Knitted fabric with high-strength wear-resistant structure and manufacturing method thereof

A technology for knitted fabrics and a manufacturing method, applied in the field of fabrics and weaving, can solve the problems of poor wear resistance of fabrics, and achieve the effect of improving wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

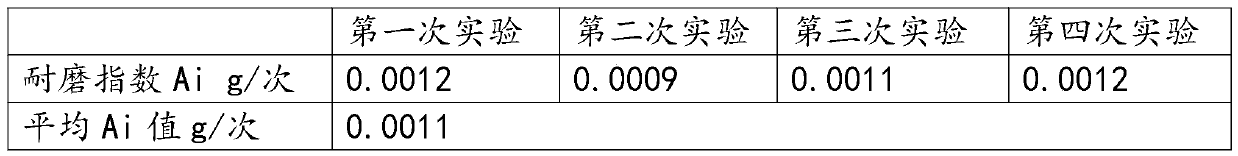

[0044] This embodiment provides a knitted fabric with a high-strength wear-resistant structure. The knitted fabric is a fabric woven from fibers containing aramid fibers; it has a concave-convex double-layer structure.

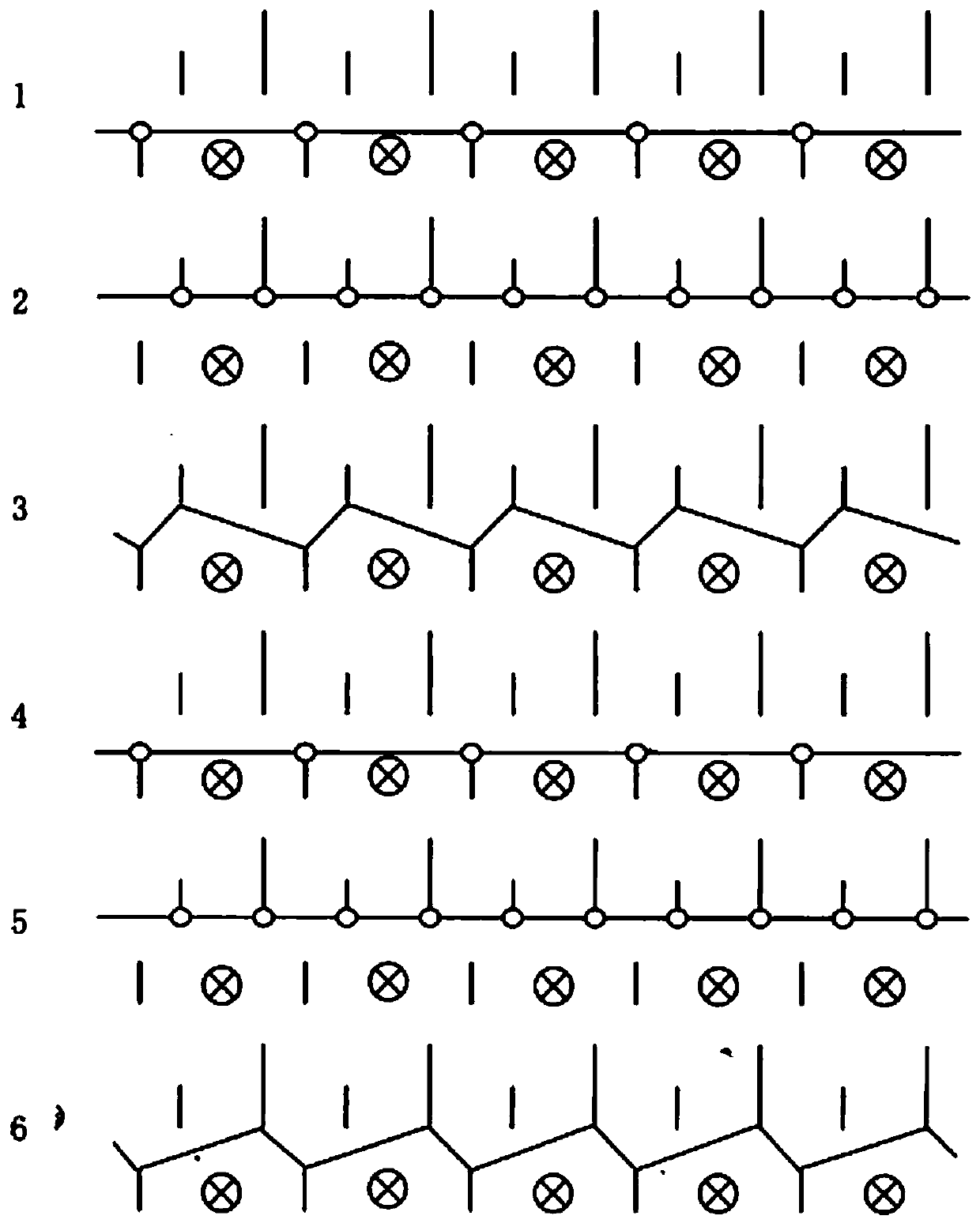

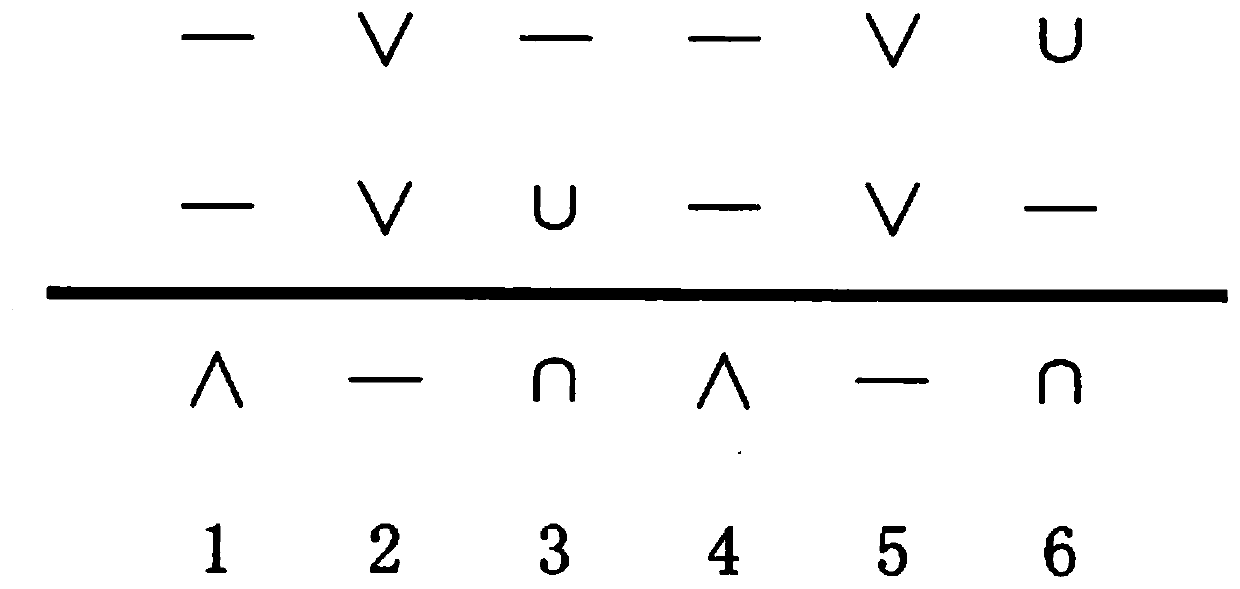

[0045] The weaving method of the concave-convex double-layer structure is as follows:

[0046] 1, in the present embodiment, the yarn selected is:

[0047] 40s / 2 aramid doubling yarn, 150D / 48FDTY polyester low stretch yarn.

[0048] According to the needs of actual fabric weaving, the 40s / 2 aramid doubling yarn can also be replaced by aramid and polyester, cotton yarn, nylon, cotton, hemp yarn, silk, tencel, wool, acrylic, viscose fiber, silk spinning A blended yarn prepared by blending any one or several kinds of yarns;

[0049] The 150D / 48FDTY polyester low-elastic yarn can also be replaced by any one of pure yarns selected from aramid, polyester, cotton yarn, nylon, cotton, linen yarn, silk, tencel, wool, acrylic, viscose fiber, and silk spinning yarn. S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com