A steward type universal wave energy conversion device

A conversion device and wave energy technology, applied in ocean energy power generation, machines/engines, mechanical equipment, etc., can solve problems such as energy capture efficiency being greatly affected by wave direction, complex mechanical structure of power generation devices, and inability to absorb wave kinetic energy. , to achieve high energy capture efficiency, reduce oil pipe corrosion, and improve survivability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

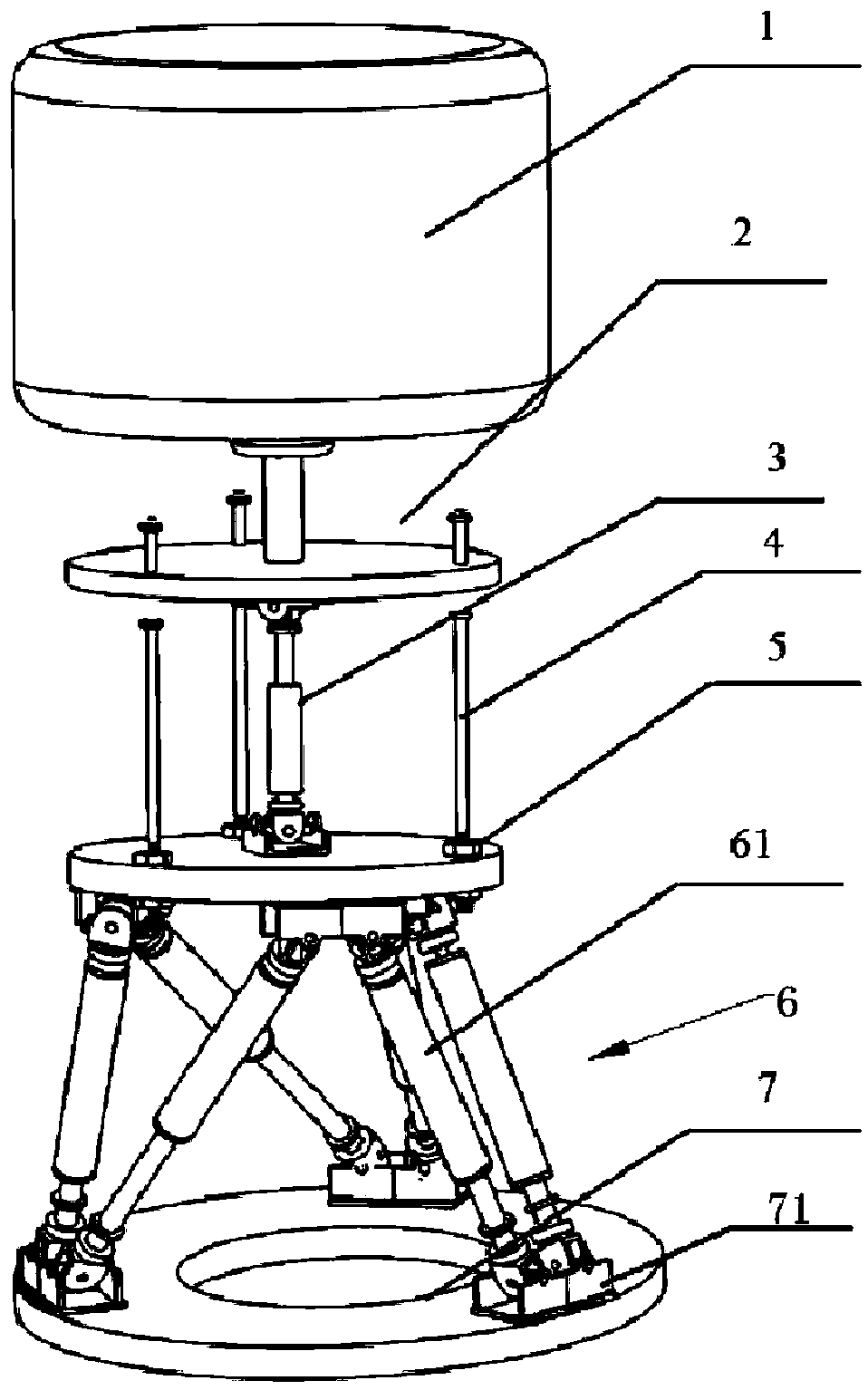

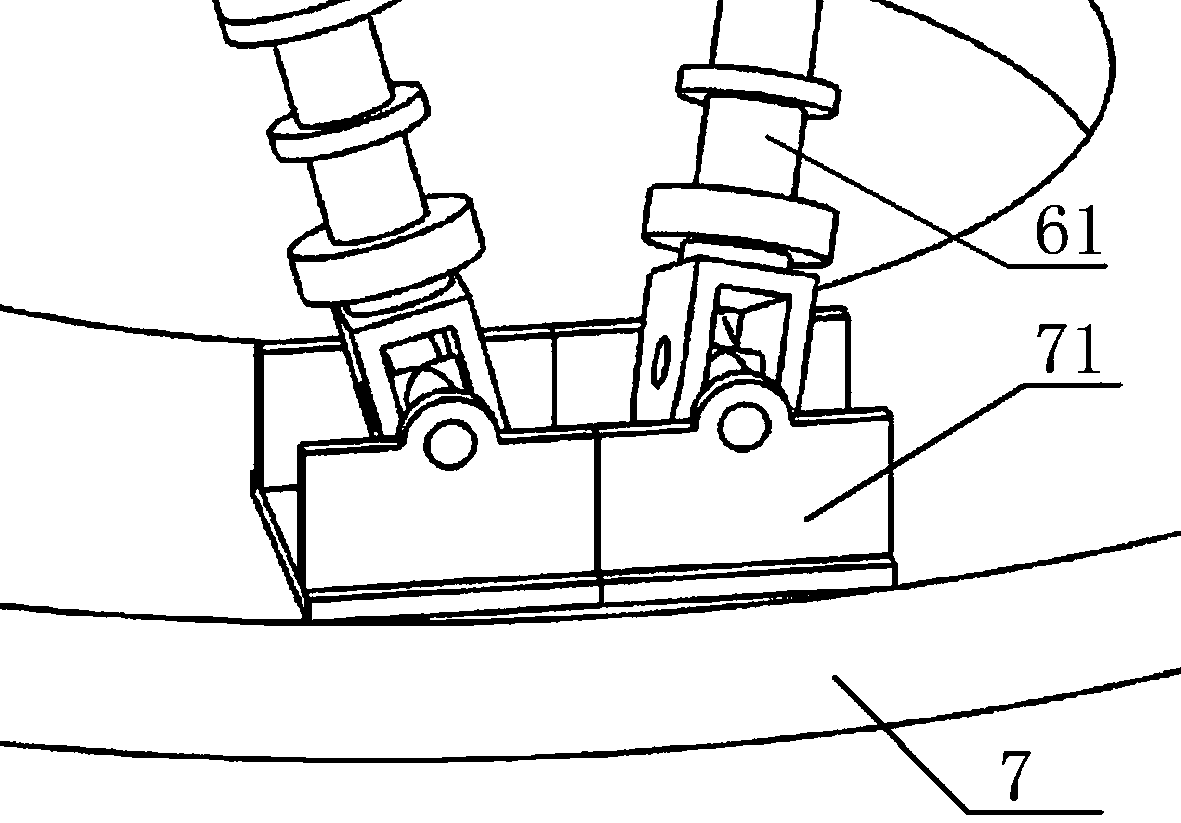

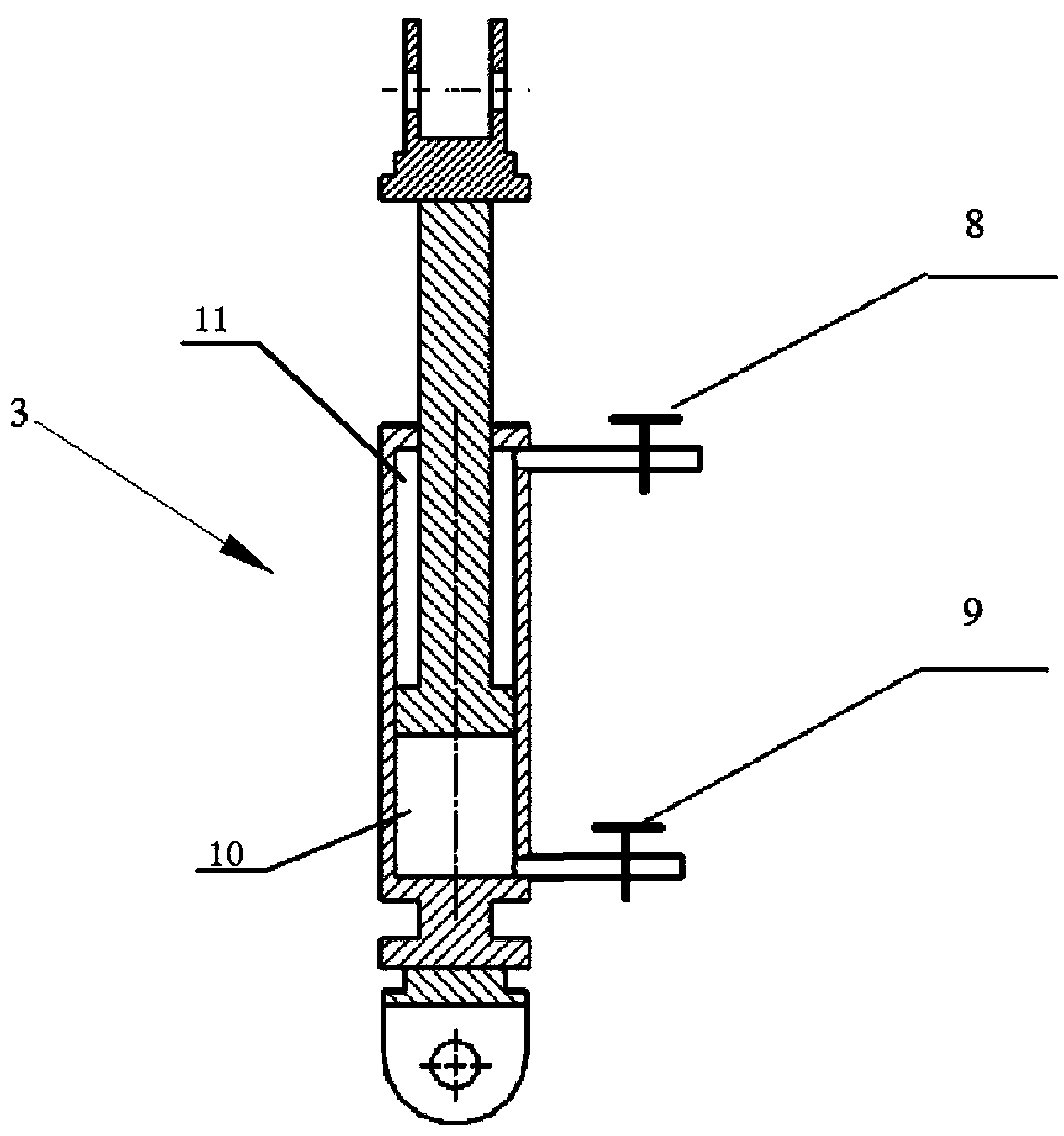

[0030] Such as figure 1 As shown, a steward-type universal wave energy conversion device includes a buoy 1, an adjustment platform 2, an adjustment cylinder 3, a guide rod group 4, and a steward parallel mechanism arranged sequentially from top to bottom; the steward parallel mechanism includes top to bottom The moving platform 5, the power generation hydraulic cylinder group or the cylindrical linear generator set 6 and the fixed platform 7 are arranged in sequence; the float 1 is rigidly connected to the adjusting platform 2, and one end of the adjusting cylinder 3 is hinged on the lower end of the adjusting platform 2, and the other end is hinged on the moving platform 5 The upper end; the guide rod group 4 is arranged between the adjustment platform 2 and the moving platform 5 to guide the adjustment platform 2 and the moving platform 5 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com