High-efficiency hot rolled steel plate differential leveling and dedusting device

A hot-rolled steel plate, high-efficiency technology, applied in the field of hot-rolled steel plate, can solve the problems of low work efficiency, inconvenient finishing, poor shock absorption effect, etc., and achieve the effect of improving shock absorption effect, improving rust removal effect, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

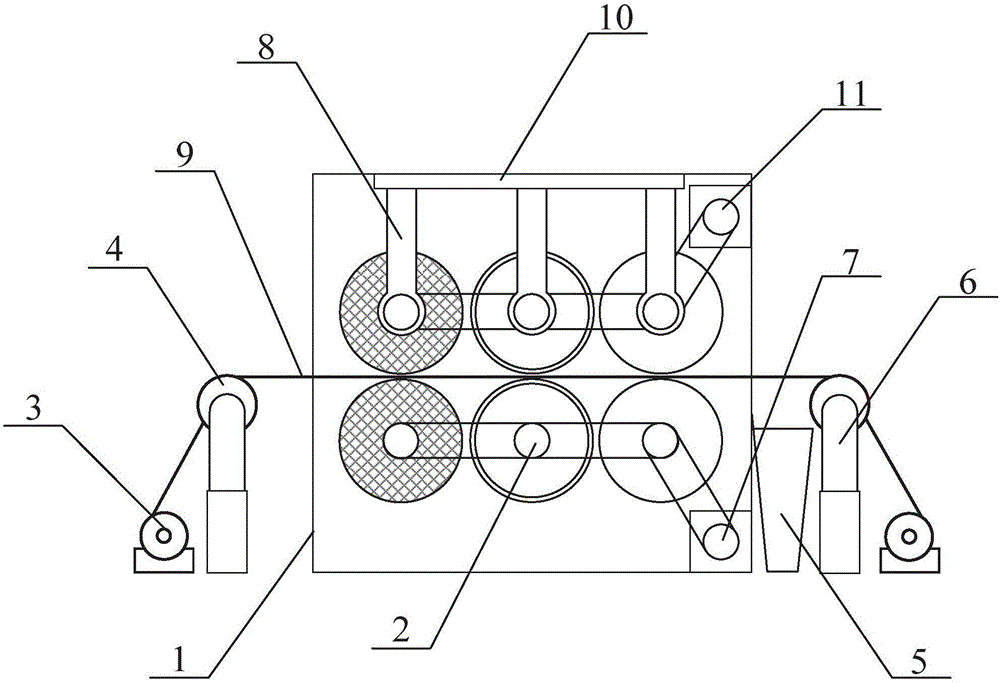

[0020] Such as Figure 1 to Figure 3 shown

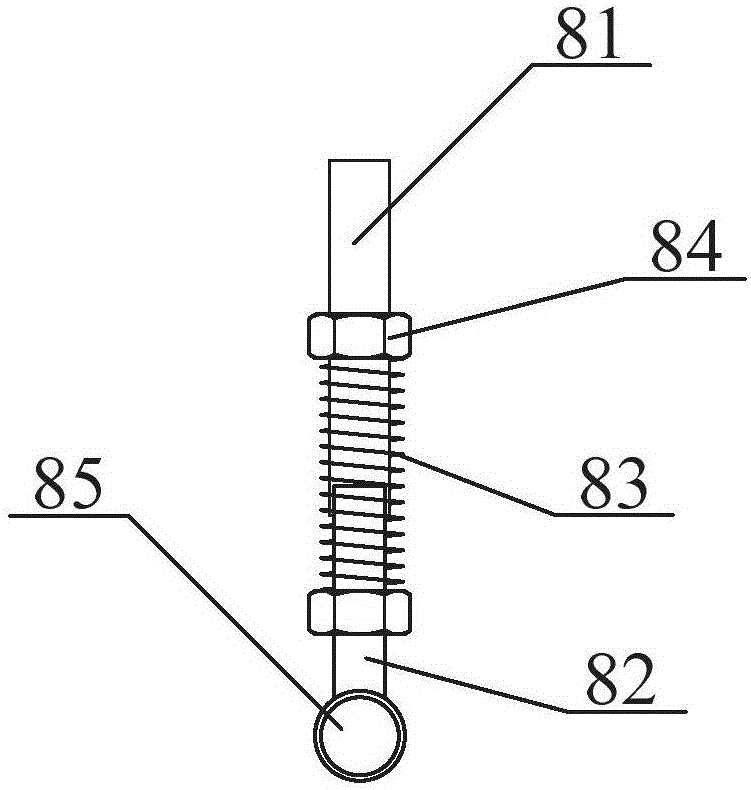

[0021] The technical solution adopted by the present invention to solve the technical problems in the known technology is: a high-efficiency differential smoothing and derusting device for hot-rolled steel plates, including a fixed shell 1, a rolling roller 2, a coiler 3, a guide Roller 4, waste material placement box 5, support frame 6, first motor 7, adjustment pressure bar 8, hot-rolled steel plate 9, fixed plate 10 and second motor 11, described rolling roller 2 is arranged in the interior of fixed shell 1 The fixed plate 10 is fixed on the inner upper side of the fixed shell 1; the adjusting pressure rod 8 is arranged between the fixed plate 10 and the rolling roller 2; the coiler 3 is arranged on the support frame 6 The left and right sides; the guide roller 4 is arranged on the top of the support frame 6; the support frame 6 is arranged on the left and right sides of the fixed shell 1; ; The first motor 7 is mounted on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com