Automatic pressure relief type single-mode microwave reaction system

A reaction system and single-mode microwave technology, applied in the field of chemical analysis instruments, can solve problems such as inability to directly apply single-mode microwave cavity, high microwave field strength of single-mode cavity, loss of pressure-bearing function, etc., and achieve fast, safe, reliable and efficient digestion process. The effect of ensuring reliability and reducing the risk of bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0096] The present invention will be further described below in conjunction with the drawings.

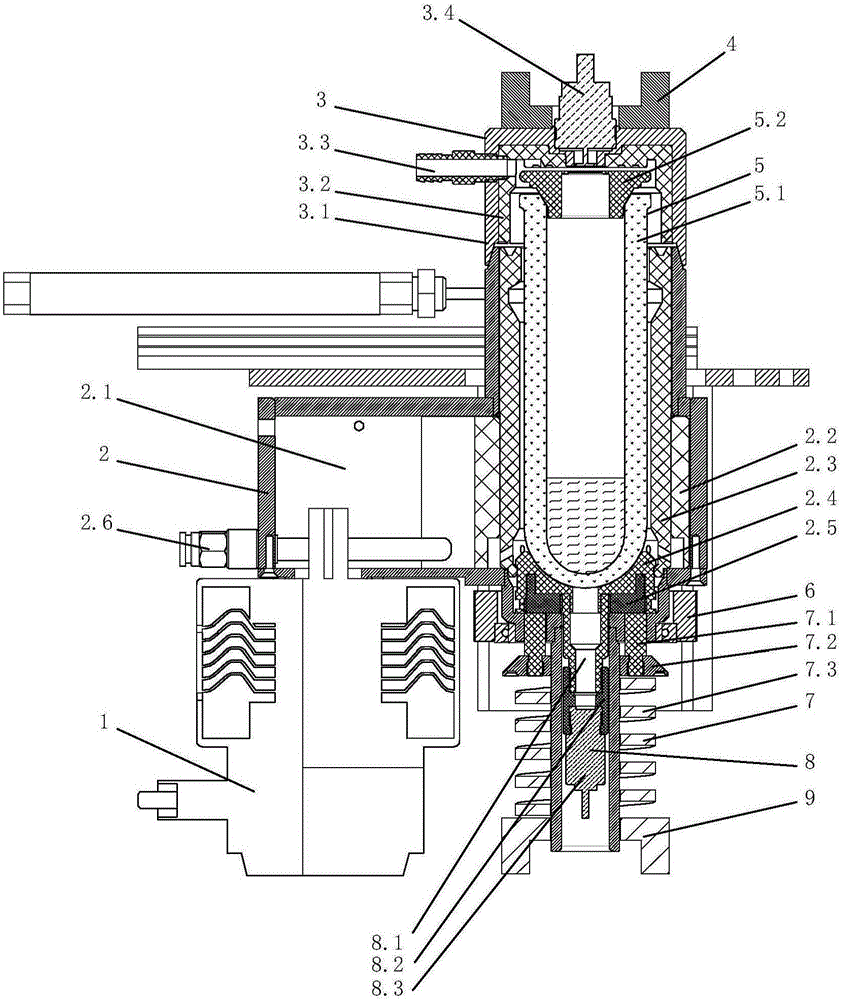

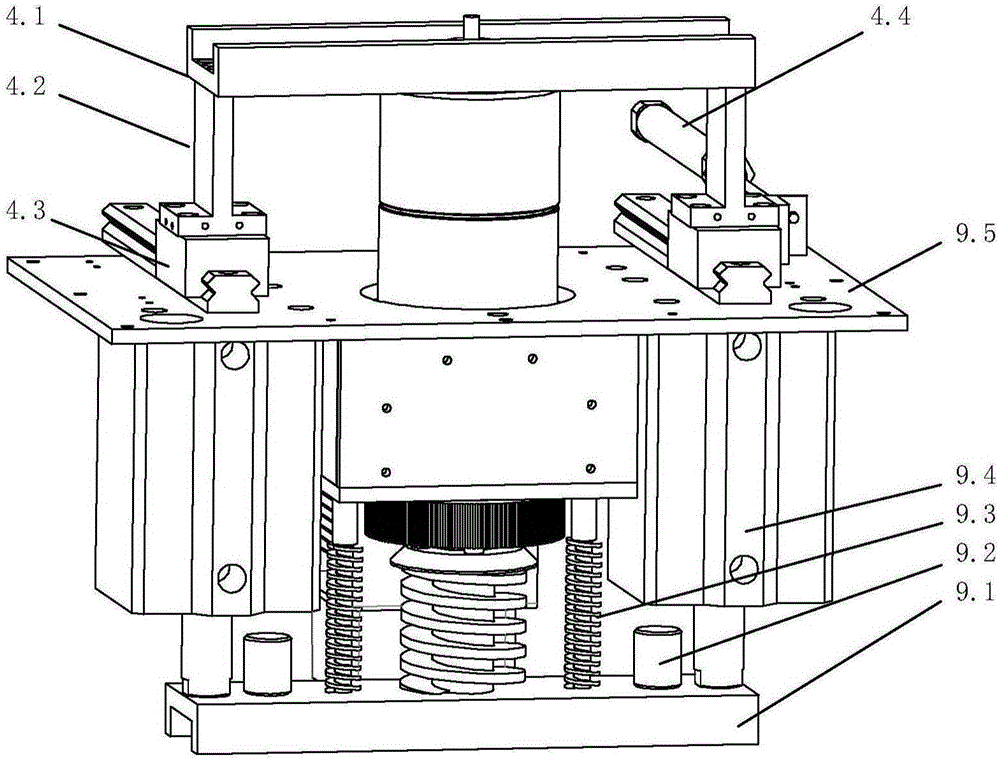

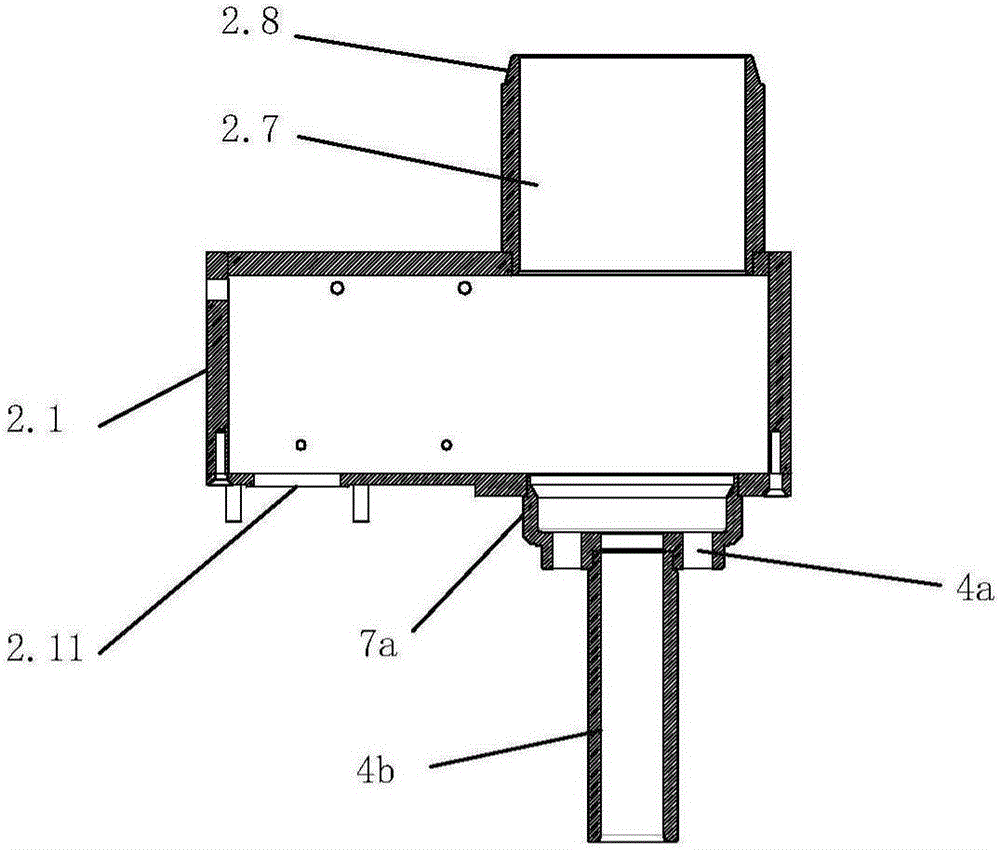

[0097] figure 1 with figure 2 Among them, the technical solution of the present invention provides a self-relief single-mode microwave reaction system, and its invention lies in:

[0098] The self-relief single-mode microwave reaction system consists of a magnetron 1, a single-mode cavity component 2, a single-mode sealing cover component 3, a sealing cover sliding component 4, a test tube component 5, a magnetic stirring component 6, an automatic pressure relief component 7. Infrared temperature measuring component 8 and single-mode cavity lifting component 9 are composed;

[0099] Wherein, in the single mold cavity assembly, a test tube assembly is provided; the test tube assembly includes at least test tube 5.1;

[0100] Above the test tube assembly, a single mold sealing cover assembly and a sealing cover sliding assembly are provided;

[0101] Below the test tube assembly, a magnetic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com