Air cylinder type oil applying oven

A cylinder type, baking oven technology, applied in the direction of baking equipment, kitchen utensils, household utensils, etc., can solve the problems of affecting the grilling effect, reducing efficiency, and pins cannot be rotated, so as to improve the grilling effect and improve the uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

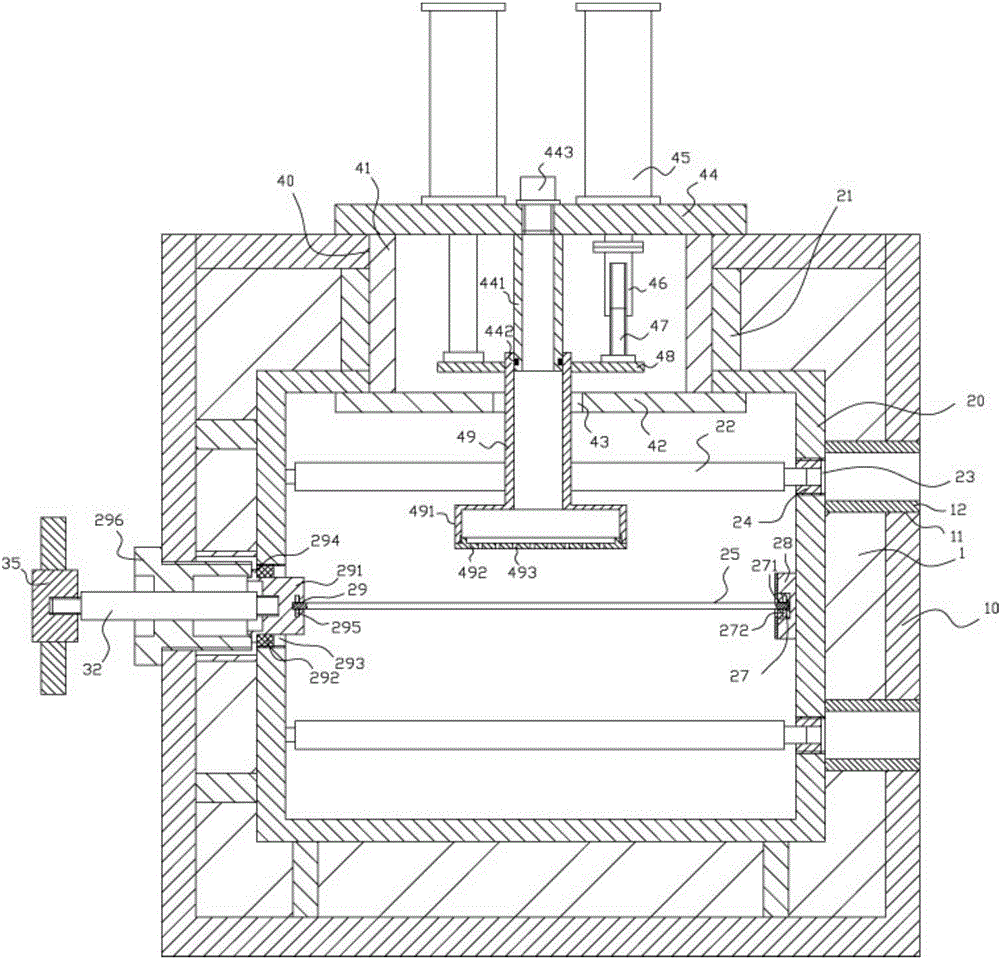

[0022] Example: see Figure 1 to Figure 4 As shown, a cylinder-type oil-coated oven box body includes a box body 10, an inner box body 20 is arranged in the box body 10, and a plurality of connecting plates 21 are fixed on the outer side wall of the inner box body 20, connecting The other end of the plate 21 is fixed on the inner side wall of the box body 10, and the upper and lower parts of the inner box body 20 are provided with a plurality of heating rods 22, and the inner box body 20 between the heating rods 22 of the upper part and the lower part is provided with center pin 25;

