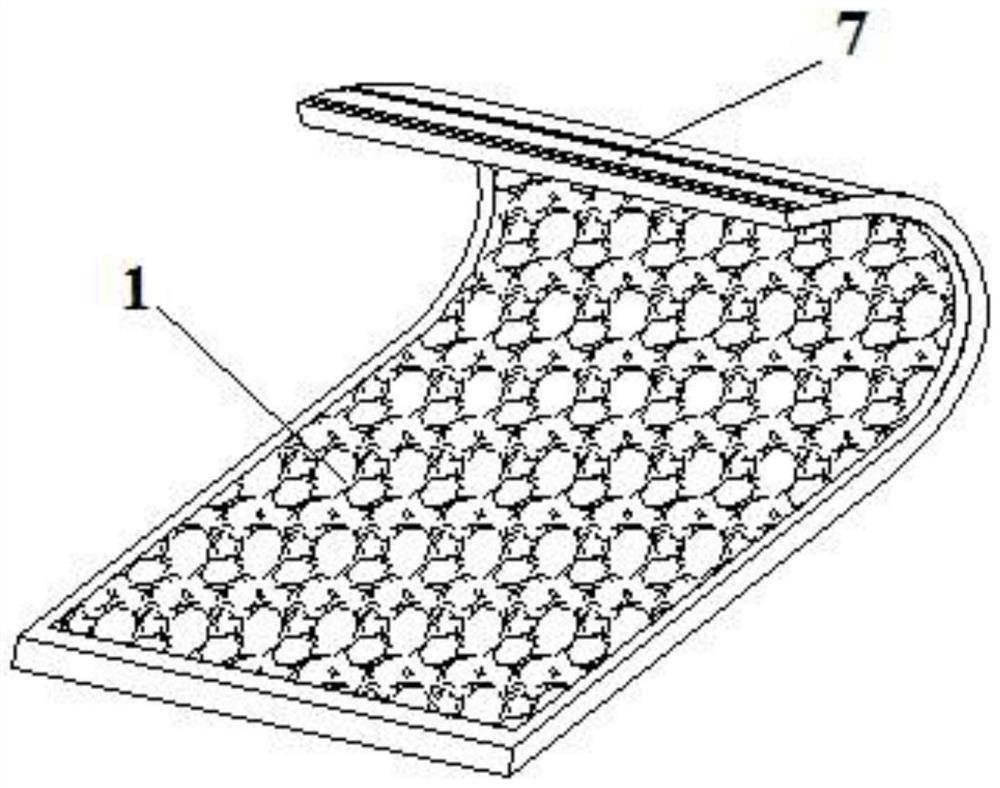

A snow-melting blanket based on piezoelectric power generation

A piezoelectric power generation and snow melting technology, applied in battery circuit devices, current collectors, electric vehicles, etc., can solve the problems of large power consumption, poor immediacy of snow melting, etc., achieve high energy conversion efficiency, easy splicing, disassembly and replacement, The effect of preventing side extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

