Heat treatment mechanism for metallurgical workpieces

A workpiece and box technology, applied in the field of heat treatment mechanism, can solve the problems of uneven cooling, uncontrollable cooling rate, affecting the quality of heat treatment, etc., to achieve the effect of good cooling and control of cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

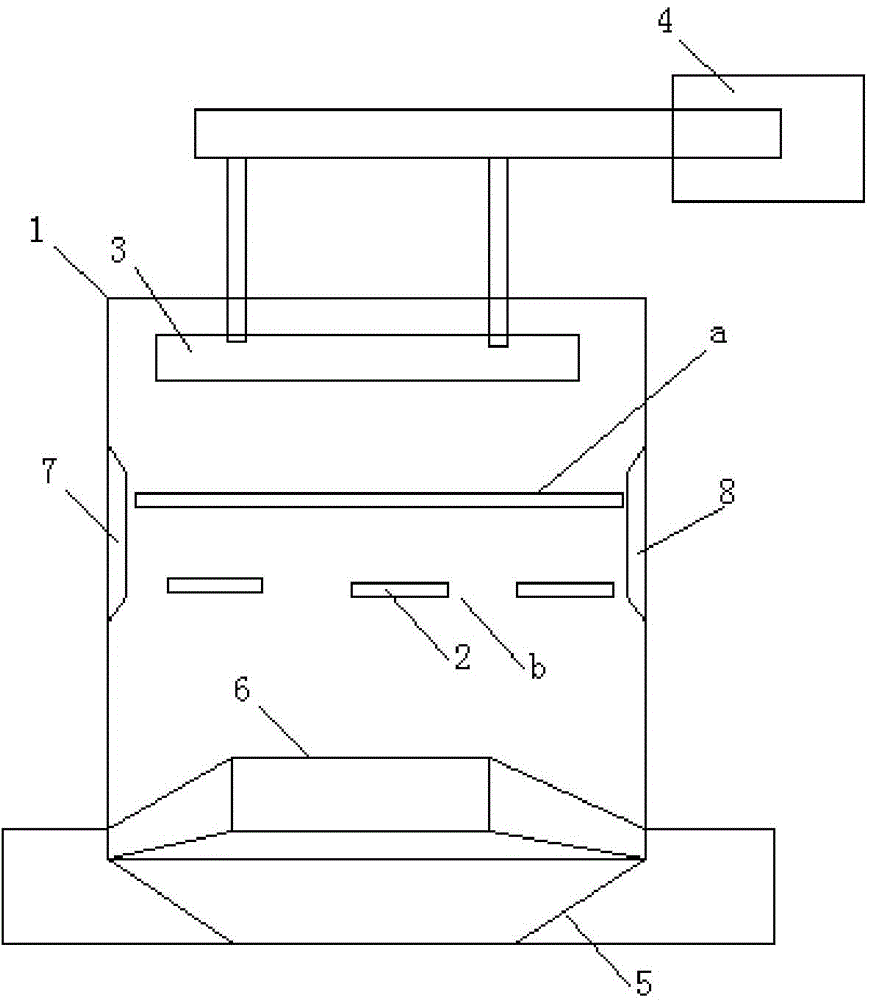

[0009] Such as figure 1 As shown, the heat treatment mechanism for metallurgical workpieces includes a workpiece cooling box 1, and the upper end of the workpiece cooling box 1 is provided with two distribution plate groups a and b, and each distribution plate group includes three distribution plates 2 arranged in parallel. , the two-layer distribution plate group is vertically arranged in space, at least one aerosol generator 3 is arranged on the top of the workpiece cooling box 1, the aerosol generator 3 is connected to the water pump 4, and the bottom of the workpiece cooling box 1 is provided with a water collection tank 5 and The blowing device 6 of upward blowing.

[0010] The inner walls of both sides of the workpiece cooling box 1 are provided with gas circulation components 7 and 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com