Mechanical automatic oil filling device

An automatic refueling and mechanical technology, applied in mechanical equipment, engine components, engine lubrication, etc., can solve the problems of deterioration of oil quality, physical exertion, and a surprising amount of consumption, and achieve the effect of early replacement and reduction of sub-packaging and other operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention are described below in conjunction with accompanying drawing:

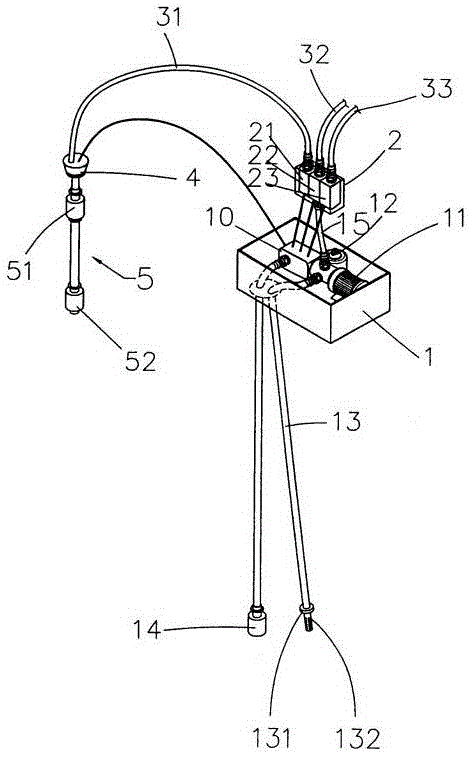

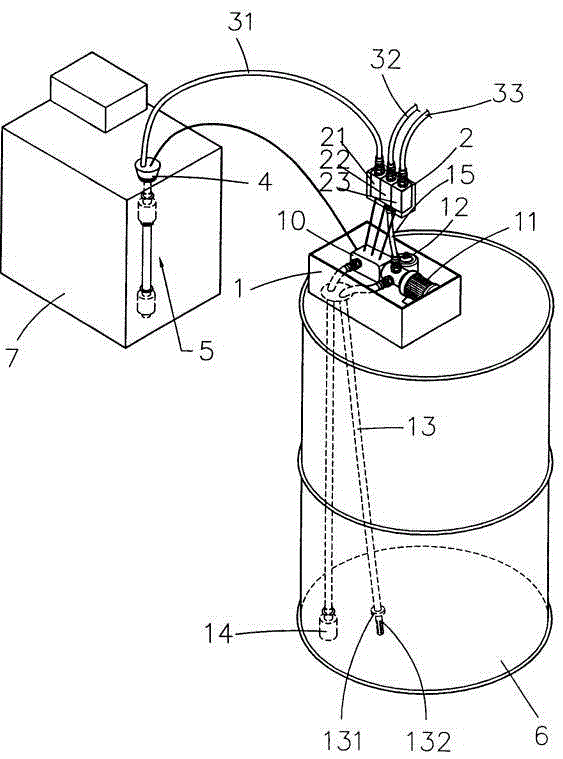

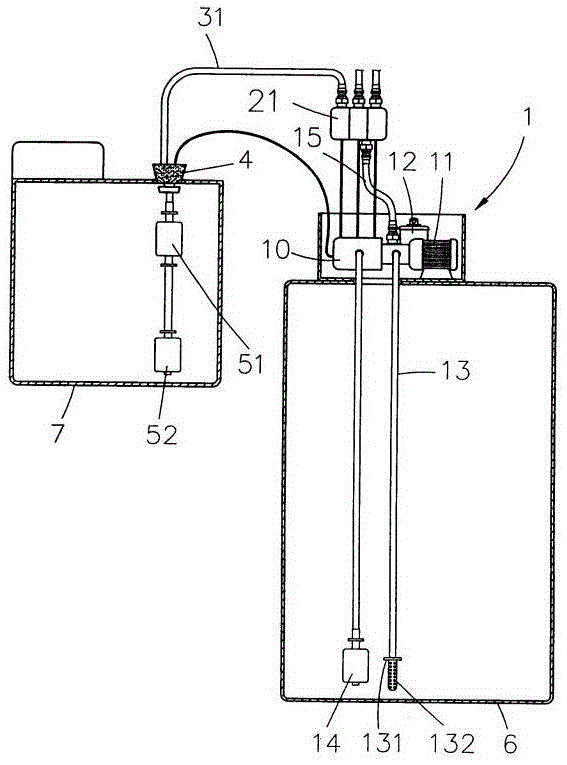

[0030] see figure 1 , is a structural schematic diagram of a preferred embodiment of the present invention, the mechanical automatic oiling device 1 includes a control box 10, a pump 11, a buzzer 12, an oil extraction pipe 13 and a liquid level switch detector 14, wherein, The control box 10 uses an electronic circuit to control its circuit, the oil suction pipe 13 is connected to the pump 11 , and its oil suction end 131 is equipped with a filter structure 132 .

[0031] Can connect an oil outlet pipe 15 from this pump 11, the other end of oil outlet pipe is connected to special electromagnetic valve group 2, and it is connected with this control box 10 and is controlled by it, and from this special electromagnetic valve group 2 each electromagnetic valve 21, 22, 23 can be connected with filling pipes 31, 32, 33 according to the number of oiling machines 7, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com