Manual lubricating grease filtering device

A filtration device and grease technology, applied in the direction of fixed filter element filter, filtration separation, filtration circuit, etc., can solve the problems affecting the quality, performance and filtration of newly developed products, and achieve safe, economical and reliable use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

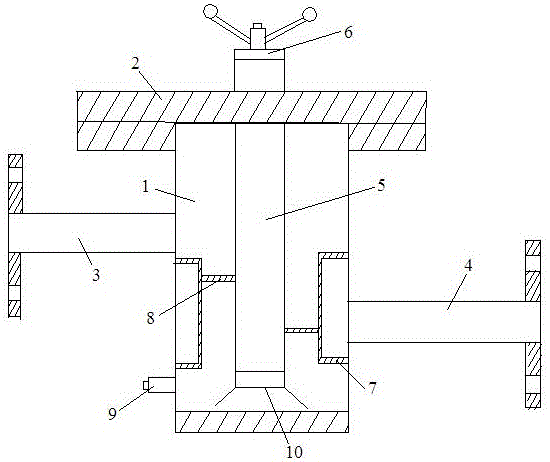

[0009] The specific content of the present invention will be described in detail in conjunction with the accompanying drawings. A manual grease filtering device, comprising a cylindrical cavity 1, a sealing end cap 2 fixed on the upper part of the cylindrical cavity 1, and grease inlets 3 and grease outlets alternately arranged on the side wall of the cylindrical cavity 1 4. The middle part of the cylindrical cavity 1 is provided with a sleeve 5 that penetrates the sealing end cap 2 and is fixedly connected with the sealing end cap 2. The sleeve 5 is provided with a manual screw pusher 6. On the inner wall of the cylindrical cavity 1 The position opposite to the grease outlet 4 is provided with a filter element 7, and the filter element 7 is fixed on the sleeve 5 through the fan-shaped connecting rings 8 arranged staggered up and down. The bottom of the cylindrical cavity 1 is provided with a sewage outlet 9, and the bottom of the sleeve 5 The end is provided with a filter scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com