Electromagnetic control delay booster electric pressure cooker

A technology of boosting voltage and electromagnetic control, applied in pressure cookers, kitchen utensils, household utensils, etc., can solve problems such as poor cooking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

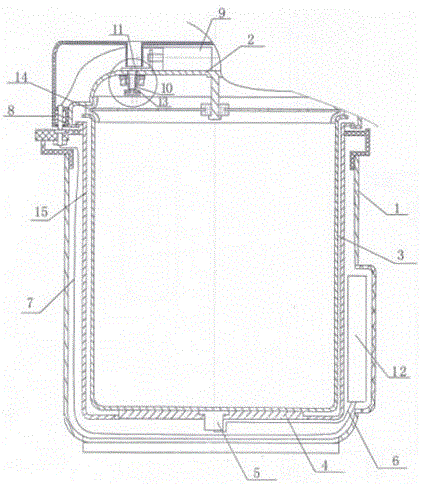

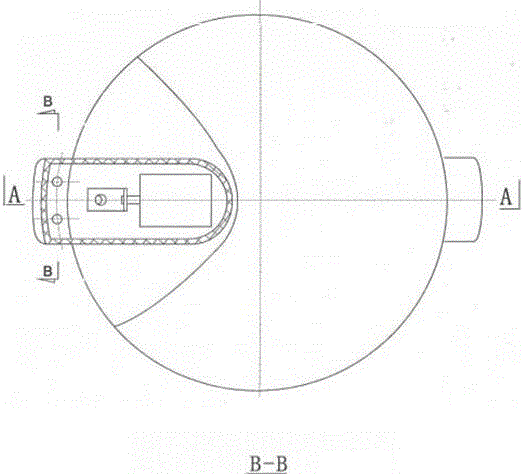

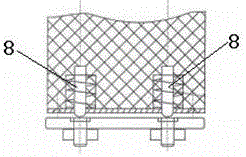

[0035] Such as figure 1 , 2 , 3, and 4, the pot cover 2 and the pot body 1 adopt a split structure, that is, when the pot cover 2 and the pot body 1 are rotated to the open position, the pot cover 2 will be completely separated from the pot body 1; 1 and the closed position of the pot cover 2 are provided with a spring contact connection mechanism, which ensures that the line control mechanism 12 and the input cable of the electromagnet 9 are in the connected state at the closed position of the pot body 1 and the pot cover 2; The contact connection mechanism includes two fixed contacts fixed on the side of the pot body 1, and two movable contacts 8 pushed out by spring force are arranged at the corresponding positions of the pot cover 2, and when the pot body 1 and the pot cover 2 are closed, position, the contacts 8 ejected by the spring are respectively connected to the fixed contacts on the side of the pot body 1, and the input cable 7 of the line control mechanism 12 and ...

Embodiment 2

[0037] Such as Figure 5 , 6, 7, 8, and 9, the pot cover 2 and the pot body 1 are a hinged structure hinged with a hinge 20, the pot cover 2 is turned upwards and opened, and a cable connecting the pot cover 2 and the pot body 1 is provided at the hinged position , to ensure that the line control mechanism 12 is connected with the electromagnet 9 through the cable. Figure 5 , 8 , 9 shows the position of the limit float of this embodiment, the float limit block 11 is directly connected to the electromagnet 9, forming a structure that is driven by the electromagnet 9 to slide on the pot cover 2, and the float limit block 11 is provided with a The hole through which the float passes; at the position of the limit float, the bottom of the float stop block 11 blocks the float and restricts the rise of the float to keep the steam in the pot leading to the atmosphere through the float vent hole 10; at the position of releasing the float, the float stop block 11 The hole opened for...

Embodiment 3

[0039] like Figure 10 , 11 , 12, 13, and 14, the float stop block 11 is connected with the pot cover 2 to form a sliding structure, and the float stop block 11 has a hole for the float to pass through; The ejection slide 16 of the two working positions, the ejection slide 16 is connected with the float stopper 11, so that when the ejection slide 16 moves to the position of ejection and recovery, the float stopper 11 is driven They are respectively in the position of limit float or release float. The float stopper 11 is provided with a spring force device, and the spring force of the device drives the float stopper 11 to always be pressed against the ejection and return ejection surfaces of the two working positions of the ejection slide 16 . The spring force device comprises a guide rod 18 socketed with the float stop block 11, the guide rod 18 is fixed on the pot cover, and a spring 19 is sleeved at the guide rod 18, and the movable end of the spring 19 tops the float stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com