Water conveying valve top water stop cavitation preventing method and structural arrangement

A technology of structural arrangement and top stop, which is applied to ship lifting devices, buildings, ship locks, etc., can solve problems such as the impact of ship lock operation efficiency, valve impact vibration, shortened service life, etc., to suppress top stop water cavitation and eliminate impact. type vibration and ensure the effect of safe and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This example is the anti-cavitation arrangement of the top water stop of the water delivery valve of a certain ship lock. The maximum working head of the ship lock is 30m. The water delivery valve adopts the anti-arc gate type. , length 600mm.

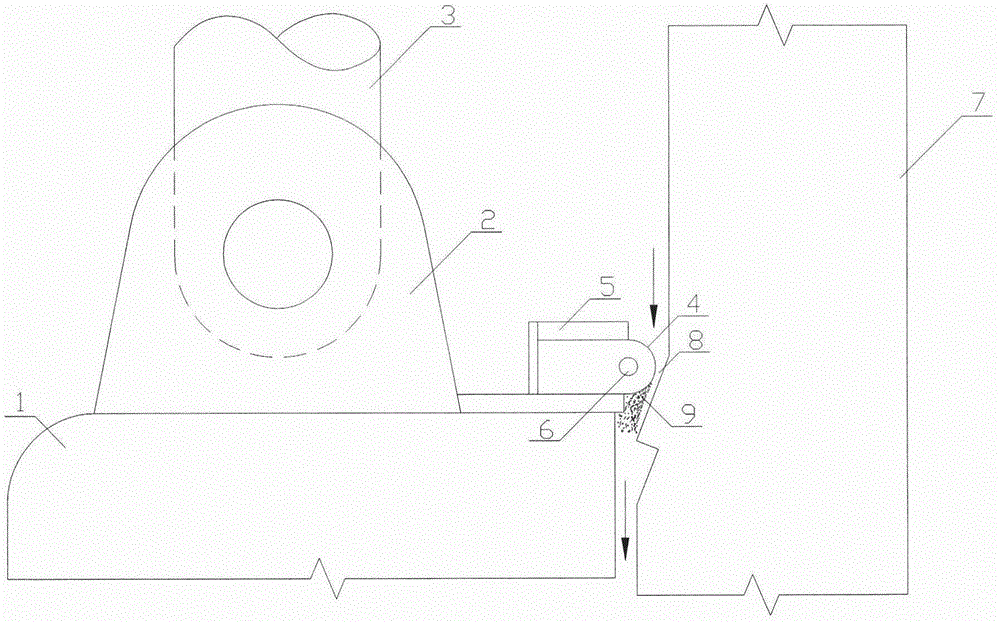

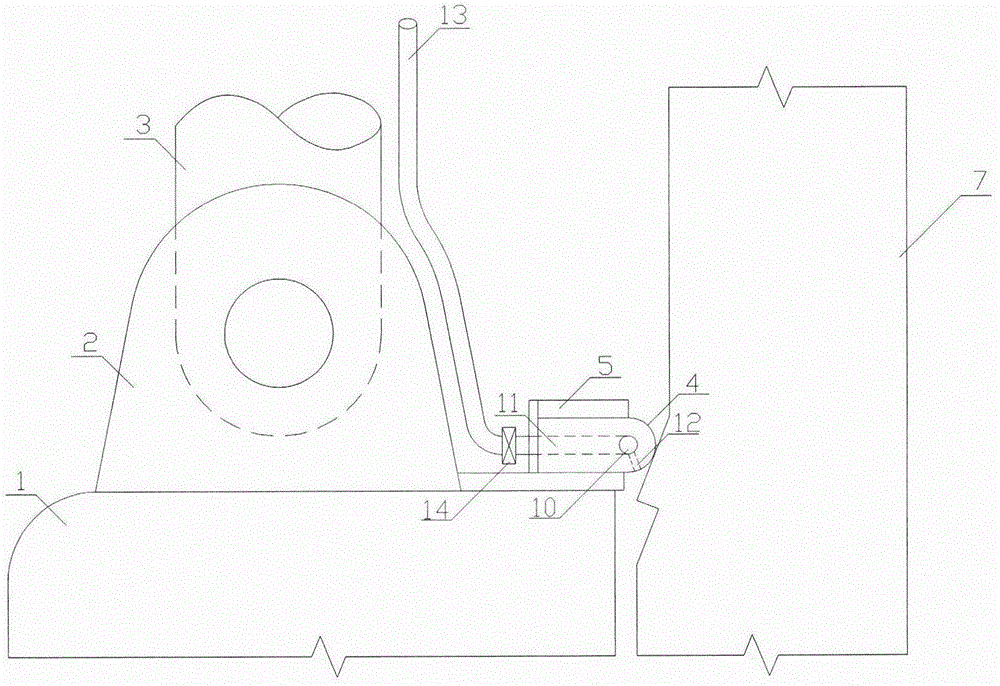

