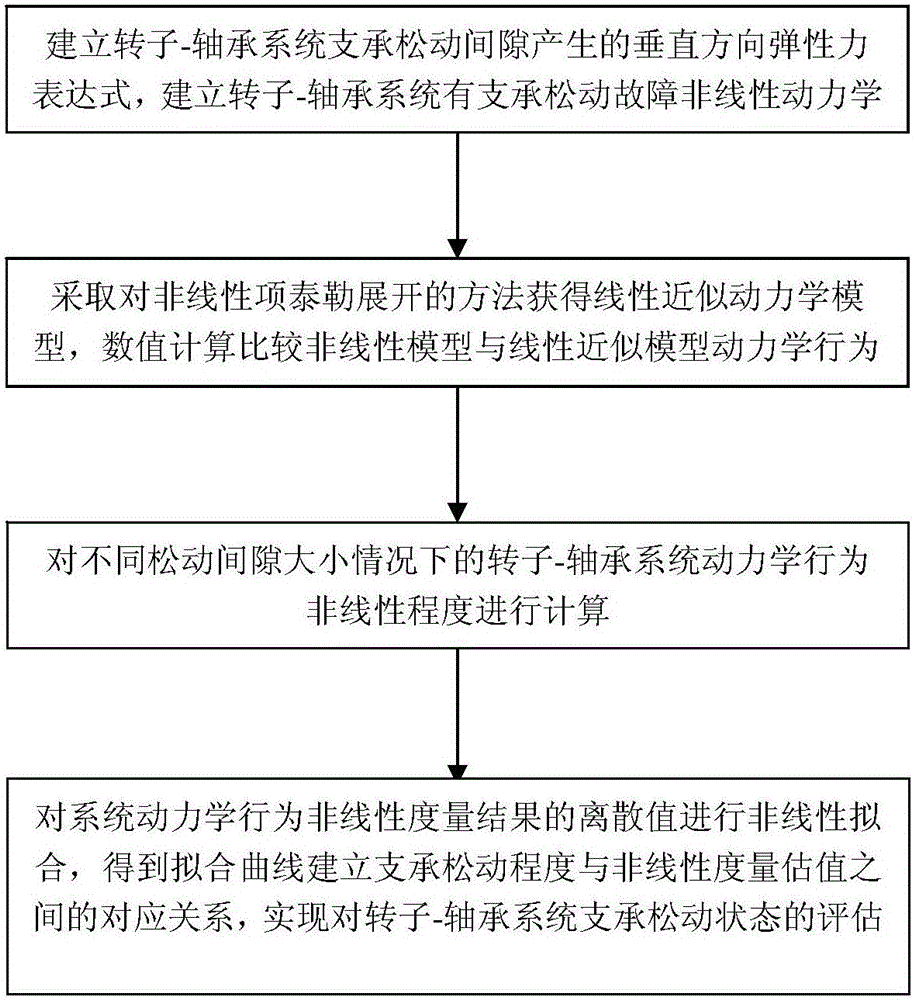

Rotor-bearing system pedestal looseness state assessment method

A state evaluation and system dynamics technology, applied in the testing of machine/structural components, testing of mechanical components, instruments, etc., can solve problems such as state evaluation without support looseness, to prevent catastrophic accidents, ensure accuracy and reliability , The effect of preventing large gaps from loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

