Piglet feed emulsifier

A piglet feed and emulsifier technology, applied in feed, food science, application and other directions, can solve the problems affecting the efficiency and effect of piglet feeding or teaching trough, labor efficiency, poor palatability, etc., to reduce piglet stress and labor. Intensity, the effect of improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

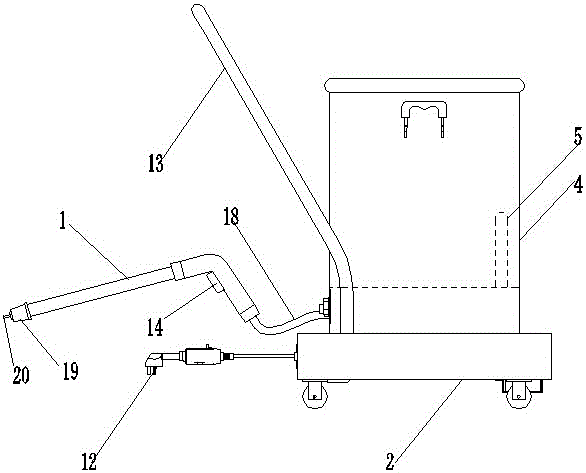

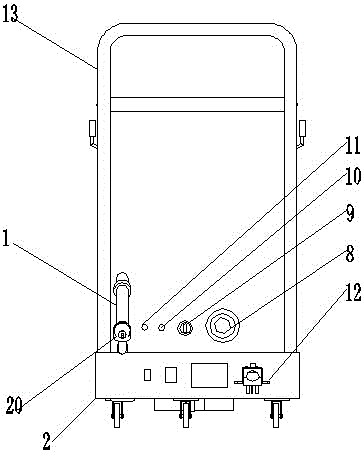

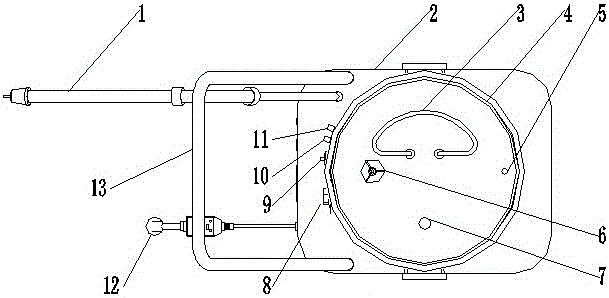

[0015] The present invention is described in further detail in conjunction with accompanying drawing, described agitating device comprises agitating wheel 6 and the motor 16 that is fixed on the bottom of bucket 4, and the output shaft of motor 16 that is connected with the bottom of bucket rotatably seals through the bottom of bucket 4 and stirs The wheel 6 is fixedly connected; the heating device is an electric heating rod 3 fixedly connected to the bottom of the material tank 4; the stirring wheel 6 and the electric heating rod 3 are all arranged in the material tank; the bottom of the material tank is connected with a discharge pipe 18, and the material is discharged The discharge port of the pipe 18 is connected with a discharge valve 19; The electric heating rod 3 can be replaced with an electric heating plate.

[0016] In a further preferred embodiment, a temperature control device is added on the basis of the above-mentioned embodiments, and the temperature control dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com