Fireproof check valve

A check valve, valve core technology, applied in the direction of control valve, balance valve, valve device, etc., can solve problems such as difficulty in disassembly and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

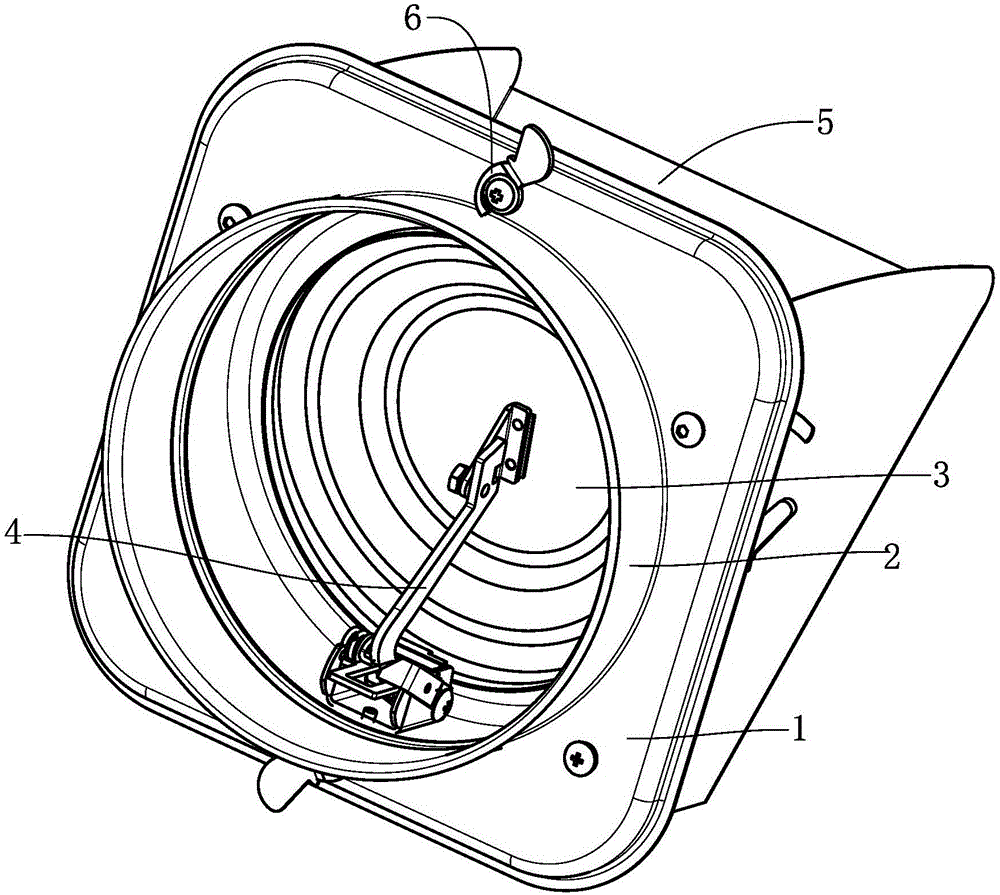

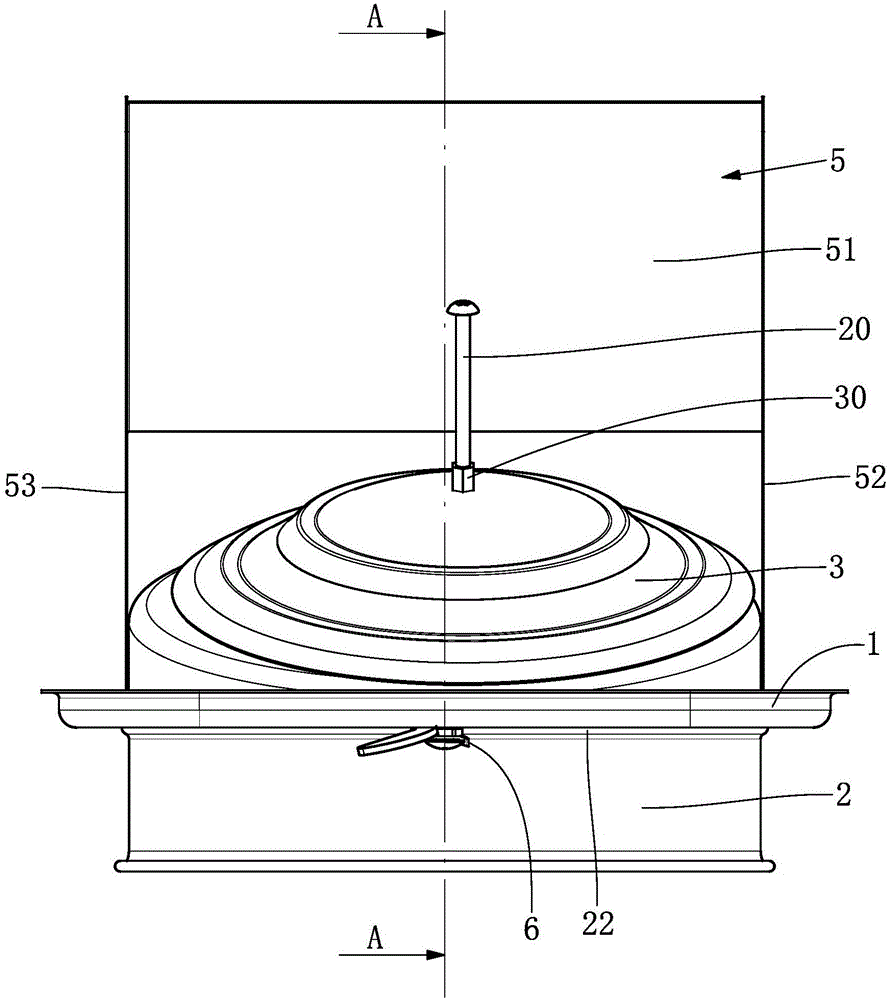

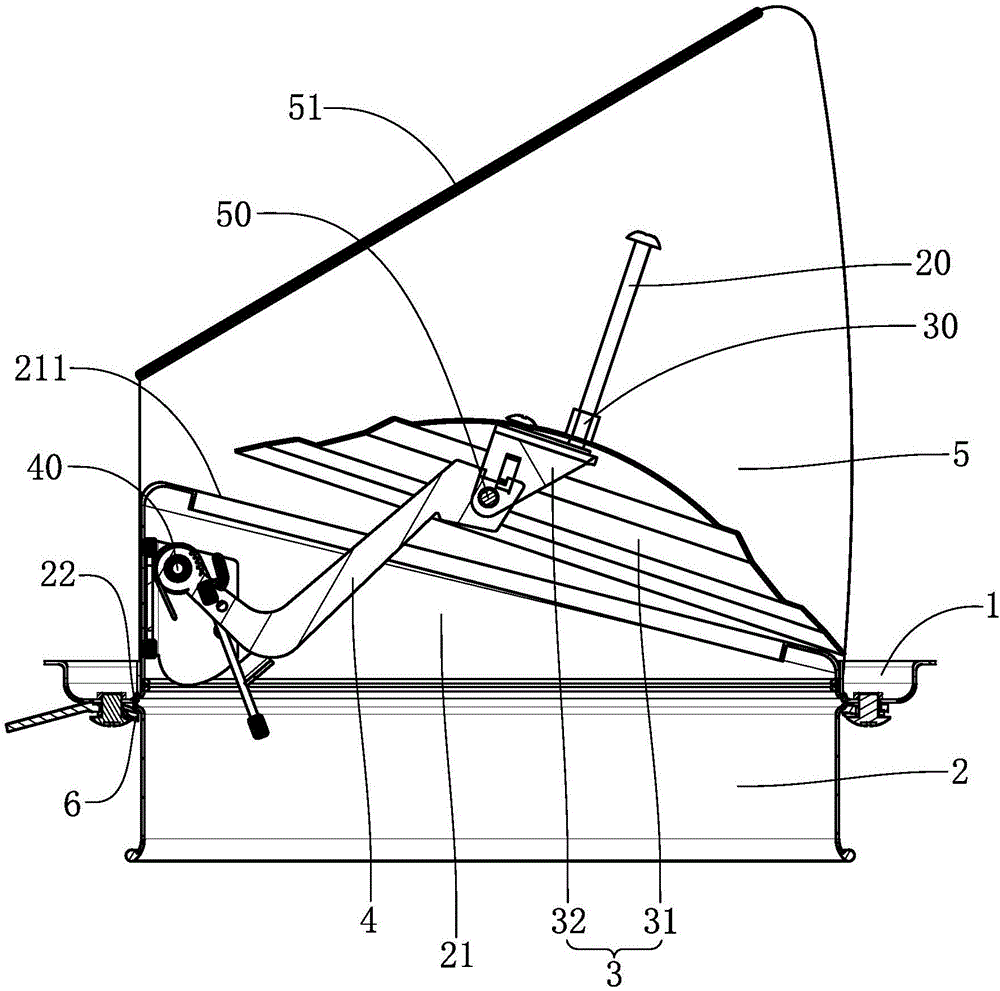

[0029] refer to figure 1 , image 3 and Figure 5 , a fire check valve, comprising a valve body 1, a valve core 2, a valve plate 3 and a connecting rod 4, the valve core 2 is provided with an exhaust port 211, the valve plate 3 is covered on the exhaust port 211, and the valve plate 3 is connected with the valve core 2 through the connecting rod 4, and the valve body 1 is provided with a mounting hole 11, and the valve core 2 is inserted into the mounting hole 11 and detachably installed on the valve body 1.

[0030] refer to figure 1 , the valve core 2 of this embodiment is connected to the valve body 1 through a snap-fit structure. With such a design, the connection strength between the valve core 2 and the valve body 1 is high, and the position accuracy of