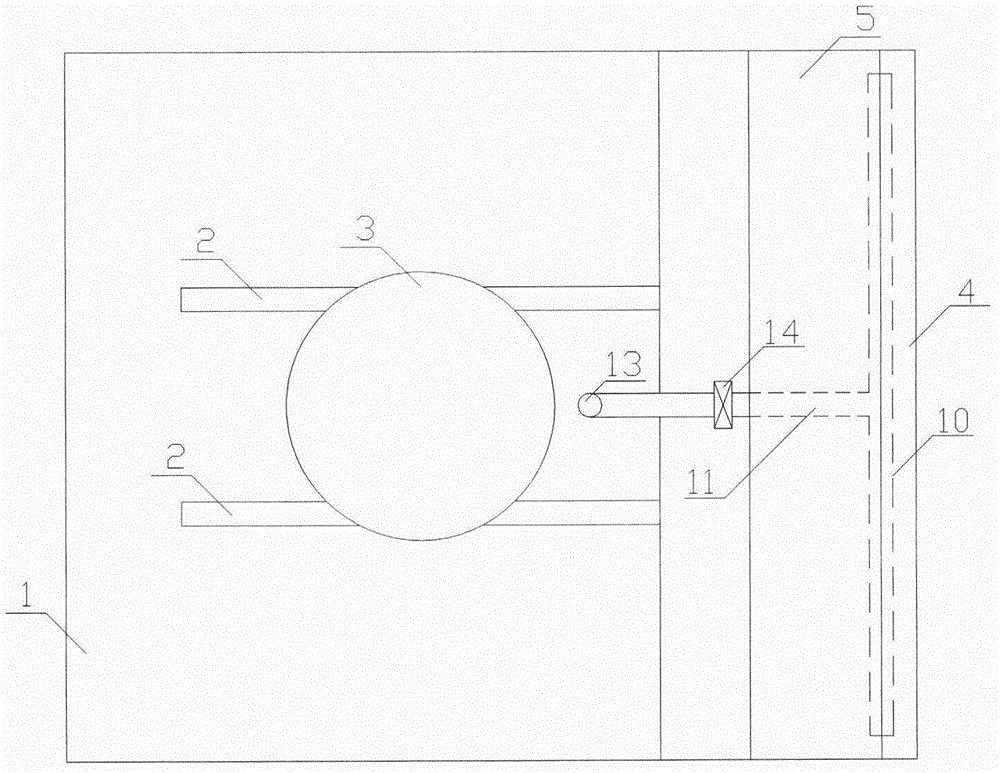

[0031] When the water delivery valve of the present invention is not opened, the water stop and cavitation state is as follows: figure 1 As shown, the front view and the top view of the arrangement of the top water stop and ventilation facilities of the water delivery valve of the present invention are as follows: figure 2 and image 3 As shown, the front view, side view and top view of the top water stop after arranging the ventilation facilities are as follows Figure 4 ~ Figure 6 As shown in the figure, 1 is the door leaf of the water delivery valve, 2 is the lug of the water delivery valve, 3 is the boom, 4 is the top water stop, 5 is the pressure plate, 6 is the cylindrical cavity, 7 is the breast wall, and 8 is the narr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com