Crucible for preparing elemental two-dimensional material and other composite materials

A technology of two-dimensional materials and composite materials, which is applied in the field of new material preparation, can solve the problems of low production efficiency and high production cost, and achieve good cooling, simple structure and good use effect

Inactive Publication Date: 2019-09-10

刘建军

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The graphene prepared by this method has the characteristics of large area and high quality, but at this stage it mainly has the main disadvantages of high production cost and low production efficiency, and the process conditions need to be further improved. The devices of dimensional materials and other composite materi

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

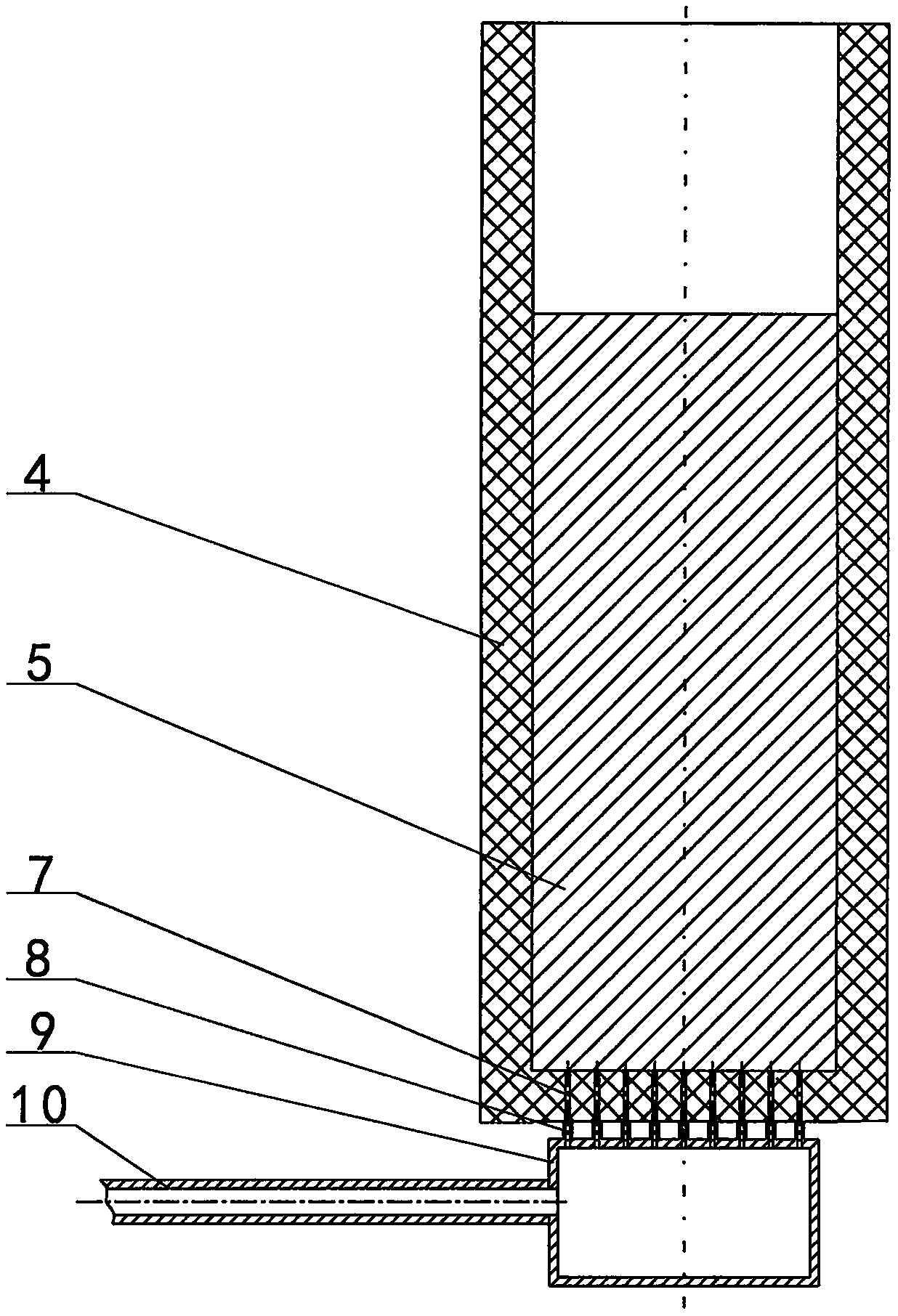

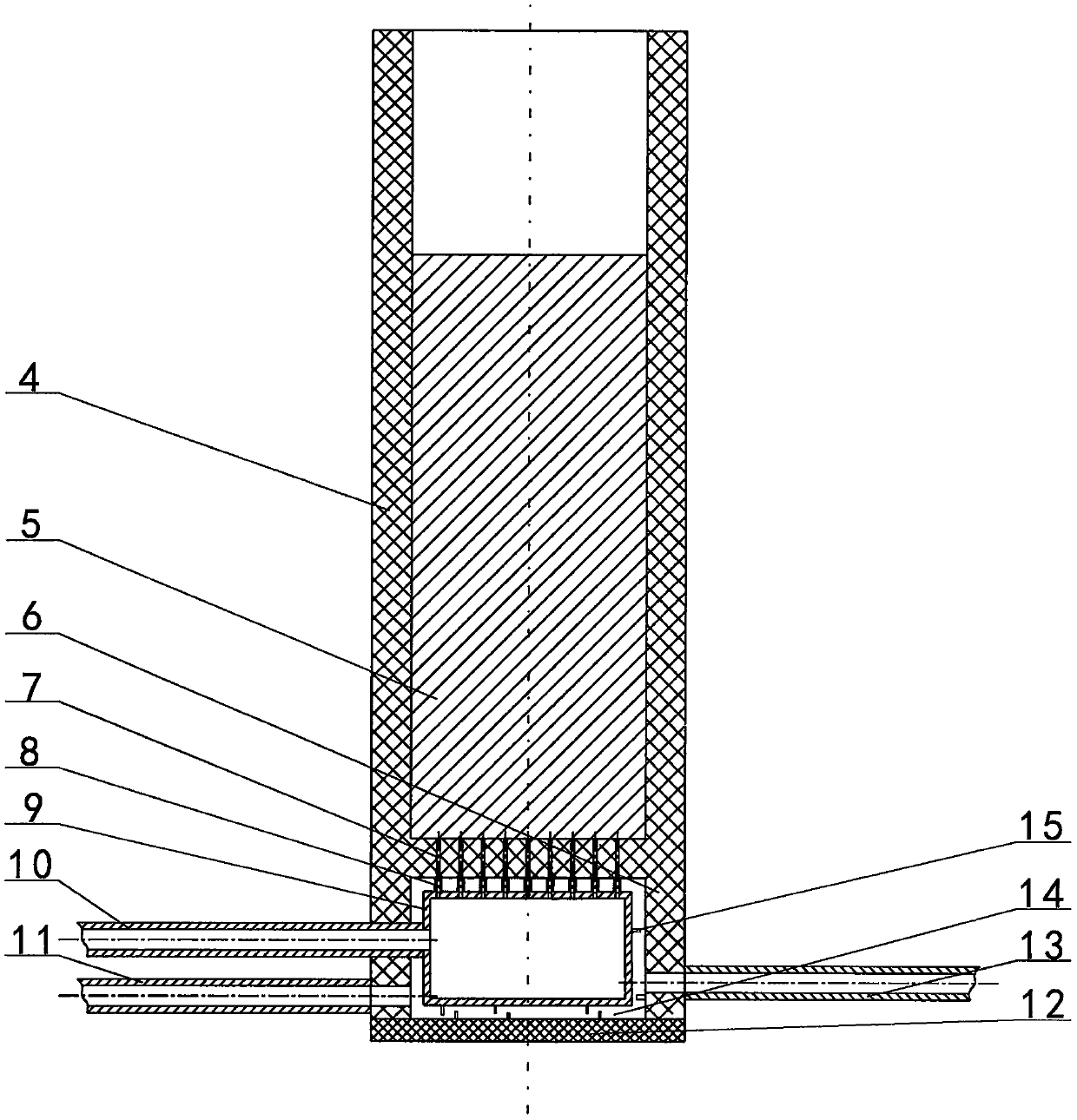

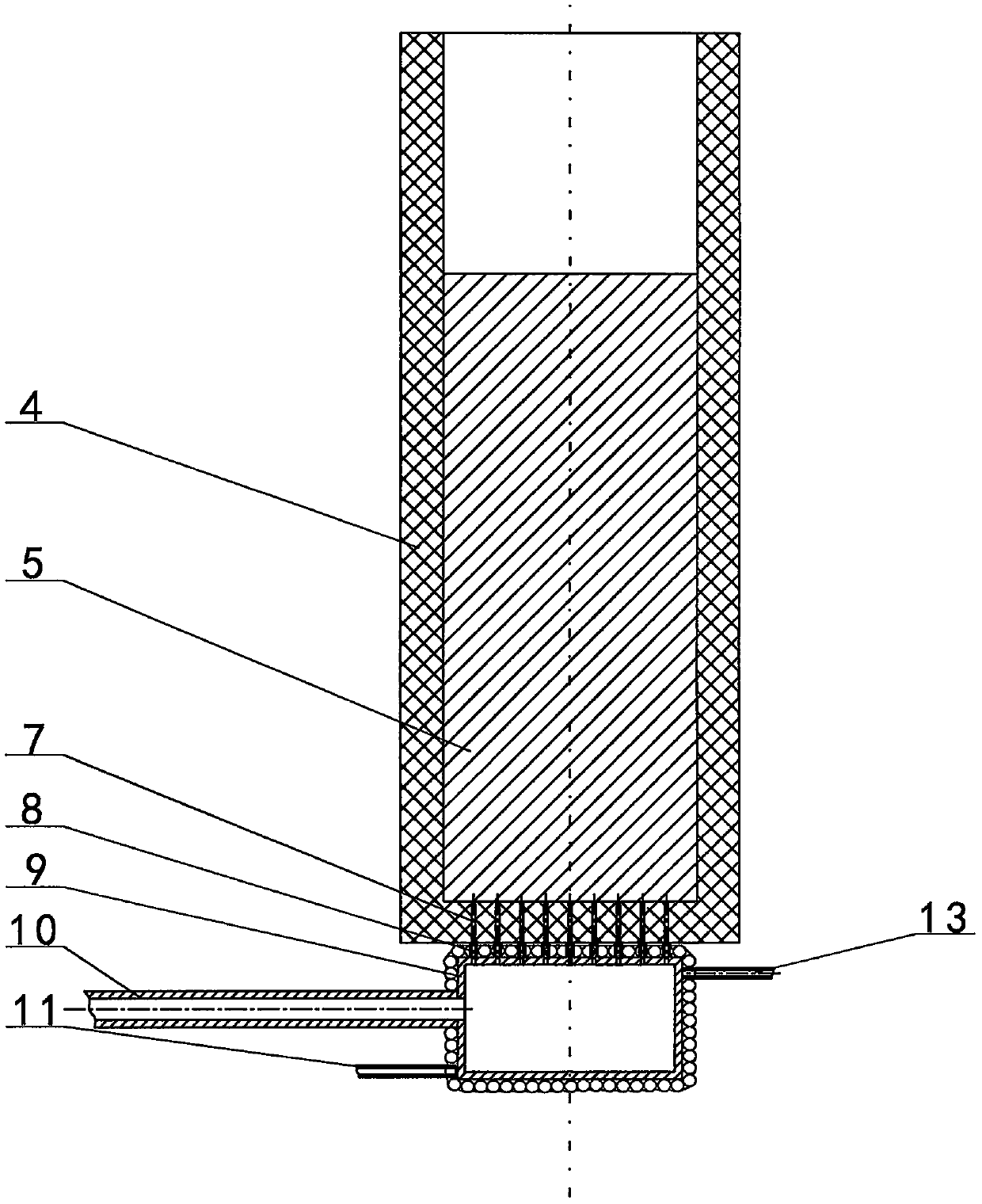

The invention discloses a crucible for preparing an elemental two-dimensional material and other composite materials, and relates to the technical field of new material preparation. The crucible for preparing the