Rivet assembly tool

A technology for assembling tooling and rivets, applied in the field of riveting tooling, can solve the problems of inability to reach into the gap by hand, easy to drop hand-held rivets, inconvenient operation, etc., and achieve the effects of convenient rivet installation, convenient operation and installation, and light and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

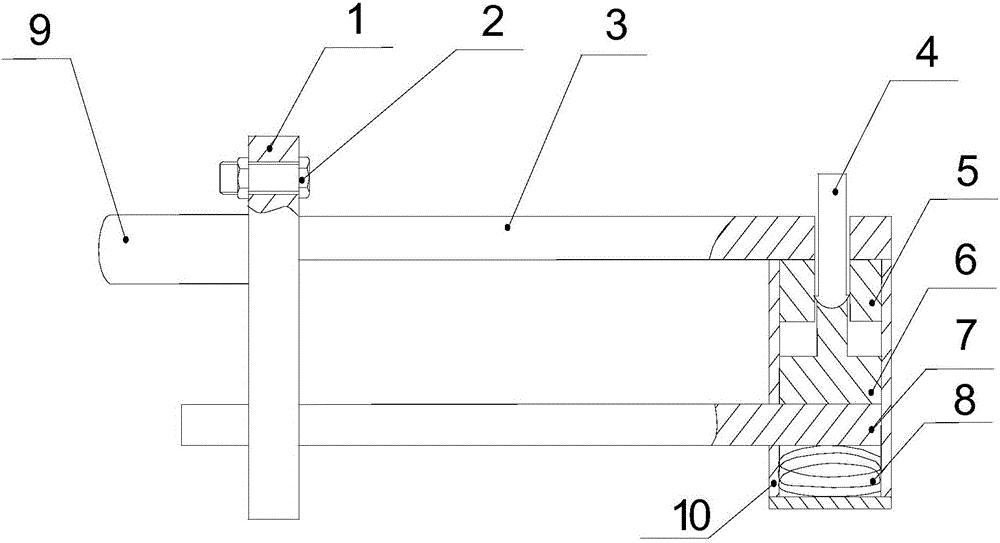

[0007] As shown in the figure, the rivet assembly tooling includes a sleeve 10, a spring 8, a baffle 7, a slider 6, an inner sleeve 5, a pole 3, and a stopper 1. The stopper 1 is fixedly connected to the pole 3, and the stopper 1 The block 1 is provided with a through hole, the baffle plate 7 passes through the through hole and is inserted into the sleeve 10, the spring 8 is arranged in the sleeve 10 and pressed between the baffle plate 7 and the bottom of the sleeve 10, and the slider 6 is arranged on the Inside the sleeve 10 and on the baffle plate 7, the middle part of the slider 6 is provided with an upward boss, the inner sleeve 5 is fixed on the upper part of the sleeve 10, and there is a hole in the middle, and the boss of the slider 6 is located on the inner sleeve 5 In the hole in the middle, and can move up and down, the hole in the middle of the inner sleeve 5 is provided with a rivet 4 to be installed, one end of the rivet 4 is pressed on the boss of the slider 6, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com