Manufacturing process of resin frame

A production process and technology of mirror frames, applied in the field of glasses, can solve the problem of inability to adjust the curvature of the mirror frame, and achieve the effect of convenient user operation, enhanced user experience, and convenient and free adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

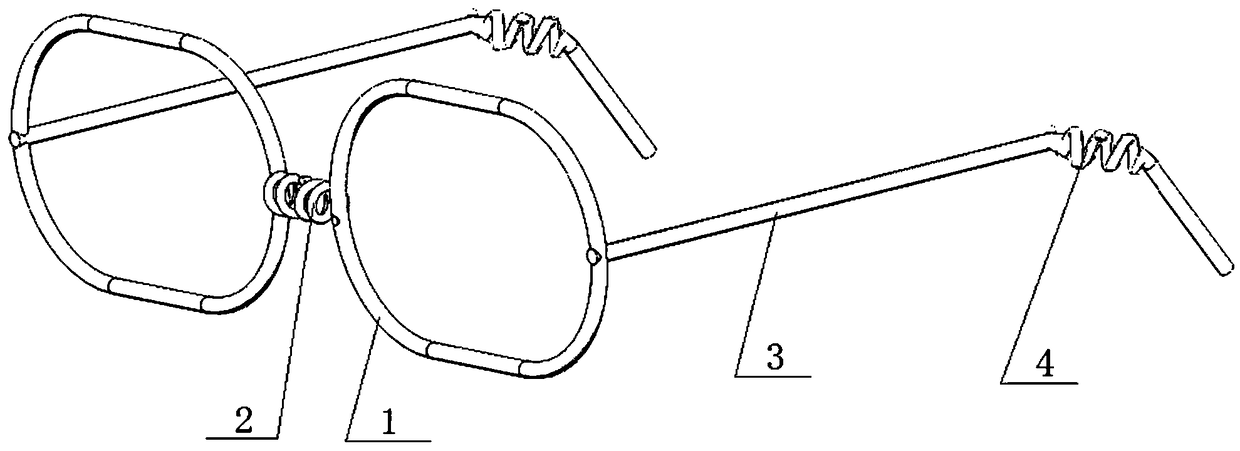

[0036] The manufacturing process of the resin frame, as shown in the figure, includes the following steps:

[0037] 1) Design mold: design a pair of mirror frames and a pair of temples that match the frames;

[0038] 2) Mold making: Make the molds of the set mirror frame and mirror feet;

[0039] 3) Debugging the mold: Repeat the mold adjustment and mold trial after the mold has been made, and then proceed to the next step of installation after reaching the standard;

[0040] 4) Make the keel: make the picture frame keel and the mirror foot keel, the picture frame keel includes two ring frames 1 for placing the lenses and the nose frame 2 connecting the ring frame 1, the mirror foot keel includes the long rod frame 3 and the long rod frame 3 connected The ear frame 4, the ring frame 1 and the long rod frame 3 are all made by bending straight steel wires, and the nose frame 2 and the ear frame 4 are all made of spiral steel wires;

[0041] 5) Install the keel: fix the finishe...

Embodiment 2

[0062] The difference from Example 1 is that part of the outer surface of the mold is wrapped with thermal insulation cotton, and the part where the nose frame 2 and ear frame 4 are installed on the mold is defined as a flexible forming part, and the outer surface of the flexible forming part is exposed, and then the Put the mold into the cooling chamber and cool it at -32°C for 30 minutes, then put the mold at room temperature for 150 minutes, then heat the flexible molding part through the heating spray gun and make the temperature reach 92°C, then put it into the cooling chamber and cool it at -7 Cool at ℃ for 62 minutes, take out the mold and place it at room temperature. After the mold returns to room temperature, open the mold and take out the mirror frame and temples.

Embodiment 3

[0064] The difference from Example 1 is that part of the outer surface of the mold is wrapped with thermal insulation cotton, and the part where the nose frame 2 and ear frame 4 are installed on the mold is defined as a flexible forming part, and the outer surface of the flexible forming part is exposed, and then the Put the mold into the cooling chamber and cool it at -37°C for 25 minutes, then place the mold at room temperature for 150 minutes, then heat the flexible molding part through the heating spray gun and make the temperature reach 92°C, then put it into the cooling chamber and cool it at -7 Cool at ℃ for 62 minutes, take out the mold and place it at room temperature. After the mold returns to room temperature, open the mold and take out the mirror frame and temples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com