elemental two-dimensional material and the other composite materials is characterized in that a gas distribution box (9) is arranged below a crucible body (4), exhaust holes in the gas distribution box are connected with vent holes (7) formed in the bottom of the crucible body, so that the gas distribution box is not in a metal solution, then the situation that gas is cracked in the gas distribution box to generate graphene or other elemental carbon and the like can be effectively prevented, furthermore, the cooling effect is improved, the gas distribution box is arranged in a cooling mechanism, and then cooling gas is introduced into the cooling mechanism to cool the gas distribution box so that the gas distribution box can be better cooled, the situation that the gas is cracked in the gas distribution box to generate the graphene or the other elemental carbon and the like is prevented, meanwhile, the phenomenon that the vent holes are blocked can be further prevented, and the crucible has the characteristics of being simple in structure, good in using effect and the like, and is suitable for wide-range popularization and application.

Description

[0001] 【Technical field】 [0002] The invention relates to the technical field of preparation of new materials, in particular to a crucible for preparing simple two-dimensional materials and other composite materials. [0003] 【Background technique】 [0004] It is known that simple two-dimensional materials and composite materials play a very important role in the development of modern science and technology. The research depth and application breadth of simple two-dimensional materials and composite materials, as well as the speed and scale of production development, have become one of the important symbols to measure the advanced level of a country's science and technology. Since the beginning of the 21st century, the global market for simple two-dimensional materials and composite materials has grown rapidly, especially in Asia, especially in China. Among them, the common composite materials are silicon-coated carbon composite materials, carbon-coated silicon composite mate...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F27B14/10F27D7/02F27D9/00

CPCF27B14/10F27D7/02F27D9/00F27D2009/0005

Inventor 刘建军

Owner 刘建军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com