of prefabricated column 1 side extension steel bar 7 at the post-casting section of beam-column joint;

[0093] e. Installation of formwork and support system at the post-casting section of beam-column joints;

[0094] f. The three-direction prestressed tendon 9 is perforated and temporarily fixed;

[0095] g. Concrete pouring at the post-cast section of beam-column joints;

[0096] h. Tensioning and anchoring of prestressed steel bars in three directions;

[0097] j. Install and fix the flat dark beam st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com