How to use a rolling machine

A rolling machine and pressure technology, applied in the direction of presses, presses using rotating pressure components, manufacturing tools, etc., to achieve stable and reliable work, good pressing effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

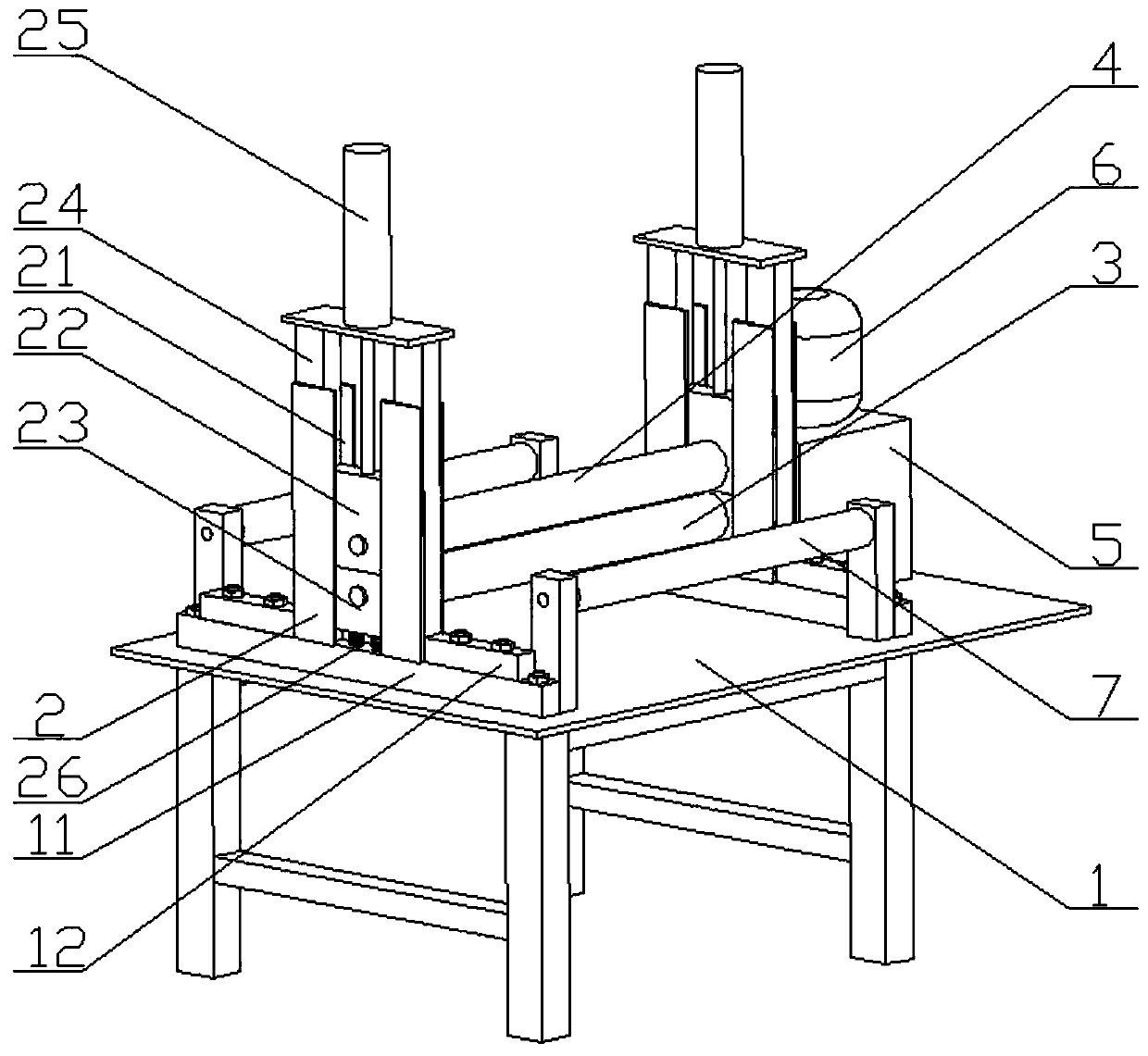

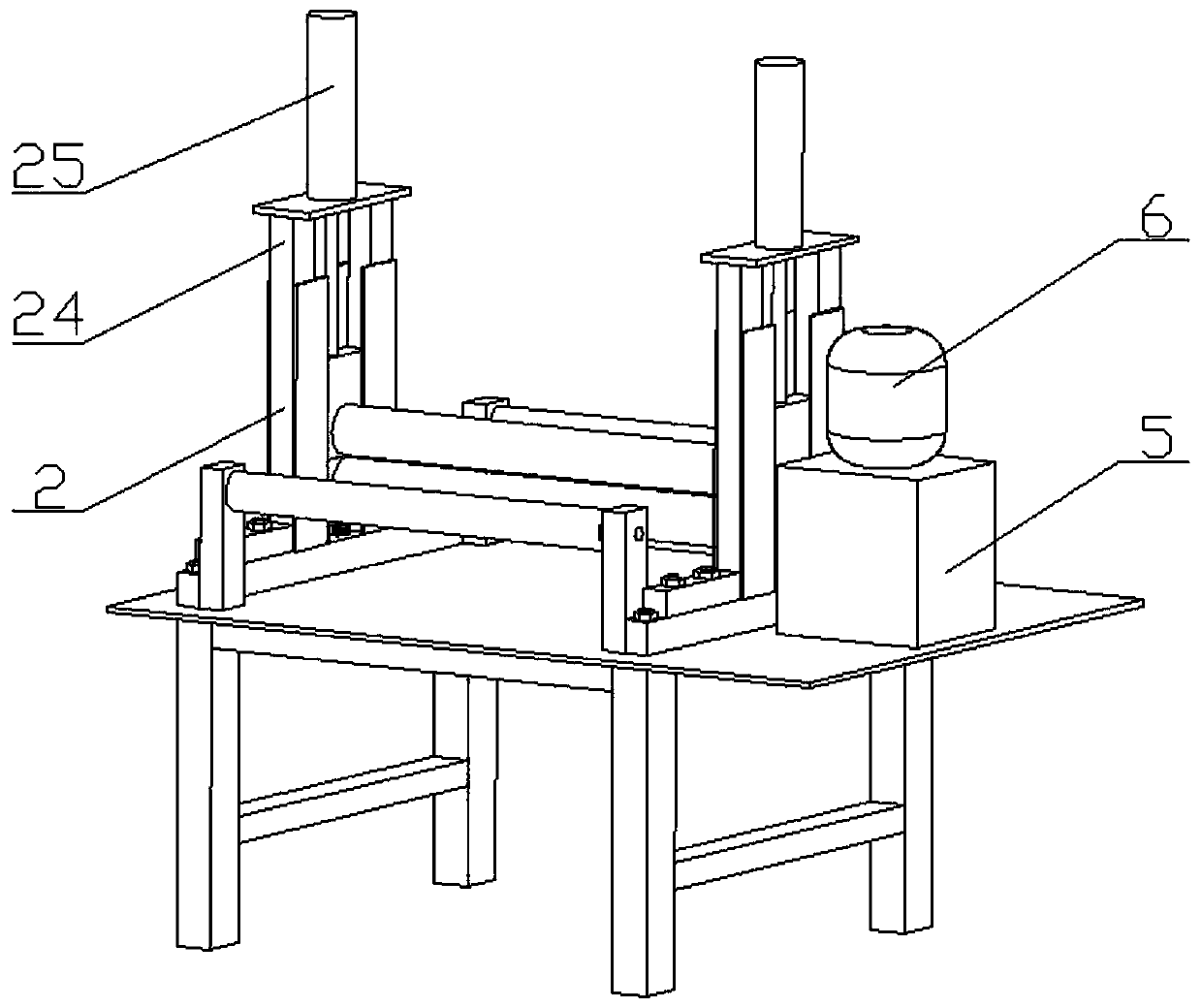

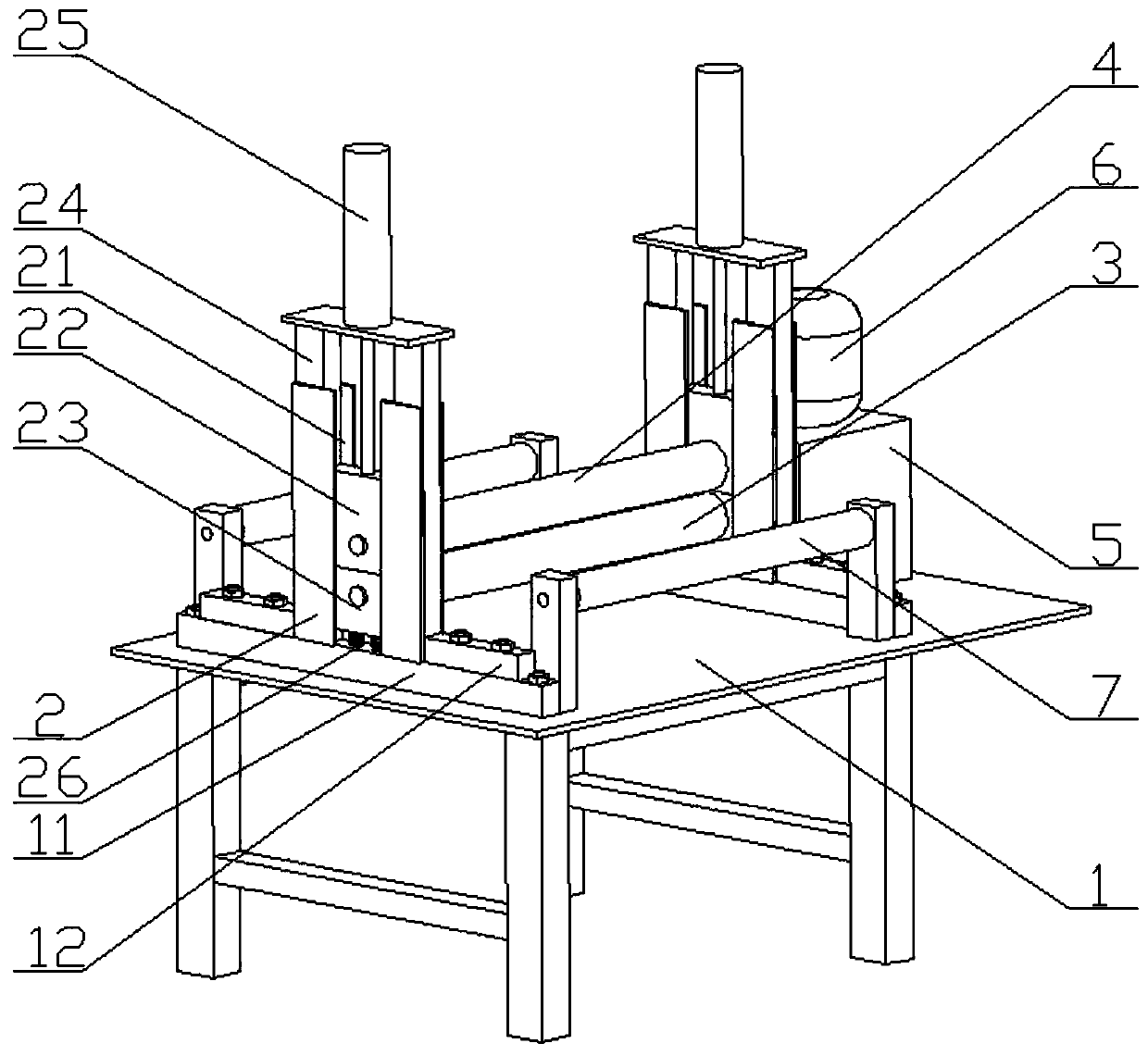

[0039] Such as figure 1 and figure 2 As shown, a rolling machine includes a base 1, a pressure roller, a carrier roller 7, a reducer 5 and a motor 6, and the bottom of the base 1 is provided with four support legs; the upper part of the base 1 is fixed on both sides A load-bearing base 11 is provided; a column 2 is fixedly arranged on each of the two load-bearing bases 11; a reinforcing block 12 is fixedly installed on the two sides of the load-bearing base 11 and the column 2; the column 2 includes Two opposite single columns; one side of the opposite side of the two single columns is provided with a chute 21, the upper end of the column 2 is provided with a cylinder support 24, and the cylinder support 24 is fixedly provided with a cylinder 25;

[0040] Described pressing roll comprises lower roller 3 and upper roller 4; Described lower roller 3 two ends are respectively provided with lower roller seat 23, and lower roller 3 can rotate on lower roller seat 23, and describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com