Solar highway snow melting system

A technology of solar energy and solar panels, applied in the field of solar power generation, can solve problems such as road surface damage, snow removal salt corrosion, soil, water body and air pollution, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further illustrated by specific examples below, but it should be understood that these examples are only used for more detailed description, and should not be construed as limiting the present invention in any form.

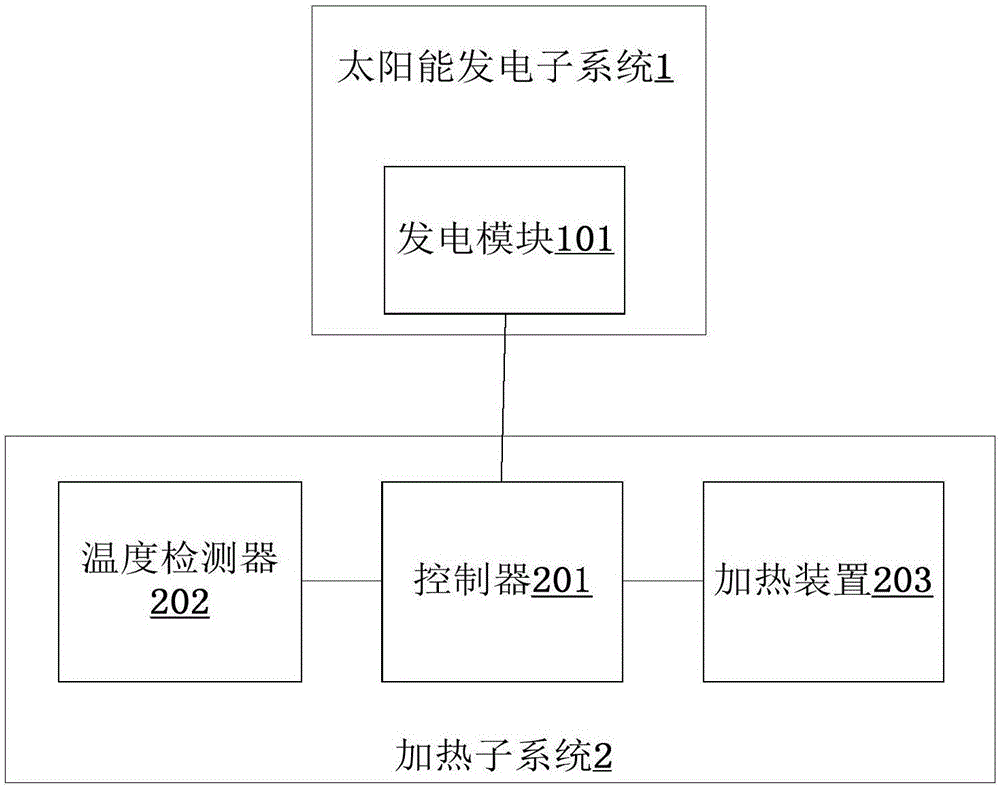

[0046] to combine figure 1 , the solar road snow melting system provided by the present embodiment includes a solar power generation subsystem 1 and a heating subsystem 2;

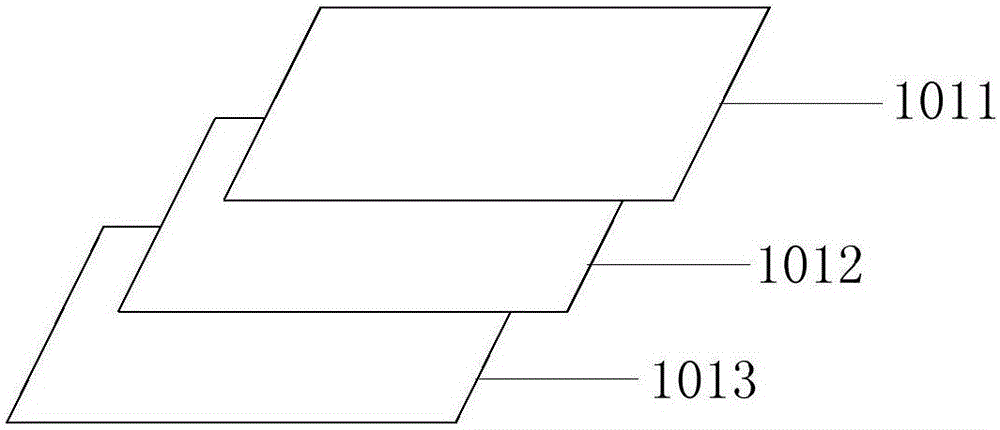

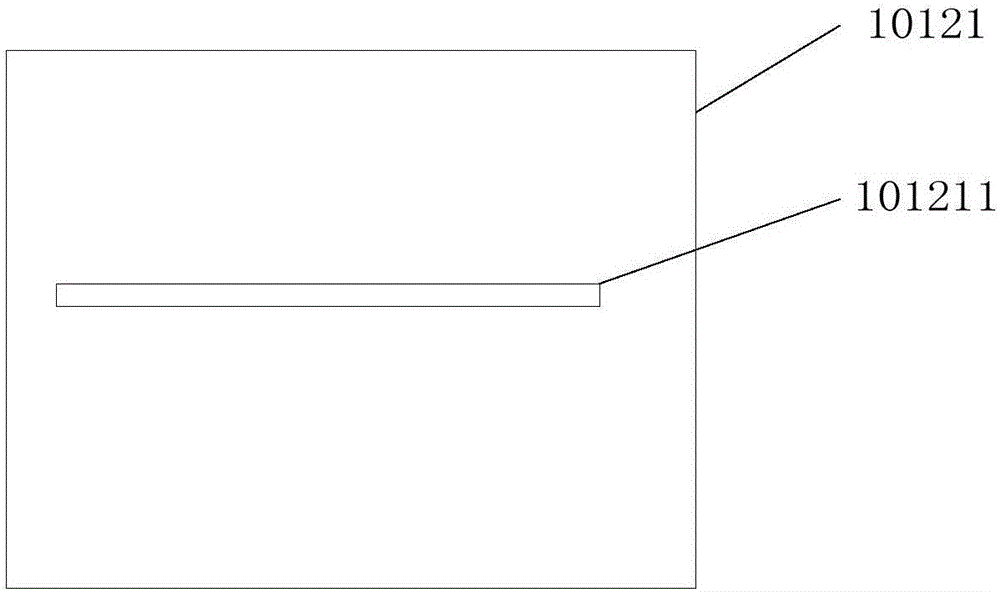

[0047] The solar power generation subsystem 1 is laid on the road, and includes at least one power generation module 101, each power generation module 101 has a unique ID code, and a drain tank is left between every two power generation modules 101, such as figure 2 As shown, each power generation module 101 has a three-layer structure, and from top to bottom is a transparent load-bearing layer 1011, a solar cell group layer 1012, and an aquifer layer 1013;

[0048] Among them, the transparent load-bearing layer 1011 is used to carry the vehicles passing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com