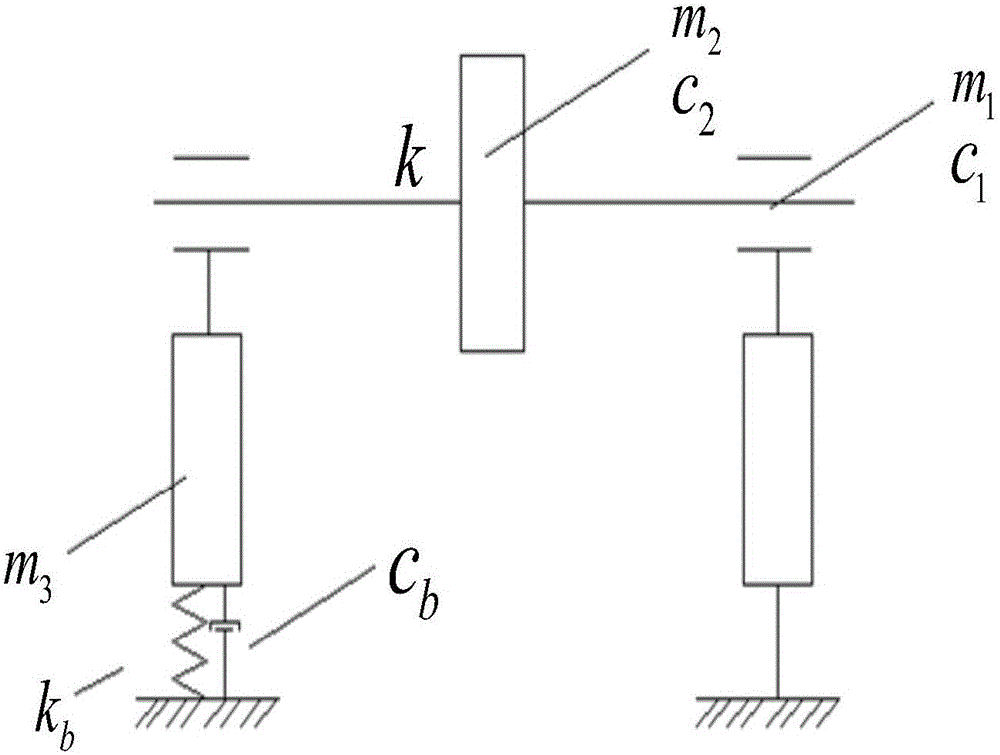

[0101] Select the rotor-sliding bearing as the calculation object, as follows:

[0102] In view of the strong nonlinear dynamic behavior that can be produced by the rotor-sliding bearing system, this paper uses the Runge-Kutta method with 4-5 step variable step size to simulate and calculate the dynamic model without loosening and the loosening dynamic model with support respectively. In order to ensure the convergence of the solution and reduce calculation errors, the integration step size and other parameters are selected in the simulation as h=π / 512; e=0.5×10 -4 m; m 1 = 32.1 kg; m 2 = 4kg; m 3 =10kg; k=2.5×10 7 N / m; k b1 =7.5×10 9 N / m; k b3 =7.5×10 7 N / m; c 1 =1050N·s / m; c 2 =2100N·s / m; c b1 =350N·s / m; c b2 =100N·s / m; c b3 =500N·s / m.

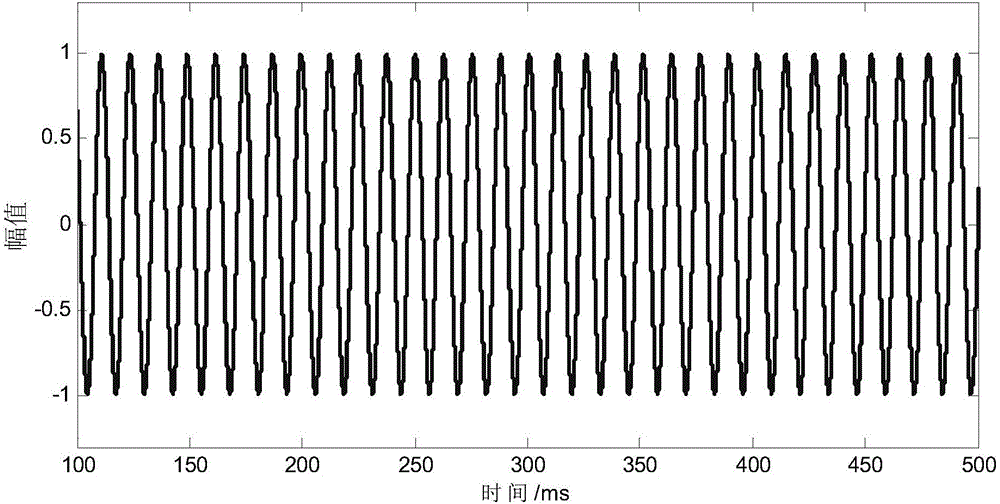

[0103] Take X=[x 1 ,y 1 ,x 2 ,y 2 ,x 3 ,y 3 ,y 4 ] is processed as follows, X'=X / c, X'=X' / (cω), X'=X' / (cω 2 ), where c is the average thickness of the lubricating film, and ω is the angular velocity of the shaft. Under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com