Photovoltaic-piezoelectric-electromagnetic compound type energy harvester

A composite, energy harvester technology, applied in photovoltaic power generation, photovoltaic power stations, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., can solve the problem of long-term power supply of electronic products or sensors that are difficult to meet low power consumption It can improve the conversion efficiency and scope of application, have strong environmental adaptability, and overcome poor compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

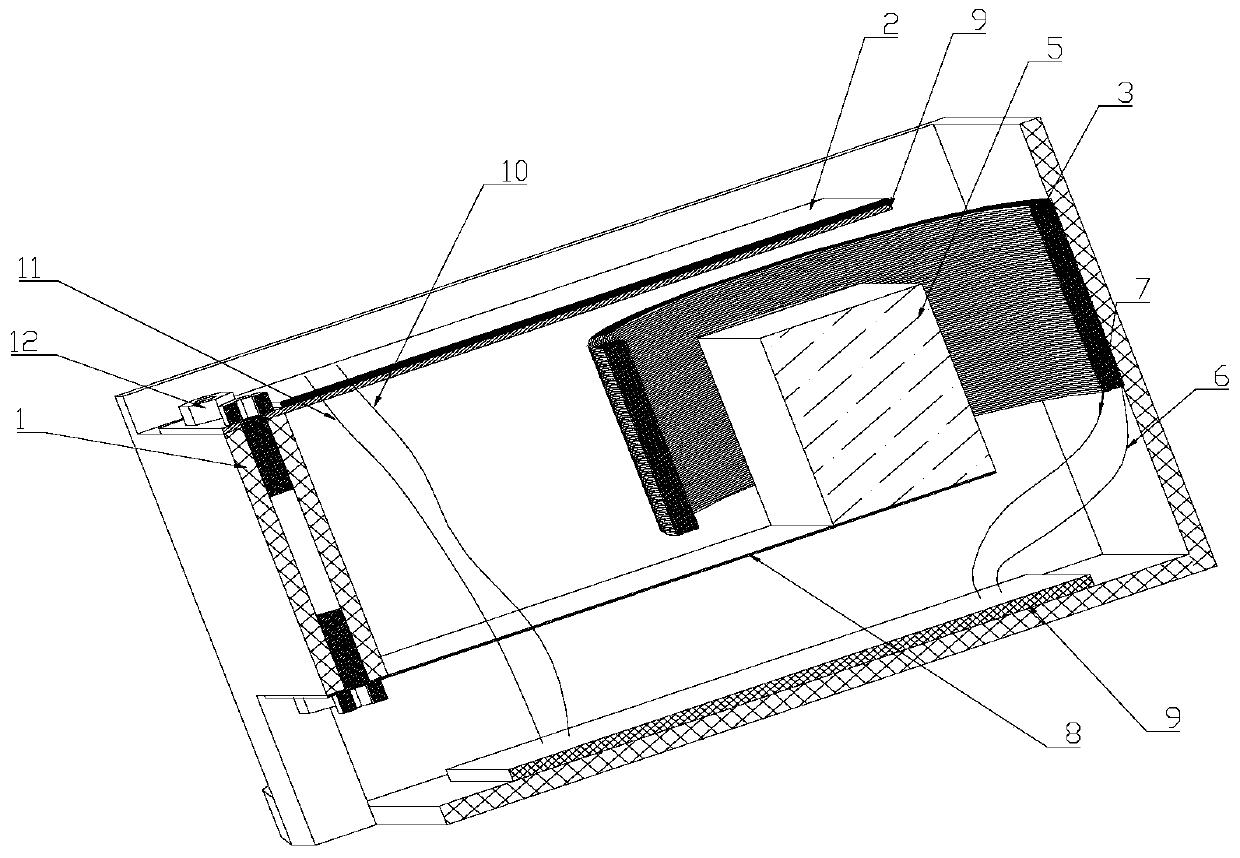

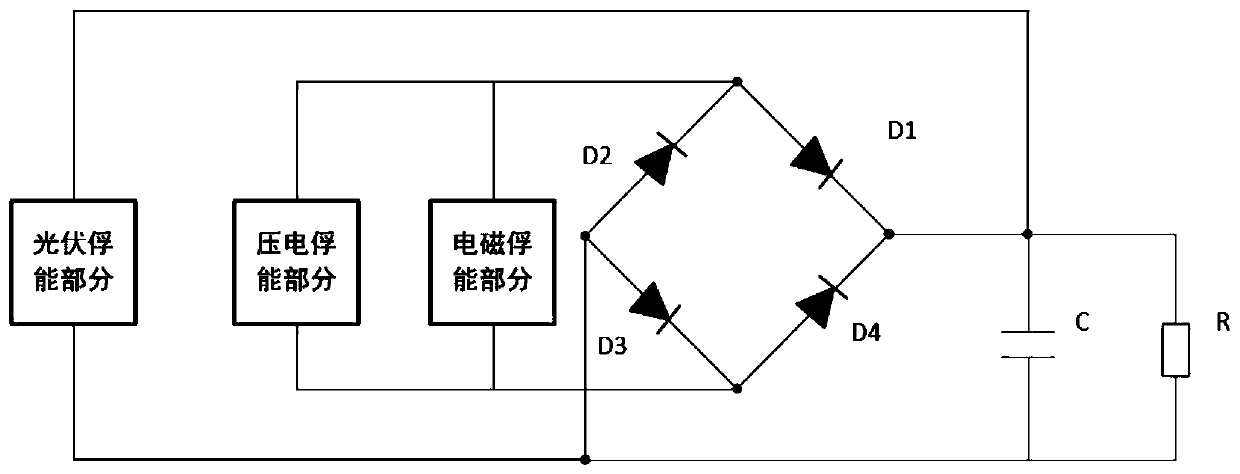

[0042] see figure 1 , The energy harvester provided by this application includes: a housing 1, a photoelectric piezoelectric material 2, a ring coil 3, a high-frequency substrate beam 4, a magnet 5, a coil positive wire 6, a coil negative wire 7, a low-frequency beam 8, and an energy harvesting control circuit 9. The positive lead wire 10 of the photopiezoelectric film, the negative lead wire 11 of the photopiezoelectric film, and the bolt 12.

[0043] In this embodiment, the positive lead wire 10 of the photo-piezoelectric sheet and the negative lead wire 11 of the photo-piezoelectric sheet are positive and negative electrodes that generate current within one vibration cycle. The vibration source is reciprocating vibration, and the generated current is alternating current, and with the change of the vibration direction, the positive and negative poles of the current change.

[0044] The photo-piezoelectric material 2 is attached to the upper surface of the high-frequency mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com