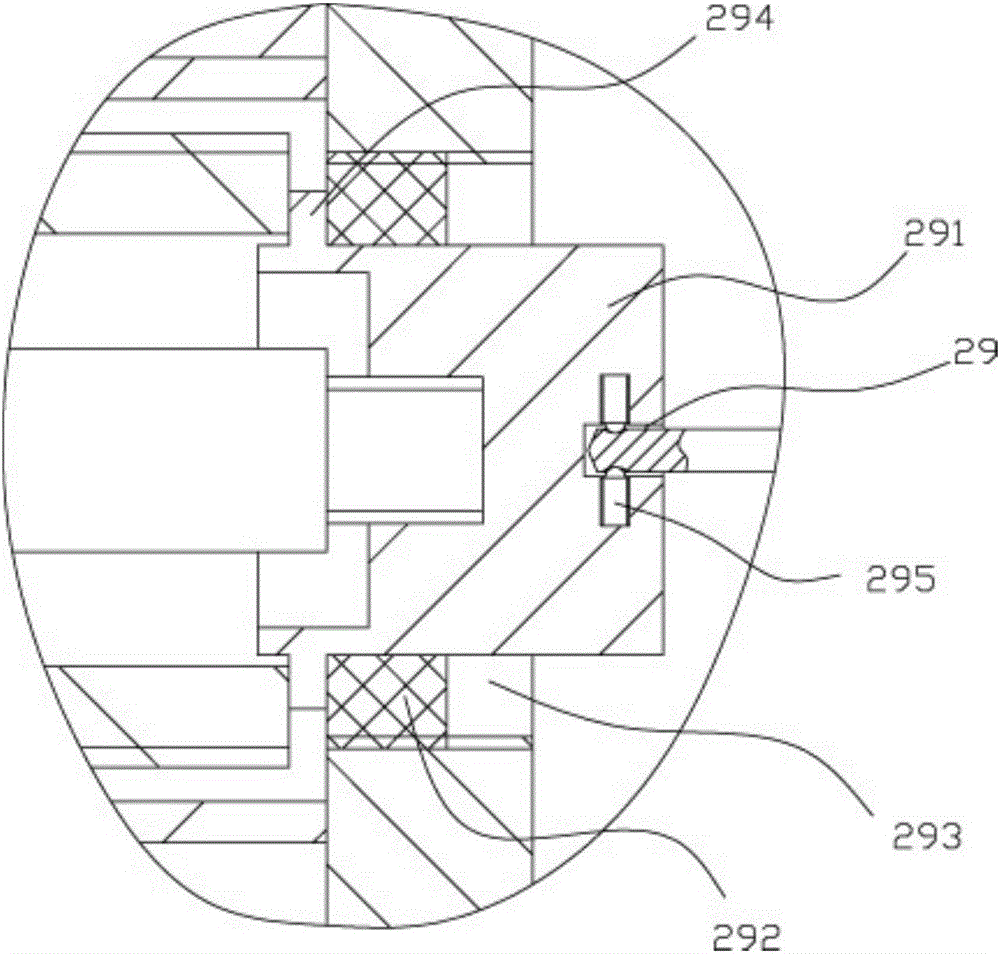

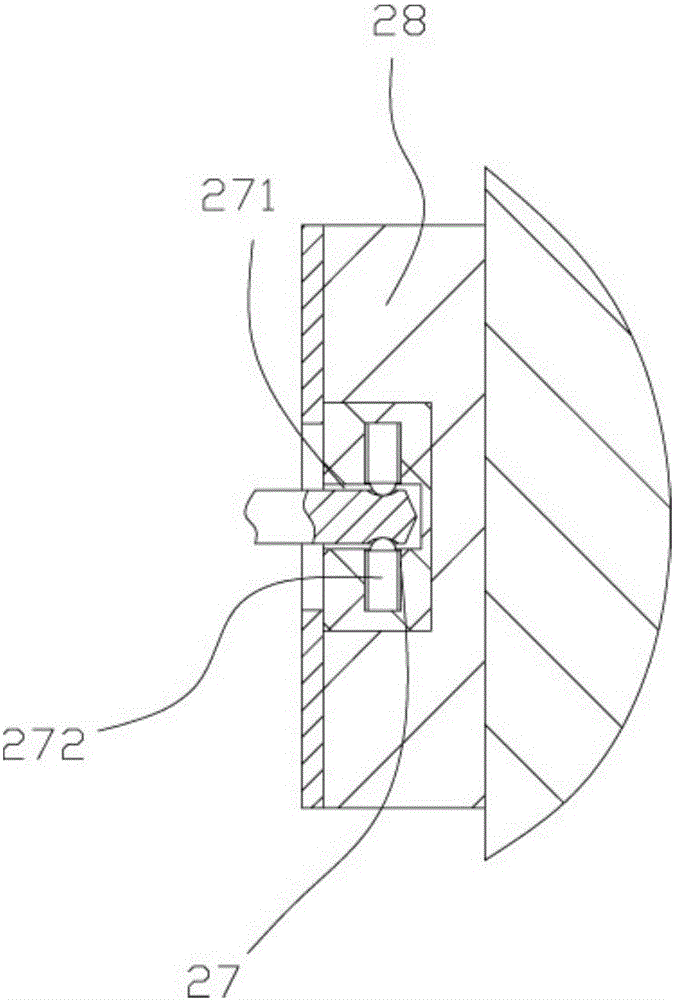

[0023] The right end of center pin 25 is inserted and sleeved in the right socket 271 that is provided in the rotating block 27 that is hinged in the right connecting block 28 that is fixed on the inner side wall of the right side plate of inner box body 20, the inboard of right socket 271 The wall is screwed with a ball plunger 272, and the steel ball of the ball plunger 272 stretches out from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com