Conductive concrete, preparing method, heating system and method for melting ice and snow

A conductive concrete and conductive concrete slab technology, applied in the field of conductive concrete, can solve the problems of high cost, low efficiency, damage to road surface and bridge structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

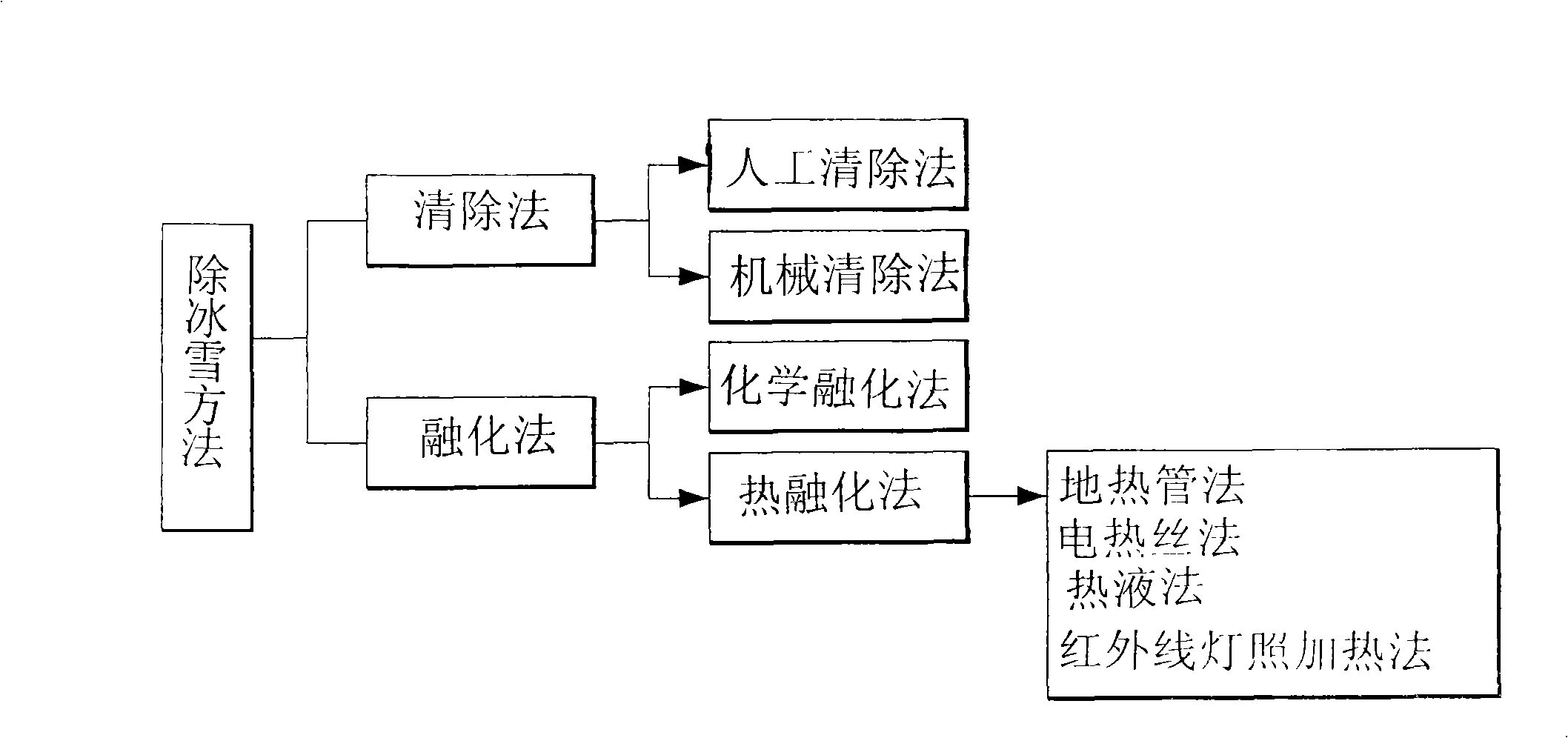

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

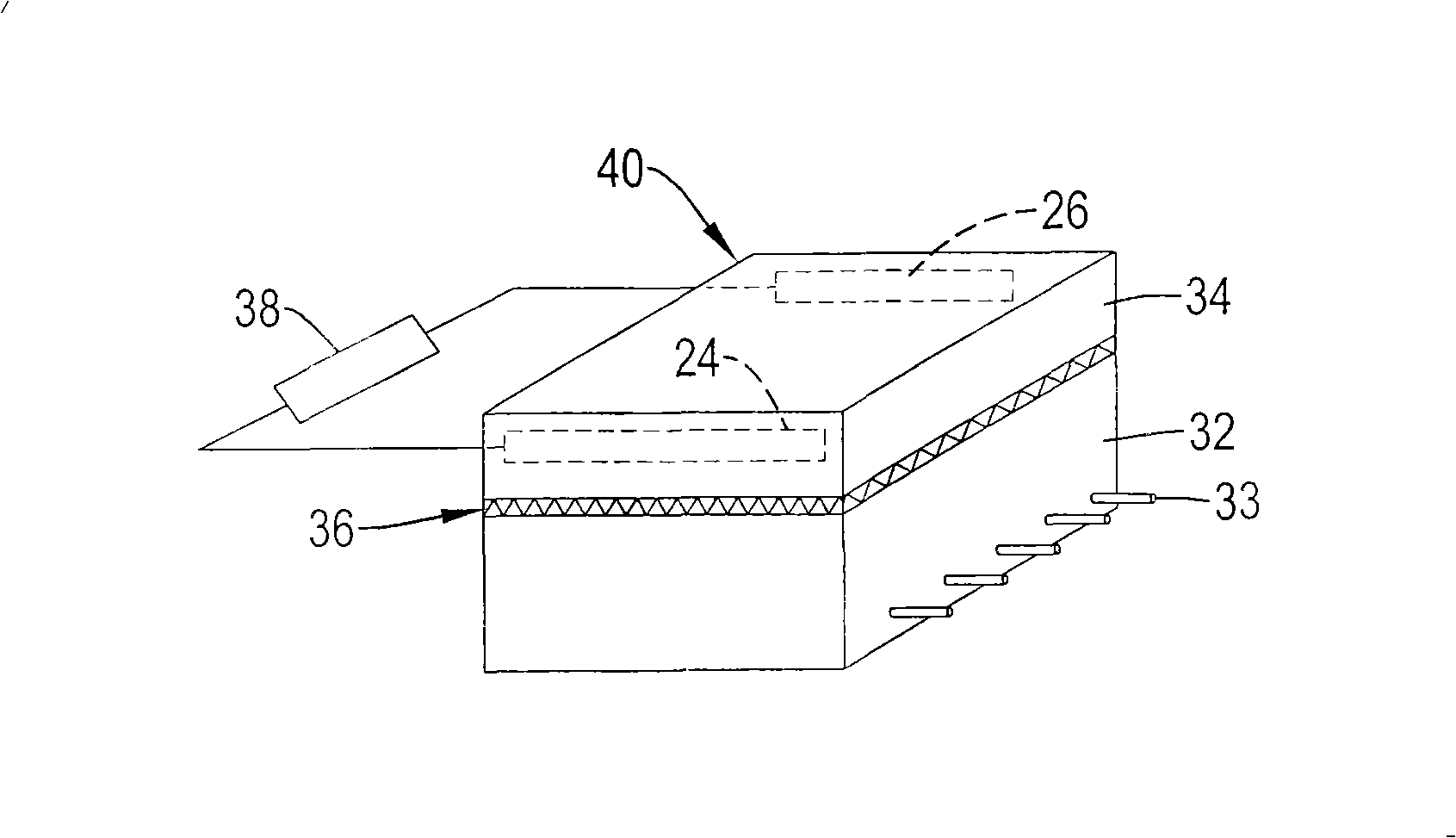

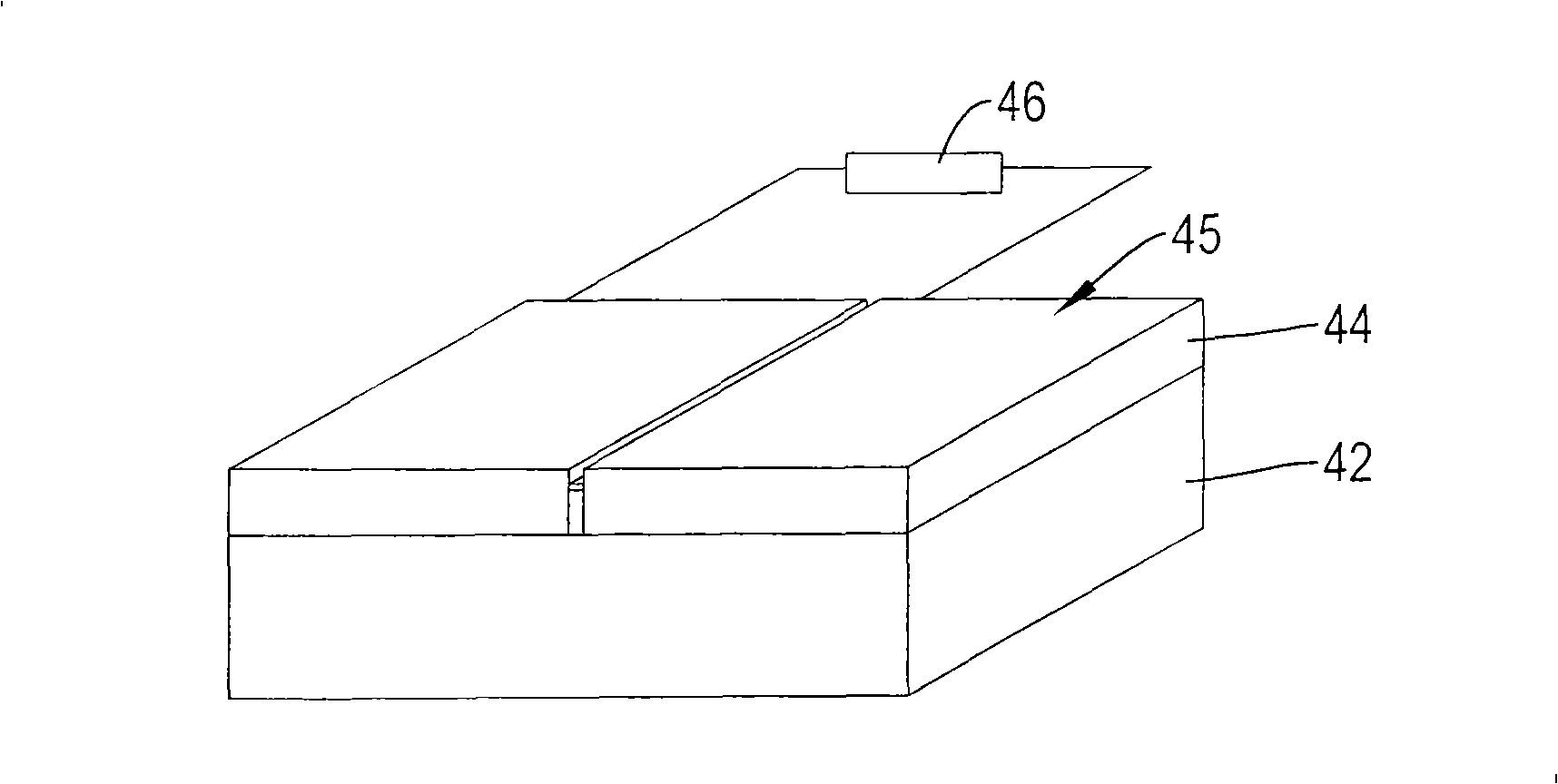

[0034] The deicing system of the present invention comprises five parts such as (1) conductive concrete, (2) conductive material, (3) electrode, (4) power source, (5) control system, now respectively describe as follows:

[0035] (1), conductive concrete

[0036]The conductive concrete of the present invention is formed by mixing cement, aggregate, water and conductive materials. The conductive concrete preferably uses the first type or the third type cement, and its volume accounts for 12-16% of the total volume (unless Specially specified, otherwise the percentage refers to the percentage of the total volume of the conductive concrete), and the best is that the cement accounts for 14-16% of the total volume of the conductive concrete. The best aggregate is to use 10-25% fine aggregate and 10-25% coarse aggregate, and the best is to use 13-18% and 17-20% fine aggregate and coarse aggregate respectively. Contains sand and gravel, preferably the equivalent of Nabraska No. 47B....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com