Glass bottle mould

A glass bottle and mold technology, used in glass blowing molds, glass blowing, glass forming, etc., can solve problems such as slow cooling of glass liquid and stress in glass bottles, improve flatness, prevent stress concentration, and speed up Effects of the forming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

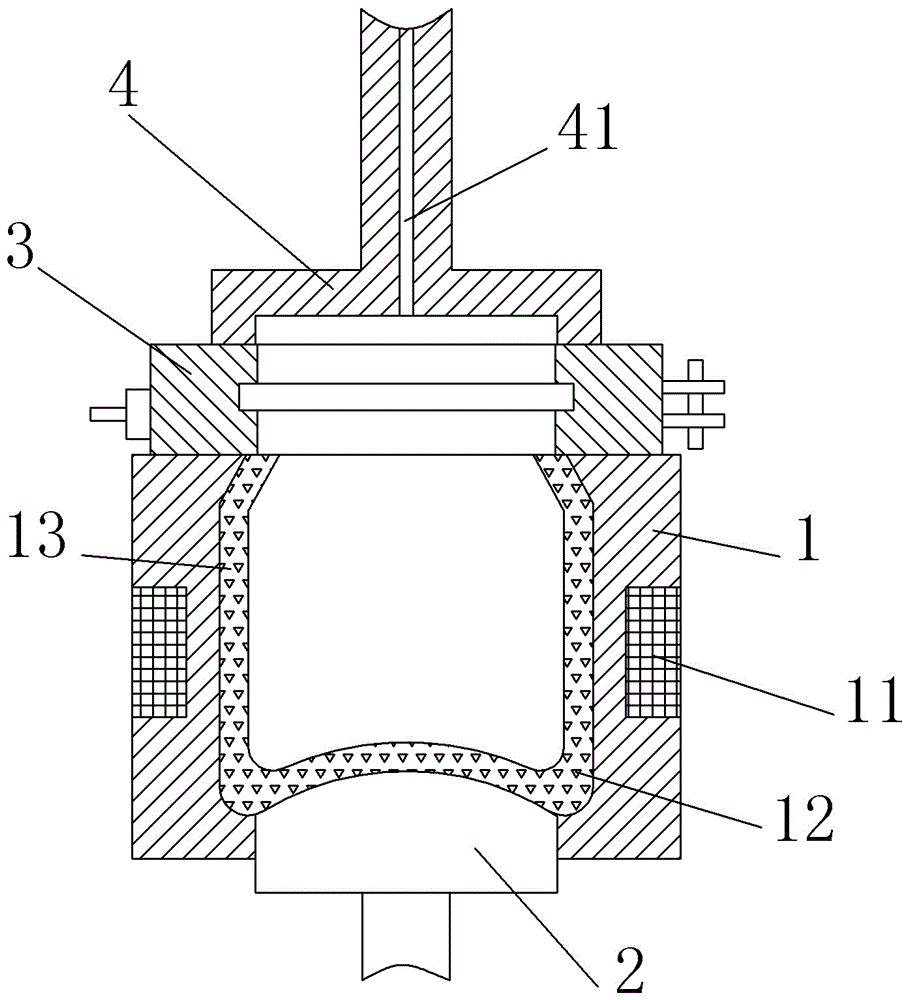

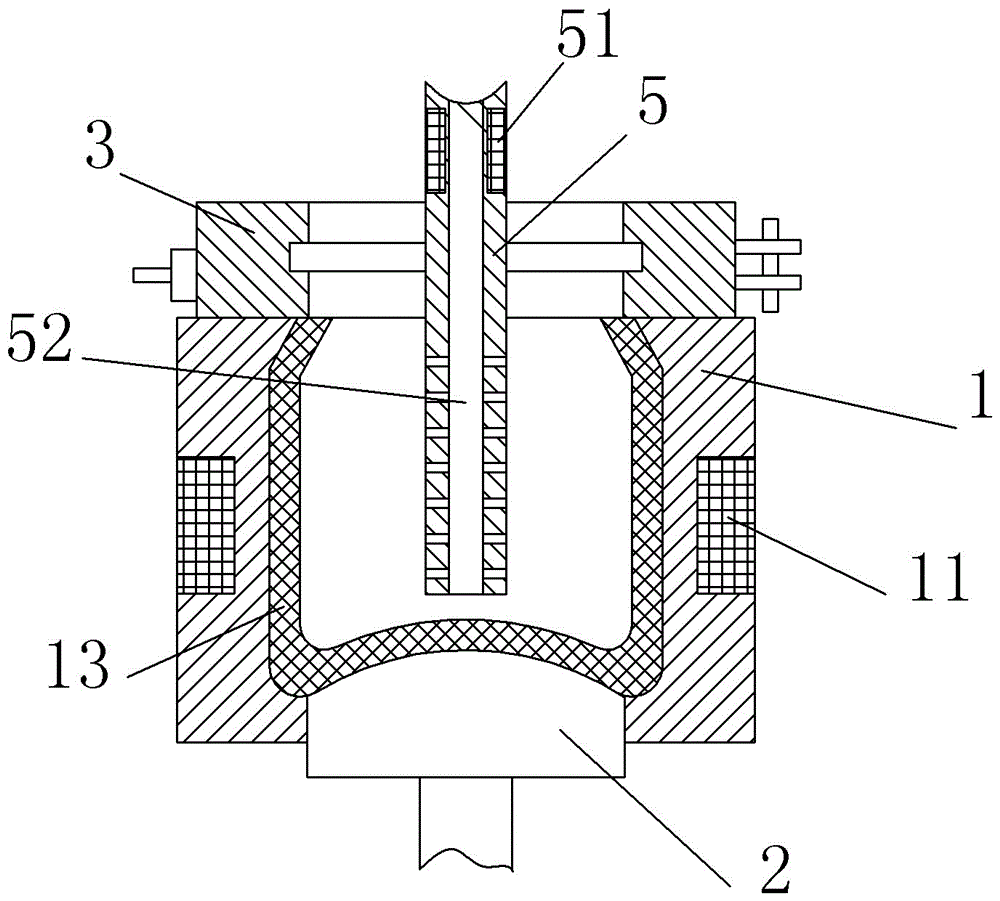

[0018] The reference signs in the drawings of the description include: forming die 1, first excitation coil 11, steel ball 12, glass liquid 13, bottom die 2, mouth die 3, blowing head 4, blowing port 41, ball-absorbing iron rod 5 , the second excitation coil 51 , and the ventilation hole 52 .

[0019] The embodiment is basically as attached figure 1 And attached figure 2 Shown: a kind of glass bottle mould, comprises forming die 1, die 3, base die 2 and blowing head 4, and wherein base die 2 is positioned at the bottom of forming die 1, and die 3 is positioned at the top of forming die 1, and forming die A forming cavity for forming glass bottles is formed between 1 and the bottom mold 2, the bottom of the forming cavity has an arc-shaped chamfer, and the upper part of the forming cavity has a straight chamfer.

[0020] The die 3 is threadedly connected with the formi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com