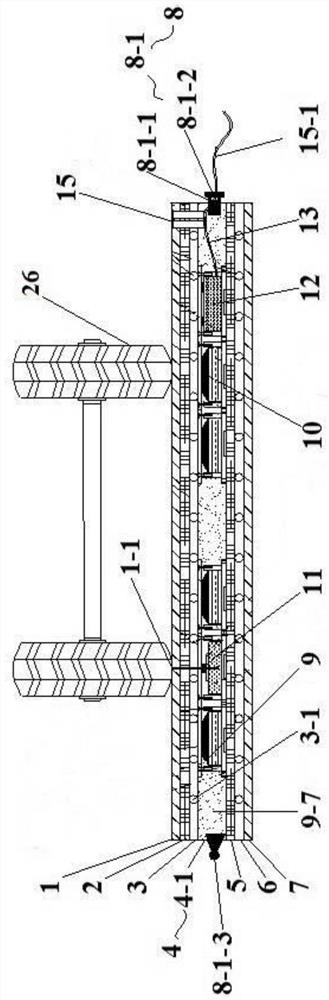

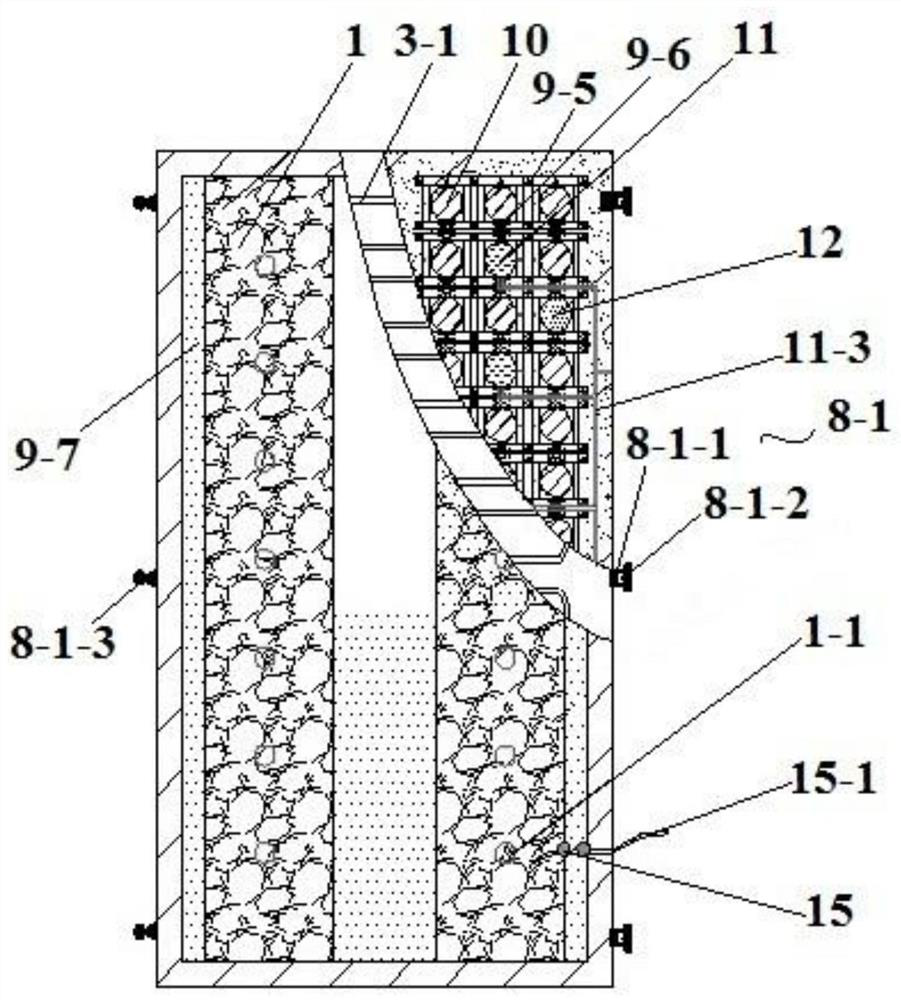

Embodiment 1

[0073] The piezoelectric power generation layer 4 is a steel plate type piezoelectric power generation layer 4-1.

Embodiment 2

[0092] The piezoelectric power generation layer 4 is a substrate type piezoelectric power generation layer 4-2.

[0100] The substrate-type piezoelectric generator 17 is installed in the installation groove 16-1, and the substrate-type piezoelectric generator 17 is

[0101] The substrate type piezoelectric generator 17 includes a first hard rubber pad installed at the bottom of the installation groove 16-1

[0104] The top of the first force transmission member 17-3 is slightly higher than the top of the base plate 16, and this height setting can make the base plate 16

[0105] The side of the substrate-type piezoelectric power generation layer 4-2 is equipped with a second red and green diode 20, and the second red and green diode

Embodiment 3

[0108] The piezoelectric power generation layer 4 is a rubber substrate type piezoelectric power generation layer 4-3.

[0114] Specifically, the described snow melting blankets are connected by connecting members 8, and the connecting members 8 are common connecting members 8-2,

[0116] The rubber substrate type piezoelectric generator 23 is installed in the rubber limit groove 21-1, and the rubber substrate type piezoelectric generator is

[0117] The rubber substrate type piezoelectric generator 23 includes a second hard plate mounted on the bottom of the rubber limit groove 21-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com