Conductor cooing trough device

A technology of cooling water tank and water cooling device, which is applied in the direction of dry gas arrangement, conductor/cable insulation, lighting and heating equipment, etc. It can solve the problems of unsatisfactory cooling effect and simple structure of water tank, and achieve good cooling effect and good cooling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

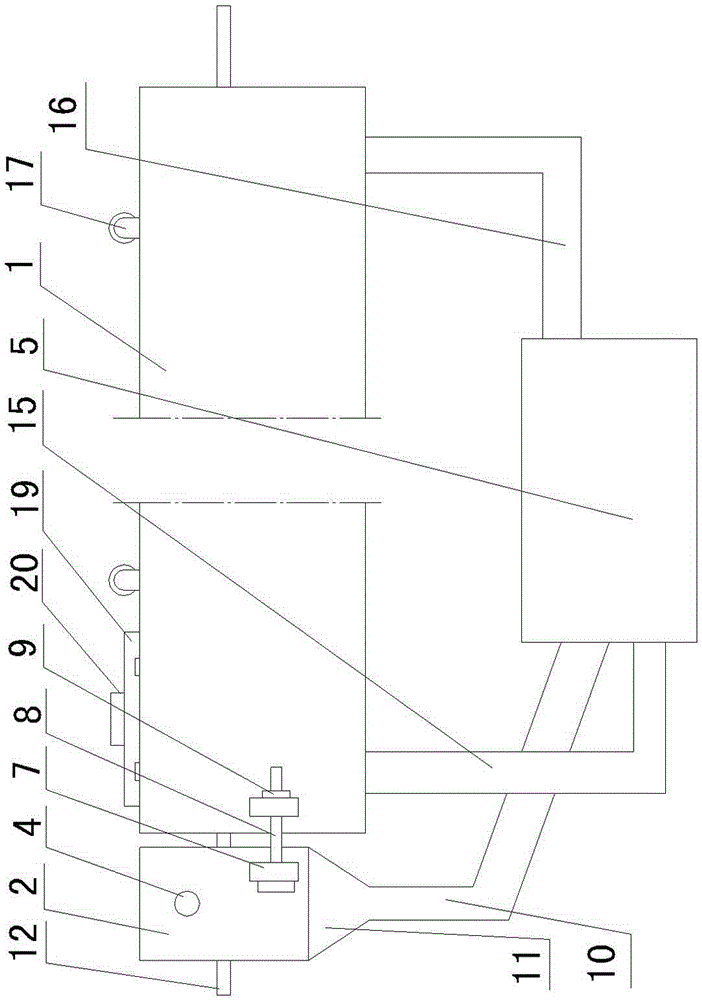

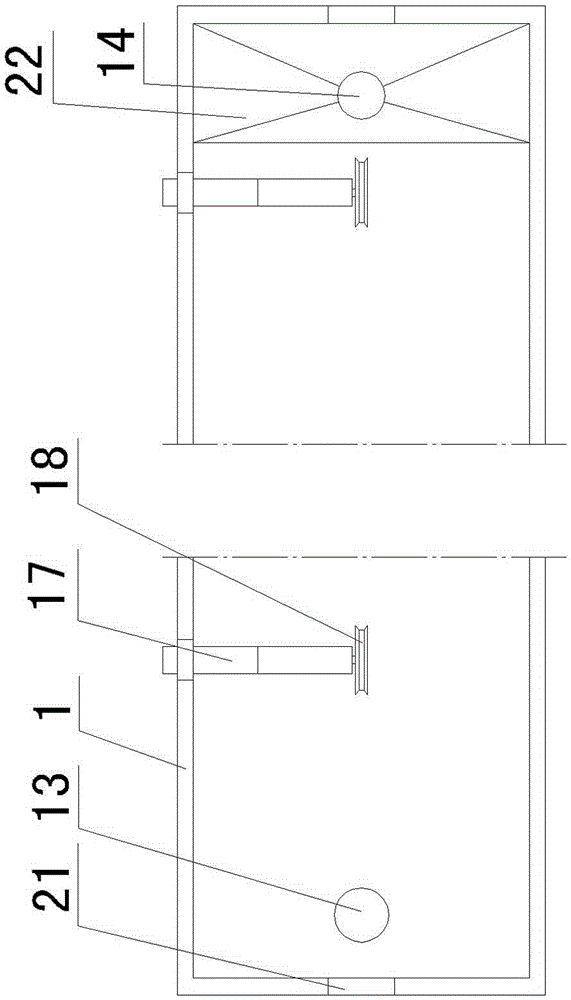

[0018] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a wire cooling water tank device, which includes a water tank 1. The inner bottom of the water tank is a slope, and the slope angle is 10-15°. When the slope angle is too large, the water flow velocity is too large. There is a water outlet 14, the water inlet 13 is connected to the outlet of the water cooling device 5 through the water inlet pipe 15, and the water after the cooling water is sent from the water inlet 13 through the high-pressure pump, and the water outlet 14 is connected to the water cooling device 5 through the water outlet pipe 16 The water cooling device 5 realizes high-temperature water inlet and low-temperature water outlet. U-shaped grooves 21 are opened at both ends of the water tank 1, which is convenient for the wire 12 to pass through and does not contact the water tank 1. Two Z-shaped rods 17 are installed on the side of the water tank 1. One end of the Z-shaped rod 17 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com