Arc-shaped ornament board

A decorative panel and arc technology, which is used in building components, covering/lining, construction, etc., can solve the problems of limited radian, poor flexibility and flexibility of decorative panels, cumbersome installation, etc., and achieves good flexibility and flexibility. Good sound absorption and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

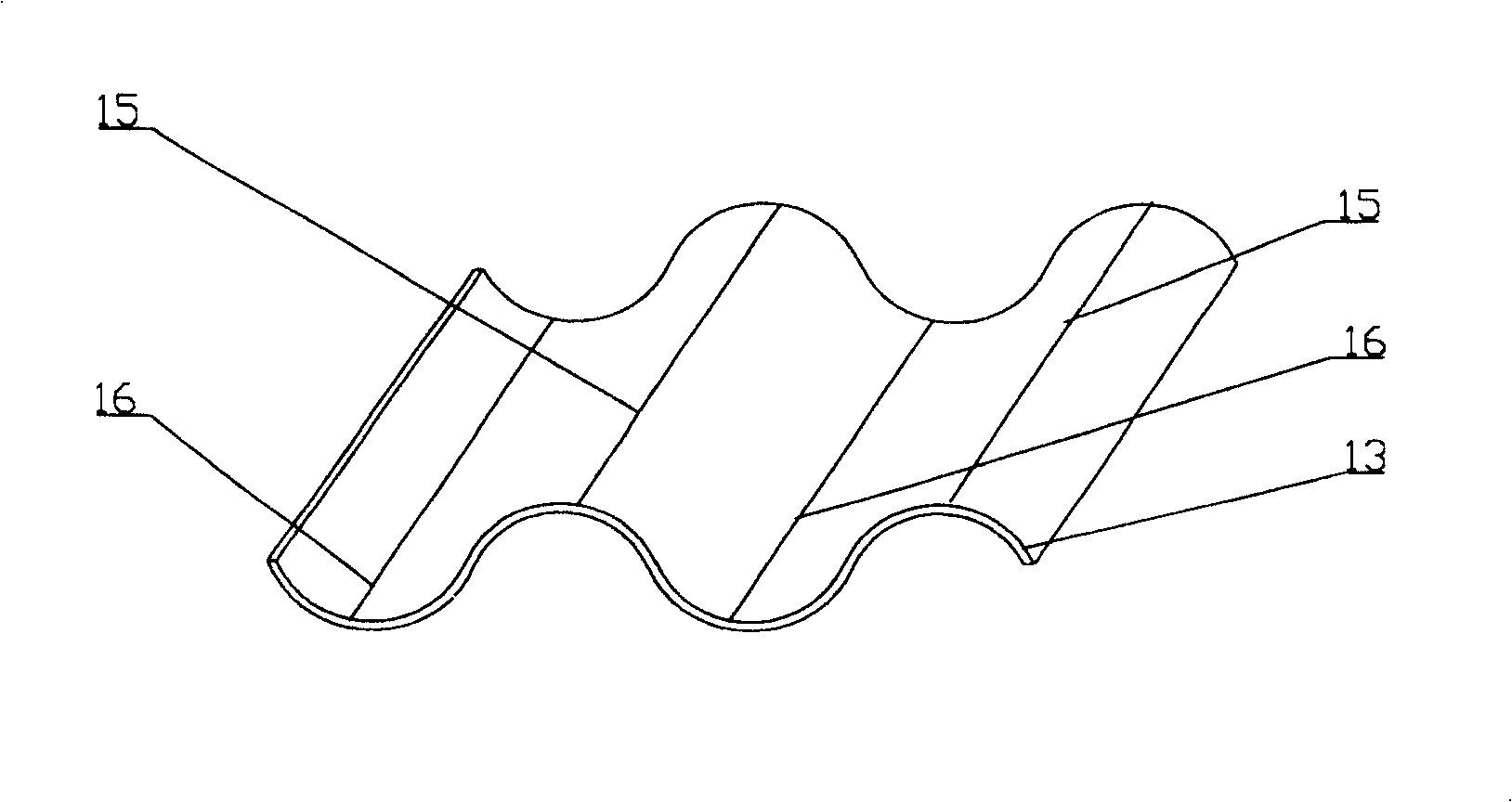

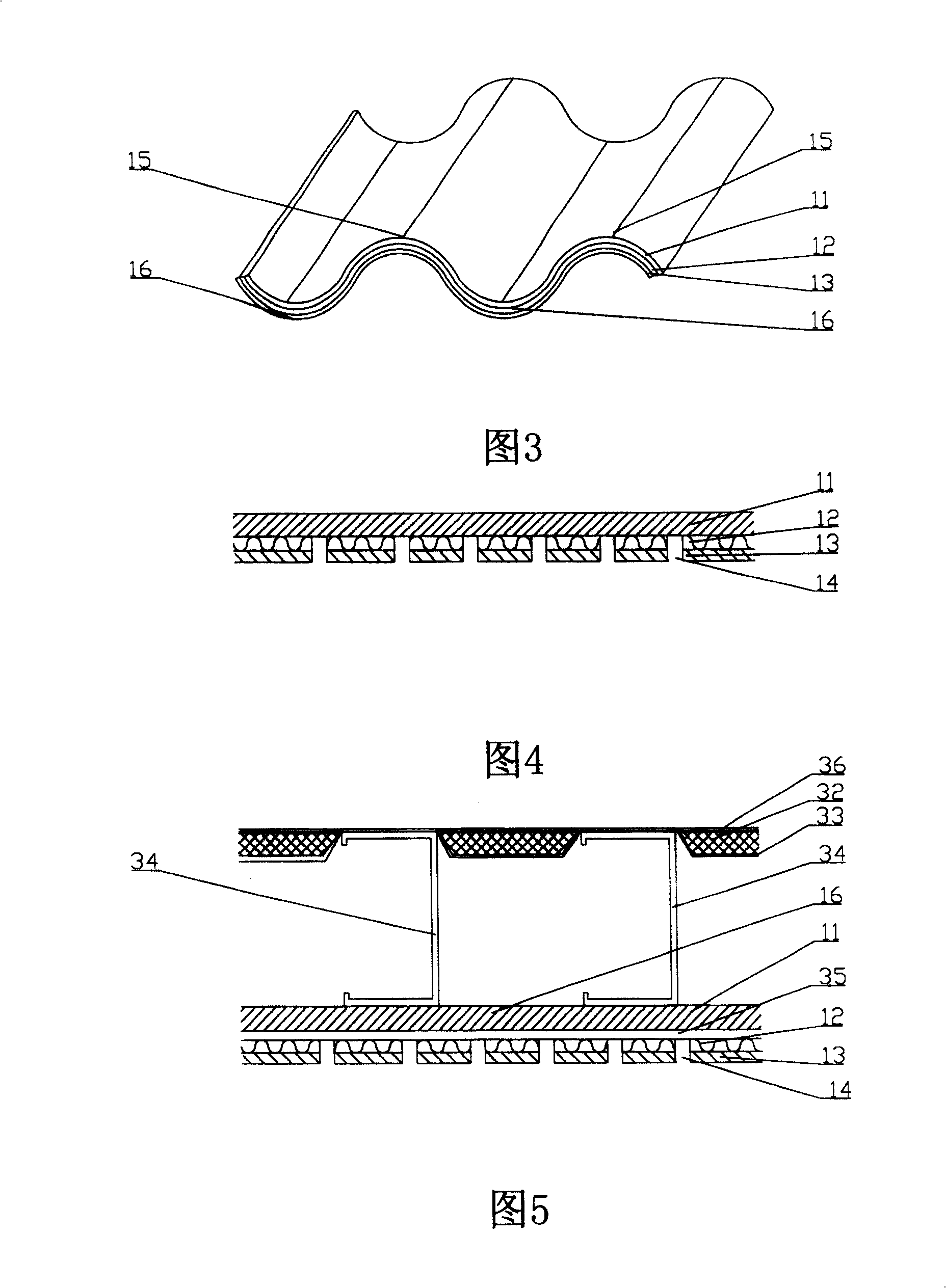

[0021] As shown in FIG. 3 , the aluminum plate 13 of this embodiment is wavy and connected at intervals by a lower arc 16 and an upper arc 15 . The lower arc 16 and the upper arc 15 have the same radius, equal arc length, and opposite opening directions. One side of the aluminum plate 13 is painted, and the other side is laminated with the corrugated sound insulation board 12 of aluminum, and the corrugated sound insulation board 12 is bonded with the sound insulation foam 11 of acrylic acid. The advantage of this embodiment is that the curvature of the decorative board can be easily and freely adjusted, and the heat resistance performance is good. Adding auxiliary thermal insulation material during installation can achieve better thermal resistance. In wet or cold seasons, moisture will not condense on the back of the decking. The corrugated surface diffuses and spreads light evenly, enhancing the brightness of the environment.

Embodiment 2

[0023] As shown in FIG. 4 , the aluminum plate 13 of this embodiment is wave-shaped and connected at intervals by a lower arc 16 and an upper arc 15 . The lower arc 16 and the upper arc 15 have the same radius, equal arc length, and opposite opening directions. One side of the aluminum plate 13 is painted, and