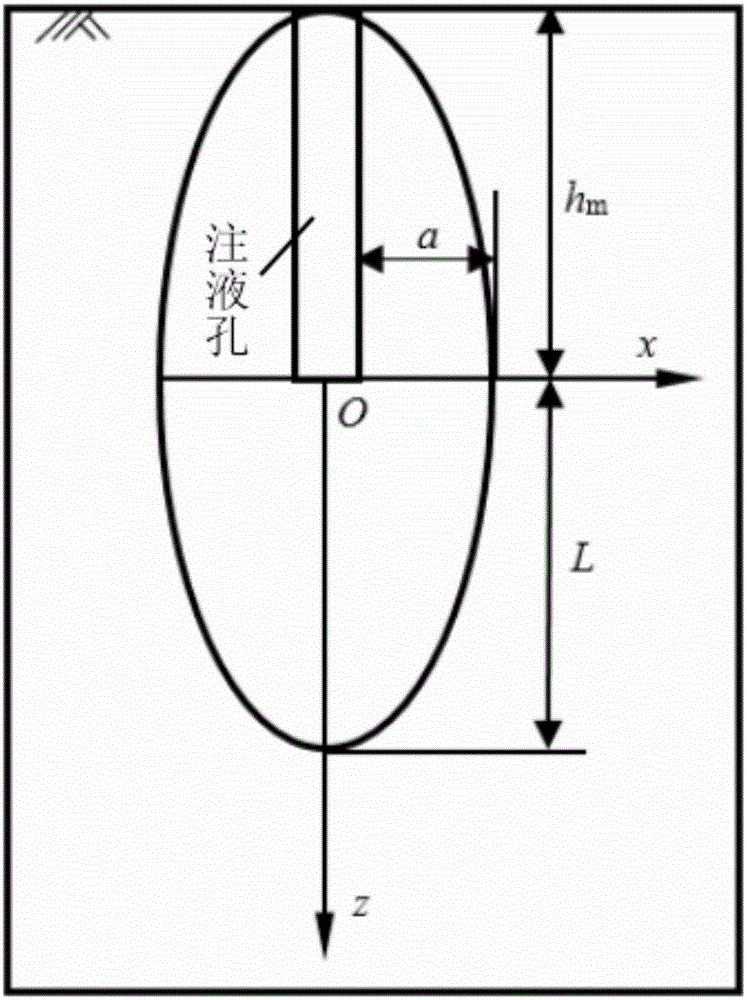

Calculating method of distribution of volumetric water content around liquid injection hole for in situ leaching of ion type rare earth

A volumetric moisture content, ionic rare earth technology, applied in soil material testing, analytical materials, instruments, etc., can solve the problems of insufficient recycled resources, blind areas of leaching, and difficulty in recycling resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

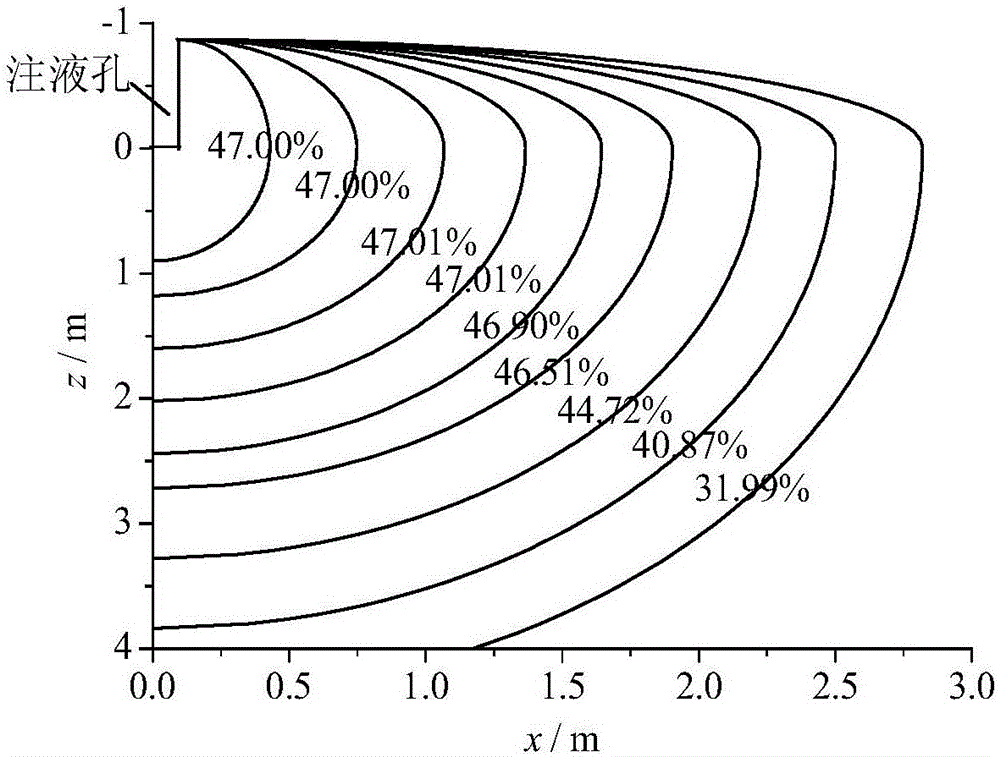

[0060] Apply the present invention to select a flat site (closed test) in a rare earth mining area in Zudong, Longnan, excavate to form a step, and adopt the TEN type tensiometer developed by the Nanjing Soil Institute of the Chinese Academy of Sciences to test the soil-water characteristic curve of the ore body. Technically test the initial moisture content and porosity of the ore body, and use the FDS-100 moisture sensor to test the volumetric moisture content at different moments during the infiltration process. The implementation process is as follows:

[0061] Step 1: Test the soil-water characteristic curve of the ore body,

[0062] The TEN tensiometer developed by the Nanjing Soil Institute of the Chinese Academy of Sciences was used to test the matrix suction corresponding to different water contents of the ore body, and the test data was fitted by the relationship (1), and the saturated volume water content was 47.09%, and the residual volume water content was 6.08%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com