Side plate stamping die for externally-hung heater box shell

A technology of stamping dies and heaters, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of slow forming efficiency and high cost, and achieve the effect of low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

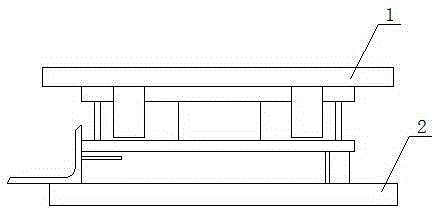

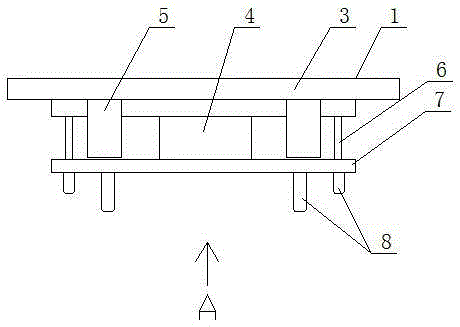

[0013] Such as Figure 1-5 As shown, the stamping die for the side plate of the external heater box includes an upper die 1 and a lower die 2 , and the upper die 1 is arranged above the lower die 2 .

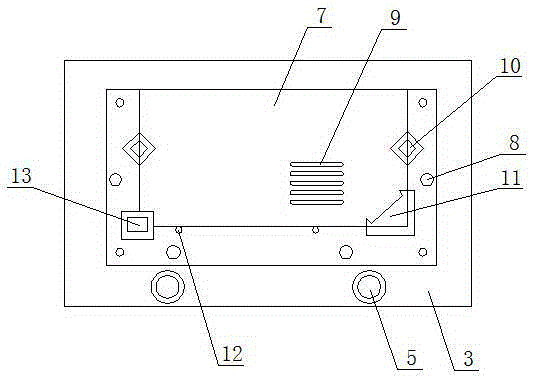

[0014] Upper die 1 comprises upper die base 3, upper die base 3 is provided with upper die base 7, upper die base 7 is connected with upper die base 3 by bolt 6, rubber pad 4 is set between upper die base 7 and upper die base 3, and Five cooling hole punches 9 , one right angle punch 13 , one hypotenuse punch 11 and two V-shaped punches 10 are arranged on the lower surface of the upper template 7 .

[0015] The lower mold 2 includes a lower mold base 14, on which the lower mold base 16 is fixedly connected, and on the upper surface of the lower mold base 16, five heat dissipation hole grooves 20, a right-angle notch 23, a hypotenuse notch 21 and two V Notch 22, cooling hole groove 20 is arranged correspondingly to cooling hole punch 9, right angle notch 23 is arranged correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com