the other side is laminated with the corrugated sound insulation board 12 of aluminum, and the corrugated sound insulation board 12 is bonded with the sound insulation foam 11 of acrylic acid. The aluminum plate 13 and the corrugated sound-insulating plate 12 have holes 14 communicating with each other. The holes 14 are evenly distributed. The advantage of this embodiment is that the radian of the decorative board can be easily and freely adjusted, the sound absorption performance is good, and the sound can be well absorbed through the hole 14 and the sound insulation filler 12 . The noise attenuation coefficient under the Japanese standard test can reach 0.93. The cor...

Embodiment 3

[0025] As shown in FIG. 5 , the aluminum plate 13 of this embodiment is wavy and connected at intervals by a lower arc 16 and an upper arc 15 . The lower arc 16 and the upper arc 15 have the same radius, equal arc length, and opposite opening directions. One side of the aluminum plate 13 is a painted surface, and the other side is bonded with the corrugated sound insulation board 12 of aluminum. The aluminum plate 13 and the corrugated sound-insulating plate 12 have holes 14 communicating with each other. The holes 14 are evenly distributed. The other side of the corrugated sound insulation board 12 is covered with a 50 micron polyethylene water vapor barrier layer 35 , and the other side of the water vapor barrier layer 35 is covered with acrylic sound insulation foam 11 . The soundproof foam 11 is pressed with an aluminum inlay 34 , the inlay 34 is concave with one side open, and the inlay 34 bears against the supporting net 33 at the same time. The opening of the inlay 34...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com