Industrial and mining lamp assembly

A technology for high bay lamps and components, which is applied to the parts of lighting devices, semiconductor devices of light-emitting elements, and power supplies inside the machine, etc., can solve the problems of reduced installation efficiency, cumbersome and complicated installation process, increased torsional force, etc., and achieves reduced positioning. The use, installation or disassembly of components is convenient and the effect of installation operation is realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to further explain the technical means and functions adopted by the present invention to achieve the predetermined purpose, the specific implementation, structure, features and functions of the application according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. In the following description, particular features, structures, or characteristics of one or more embodiments may be combined in any suitable manner.

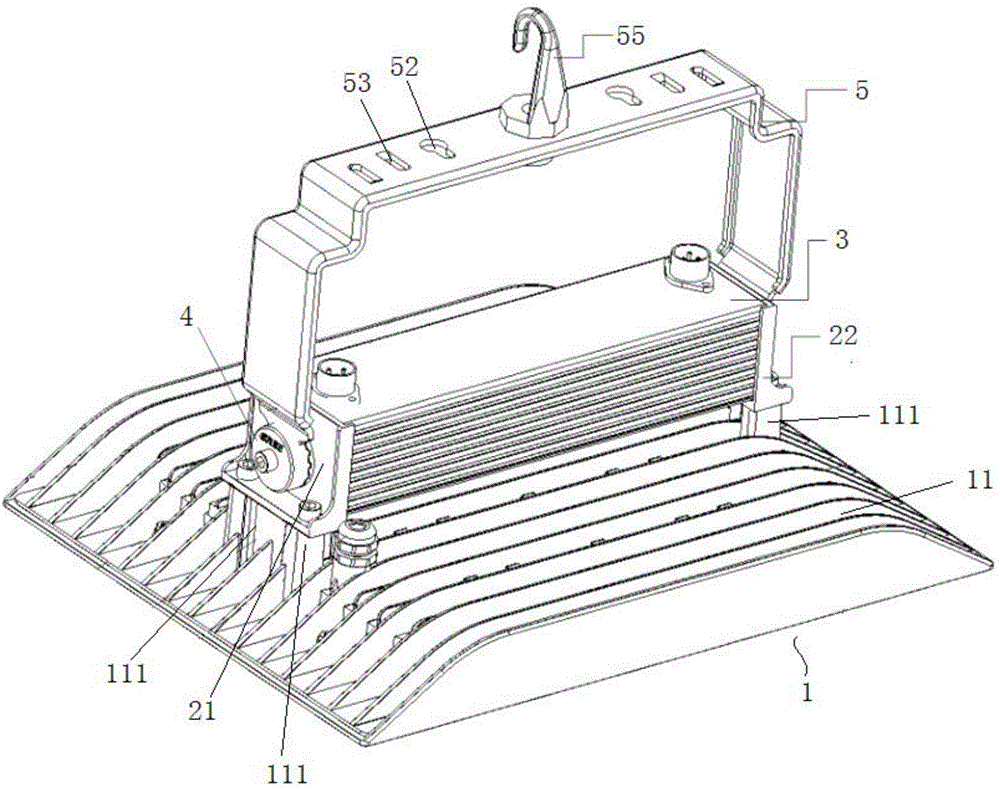

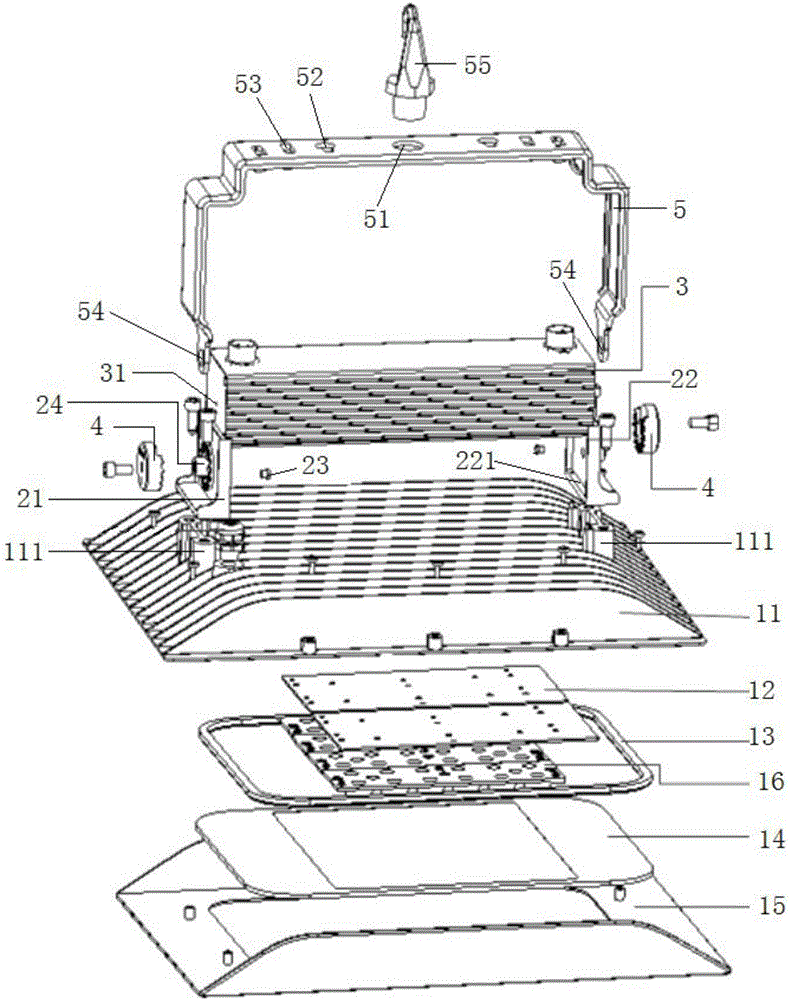

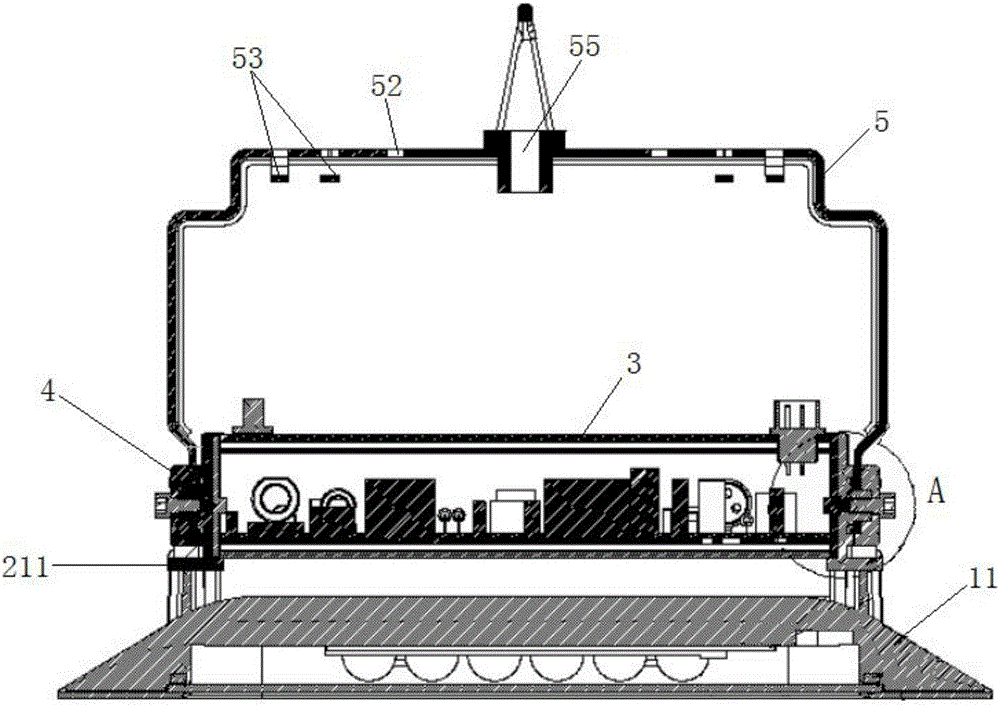

[0045] This specific embodiment relates to a high bay lamp assembly, including:

[0046] A high bay lamp 1, the high bay lamp 1 includes a connection housing 11, and a lamp body connected to the connection housing 11;

[0047] a connection seat, the connection seat is connected to the connection housing 11;

[0048] The driving power supply 3 is used to provide electric energy for the lamp body to emit light, and the driving power supply 3 is installed on the connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com