Two-for-one twister with traveling suction fan

A two-for-one twister and suction fan technology, which is applied in the direction of textiles and papermaking, can solve the problems of untimely dust removal, unsatisfactory dust removal effect, and labor-intensive problems, and achieve timely dust removal, ideal dust removal effect, and labor-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

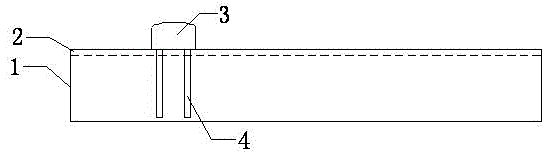

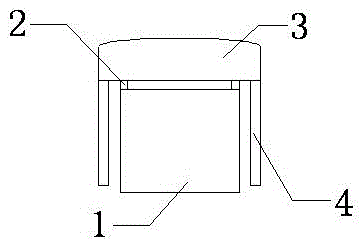

[0015] see figure 1 and figure 2 , the present invention relates to a two-for-one twister with a moving suction fan, which includes a two-for-one twister body 1, the top of the two-for-one twister body 1 is provided with a guide rail 2 along the length direction, and the guide rail 2 is provided with The suction fan 3 has two suction pipes 4 protruding from both sides of the two-for-one twister body 1, and the lower ends of the suction pipes 4 hang down. The lower section of the suction pipe is a straight pipe section, and the upper section of the suction pipe is a bellows section.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap