Turbine drilling tool motor with emergency stop mechanisms

A turbodrill and stop mechanism technology, which is applied in the field of turbodrill motors and turbodrills, can solve problems such as difficult accidents and complicated drill sticking, and achieve the effect of reducing losses and facilitating handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

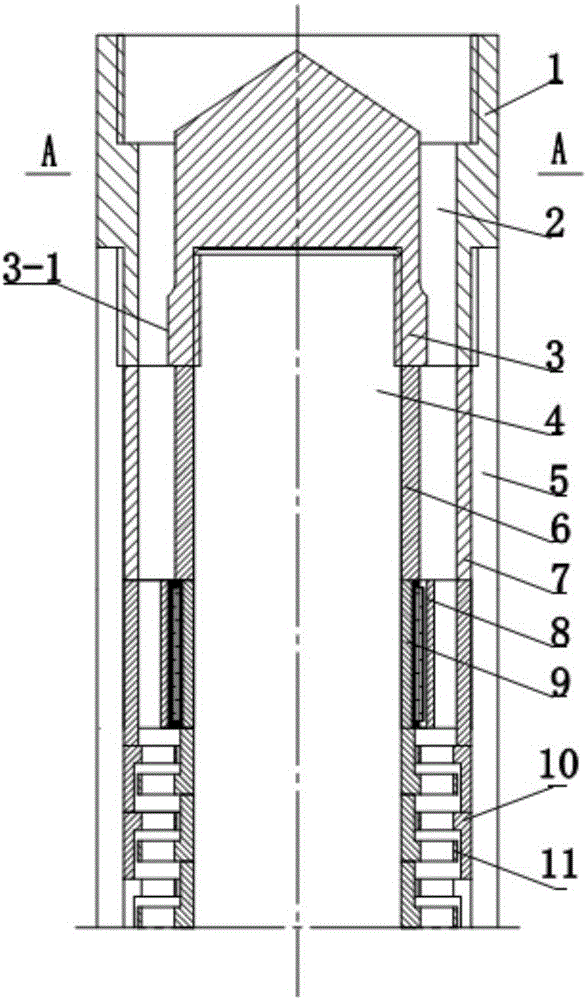

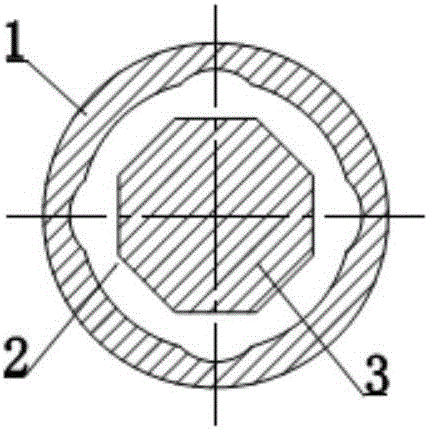

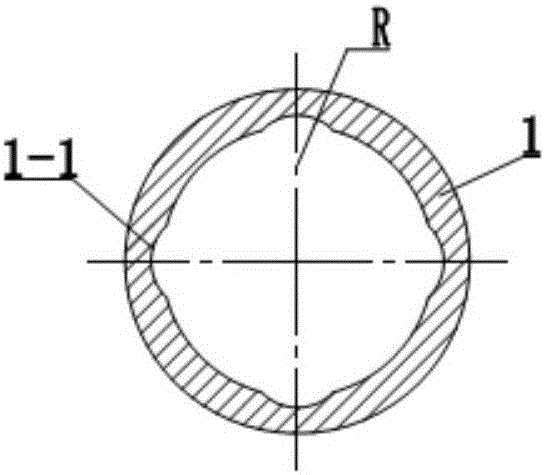

[0024] see figure 1 , the present invention is a turbodrill motor with an emergency stop mechanism, which includes an upper joint 1, a lock nut 3, a turbine motor main shaft 4, a turbo motor housing 5, a main shaft adjustment washer 6, a housing adjustment washer 7, Radial righting bearing static ring 8, radial righting bearing moving ring 9, turbine stator 10 and turbine rotor 11; the lock nut 3, main shaft adjusting washer 6, radial righting bearing moving ring 9 and turbine rotor 11 are from top to bottom The bottom is sequentially set on the turbine motor main shaft 4, and the turbo drilling tool becomes an internal whole that rotates with the turbine rotor 10 when it is working; the upper joint 1, the turbine motor casing 5, the casing adjustment washer 7, and the static ring of the radial centralizing bearing 8 and the turbine stator 10 are connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com