Carbon brush end face radian grinding device

A grinding device and radian technology, which is applied in the direction of grinding drive device, grinding/polishing safety device, grinding machine, etc., can solve the problems of low manual grinding efficiency, insufficient grinding, inconvenience, etc., and achieves the reduction of grinding operation difficulty and easy promotion , convenient grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

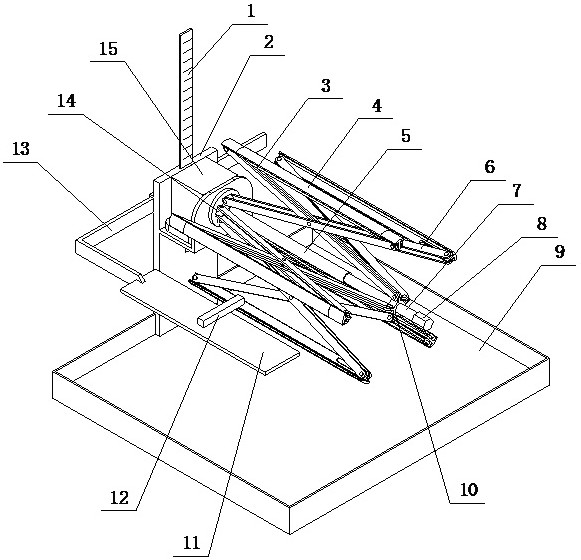

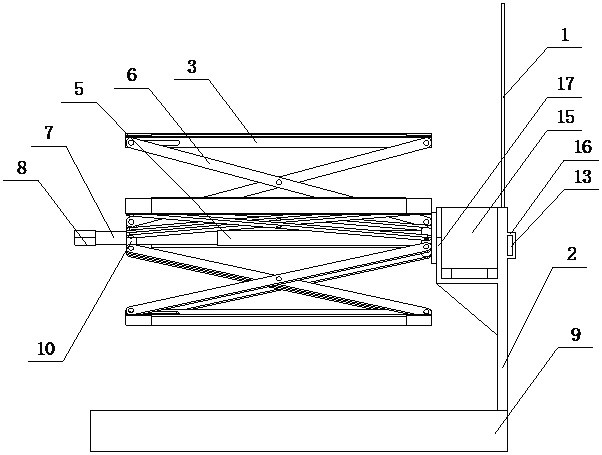

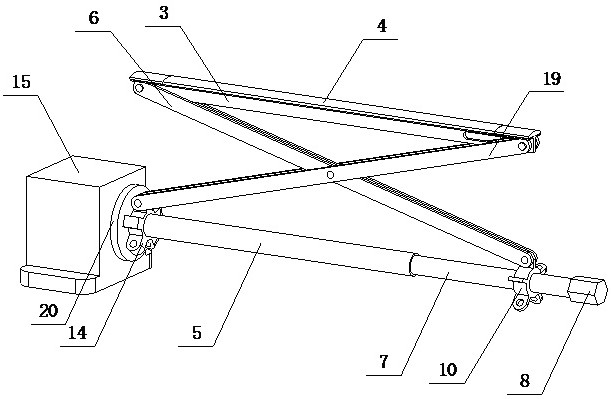

[0019] A carbon brush end face radian grinding device of the present invention is realized in this way. It consists of a support device and a grinding device. The support device consists of a scale (1), a support plate (2), a base (9), a fixed plate (11), a sliding Composed of rod (13) and guide sleeve (16), the support plate (2) is placed on the base (9), the guide sleeve (16) is placed on one side of the support plate (2), and the sliding rod (13) is placed on the guide sleeve (16) Inside, a limit block is placed on one end of the sliding rod (13), the other end of the sliding rod (13) is bent toward the base (9), and the fixing plate (11) is placed on the sliding rod (13) On the other end of the support plate (2), a scale (1) is placed on the top of the support plate (2), and a baffle is placed around the base (9), and the baffle extends obliquely upward to the outside of the base (9) , the grinding device consists of a support T plate (3), a grinding bar (4), a rotating sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com