the valve plate 3 is better. In other embodiments of the present invention, the valve core is threadedly connected with the valve body; or, the valve core is interference fit with the valve body.

[0031] refer to ...

Embodiment 2

[0047] A fire check valve, comprising a valve body, a valve core, a valve plate and a connecting rod, the valve core is provided with an exhaust port, the valve plate cover is arranged on the exhaust port, the valve plate and the valve core are connected through a connecting rod, the valve body There is a mounting hole on the top, the valve core is inserted into the mounting hole and detachably installed on the valve body.

[0048] The valve body of this embodiment is provided with a wind guide cover, and the wind guide cover includes a limit plate corresponding to the valve plate, and the fire check valve also includes a valve for limiting the minimum distance between the valve plate and the limit plate The limit mechanism of the present invention is different from the first embodiment in that: the limit mechanism includes an adjustment rod arranged on the limit plate, and the adjustment rod corresponds to the valve plate.

[0049] In this embodiment, the adjusting rod is sna...

Embodiment 3

[0051] A fire check valve, comprising a valve body, a valve core, a valve plate and a connecting rod, the valve core is provided with an exhaust port, the valve plate cover is arranged on the exhaust port, the valve plate and the valve core are connected through a connecting rod, the valve body There is a mounting hole on the top, the valve core is inserted into the mounting hole and detachably installed on the valve body.

[0052] The valve body of this embodiment is provided with a wind guide cover, and the wind guide cover includes a limit plate corresponding to the valve plate, and the fire check valve also includes a valve for limiting the minimum distance between the valve plate and the limit plate The difference between the limiting mechanism and the first embodiment is that the limiting mechanism includes an adjusting rod and a sound-absorbing block, the adjusting rod and the valve plate are connected as a whole by welding, the sound-absorbing block and the limiting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com