Anti-icing cylindrical pressure probe

A probe and cylindrical technology, which is applied in the field of anti-icing cylindrical pressure probes, can solve problems such as icing of cylindrical probes, and achieve the effects of preventing icing problems, ensuring accuracy and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

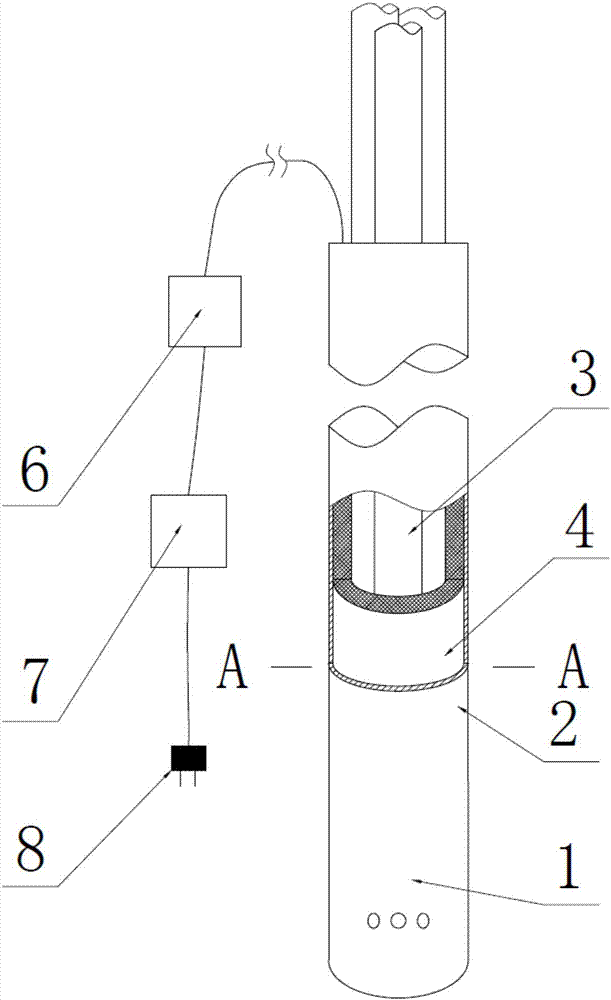

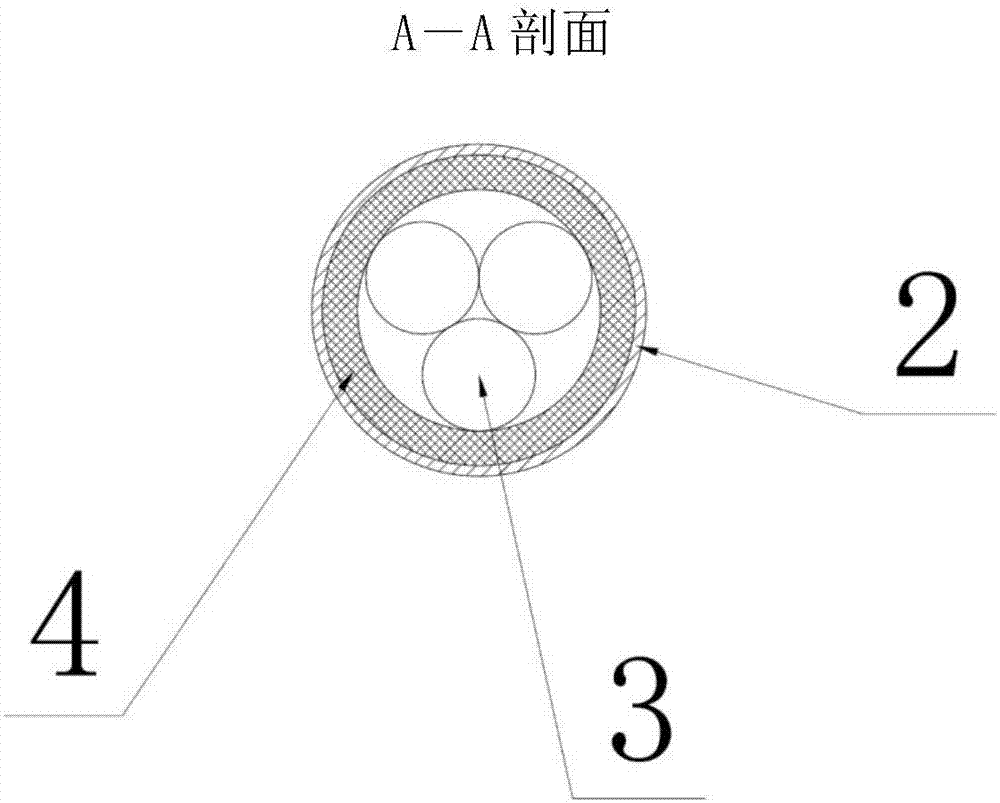

[0027] Such as figure 1 , figure 2 and image 3 As shown, an anti-icing column-shaped pressure probe is introduced in this embodiment, which includes a probe head (1), a probe rod (2), and a pressure introduction tube (3); the anti-icing column-shaped pressure probe The needle is a columnar structure, and the pressure-sensing hole on the head can be single-hole, double-hole, three-hole or four-hole structure; the probe rod (2) is a hollow sleeve rod, and the end of the probe is provided with a probe head (1) , the probe head (1) is welded to the probe rod (2), and the probe head (1) blocks the hollow part of the probe rod (2); the middle sleeve pressure guide tube (3) of the probe rod, Each pressure induction tube (3) is brazed together and extends in a direction parallel to the axis of the probe rod (2), and the end of each pressure induction tube (3) is inserted into the pressure sensing tube of the probe head (1). holes and welded together.

[0028] In this embodiment,...

Embodiment 2

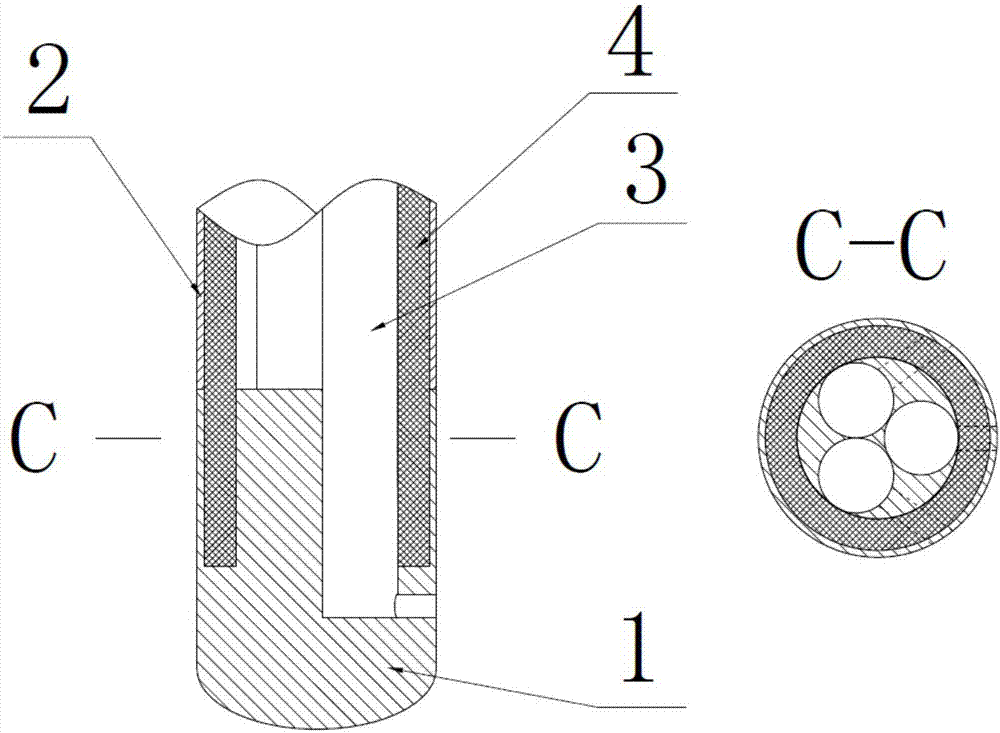

[0035] Such as Figure 4 , Figure 5 and Figure 6 As shown, an anti-icing column pressure probe is introduced in this embodiment, which includes a probe head (1), a probe rod (2), and a pressure introduction tube (3); the anti-icing column-shaped pressure probe The needle is a columnar