Dual-gas chamber direct-current voltage divider

A technology of DC voltage divider and double air chamber, applied in the direction of voltage divider, etc., can solve problems such as the trouble of inspection personnel, and achieve the effect of improving the accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

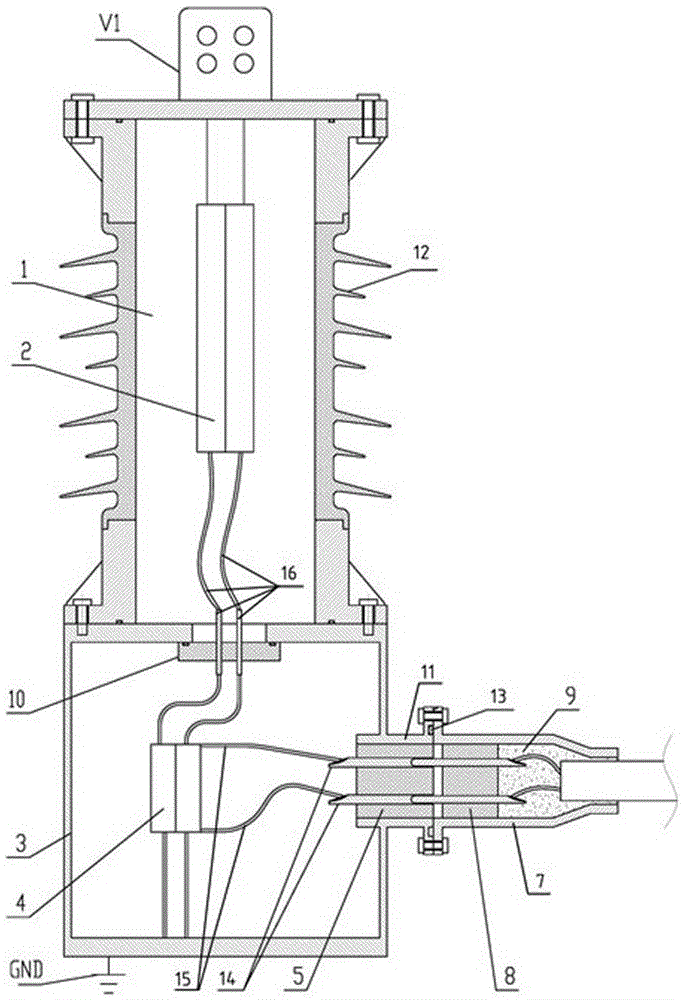

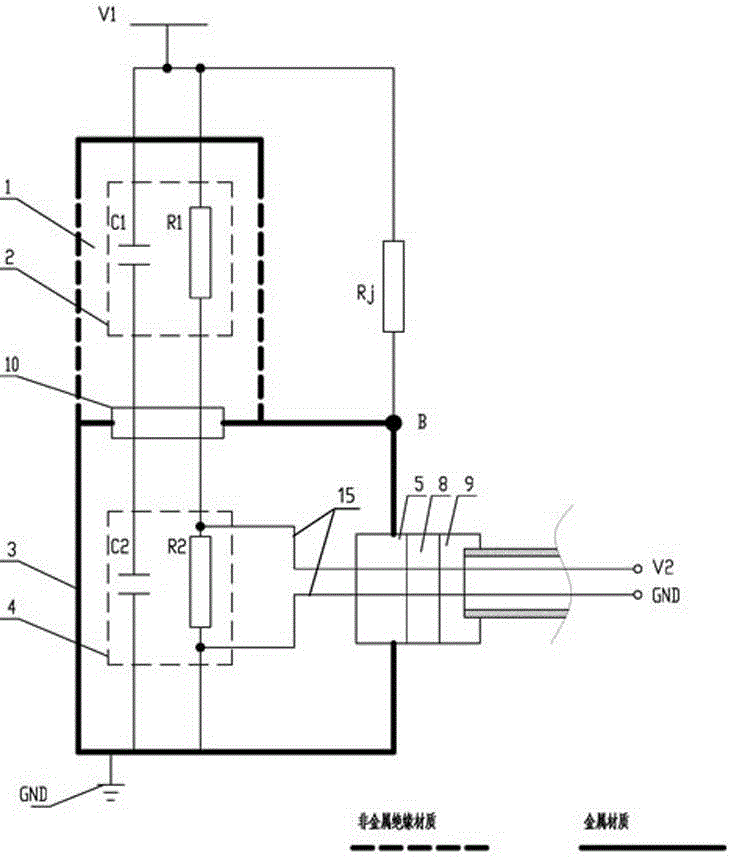

[0017] In order to better describe the DC voltage divider of the present invention, the working principle of the existing DC voltage divider will be described below first.

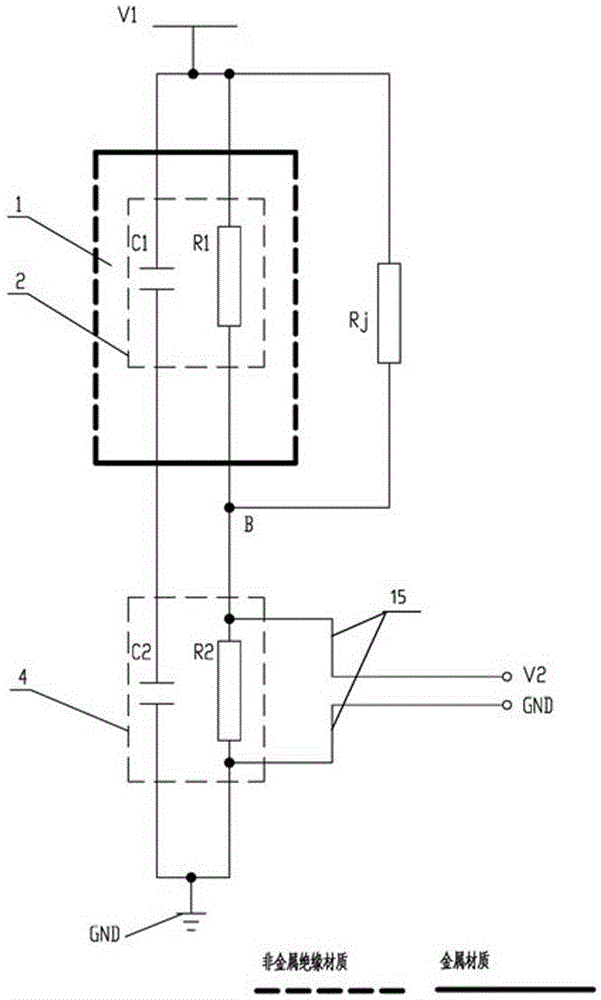

[0018] Through long-term research and a large number of tests on the existing DC voltage divider, it is found that there are stains on the outside of the high-voltage arm housing and the stains contain a lot of water, or in rainy weather, or when the moisture in the outside atmosphere condenses In the case of exposure, etc., the insulating section of the high-voltage arm housing cannot play a good insulating role. Such as figure 1 As shown, the outside of the voltage divider, specifically the surface of the insulating material from V1 to B, will generate a parasitic resistance Rj in parallel with the high-voltage arm, and Rj will be incorporated into the high-voltage arm 2 of the voltage divider through point B, and the transformation ratio of the DC voltage divider On the becomes This will directly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com