structure, and the pressure-sensing hole on the head can be single-hole, double-hole, three-hole or four-hole structure; the probe rod (2) is a hollow sleeve rod, and the end of the probe is provided with a probe head (1) , the probe head (1) is welded to the probe rod (2), and the probe head (1) blocks the hollow part of the probe rod (2); the middle sleeve pressure guide tube (3) of the probe rod, Each pressure induction tube (3) is brazed together and extends in a direction parallel to the axis of the probe rod (2), and the end of each pressure induction tube (3) is inserted into the pressure sensitive tube of the probe head (1). holes and welded together.

[0036]In this embodiment, ele...

Embodiment 3

[0042] This embodiment is based on any one of the above-mentioned embodiments one and two, and also has the following technical features: the tail of the heating film (4) or the heating rod (5) is wired to pass through the probe rod (2), and the terminal that passes through The part is provided with a plug (8) connected to the power supply.

[0043] Through the above settings, the heating film (4) or heating rod (5) of the cylindrical pressure probe is connected to the external power supply through the wiring provided with the plug (8), so as to realize the heating of the heating film (4) or the heating rod (5). The rod (5) serves the purpose of heating the power supply.

[0044] In this embodiment, in order to improve the accuracy of the heating control of the cylindrical pressure probe, a temperature control device (6) is provided on the wiring between the tail of the heating film (4) or the heating rod (5) and the plug (8). , transformer (7); described temperature control ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com