Biomass pyrolysis heat supply device and use method thereof

A biomass pyrolysis and heating device technology, applied in the field of biomass pyrolysis heating devices, can solve the problems of waste gas containing a large amount of heat, environmental pollution, waste, etc., achieve scientific and reasonable adjacent spacing, reduce waste, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

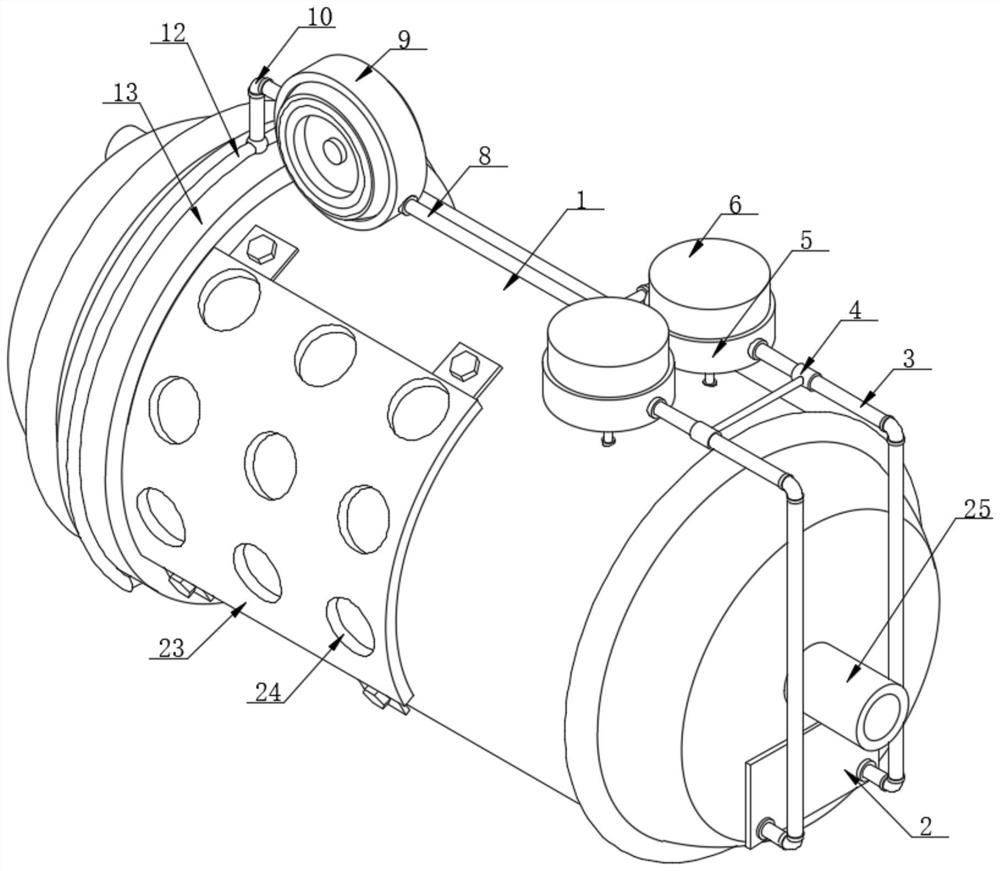

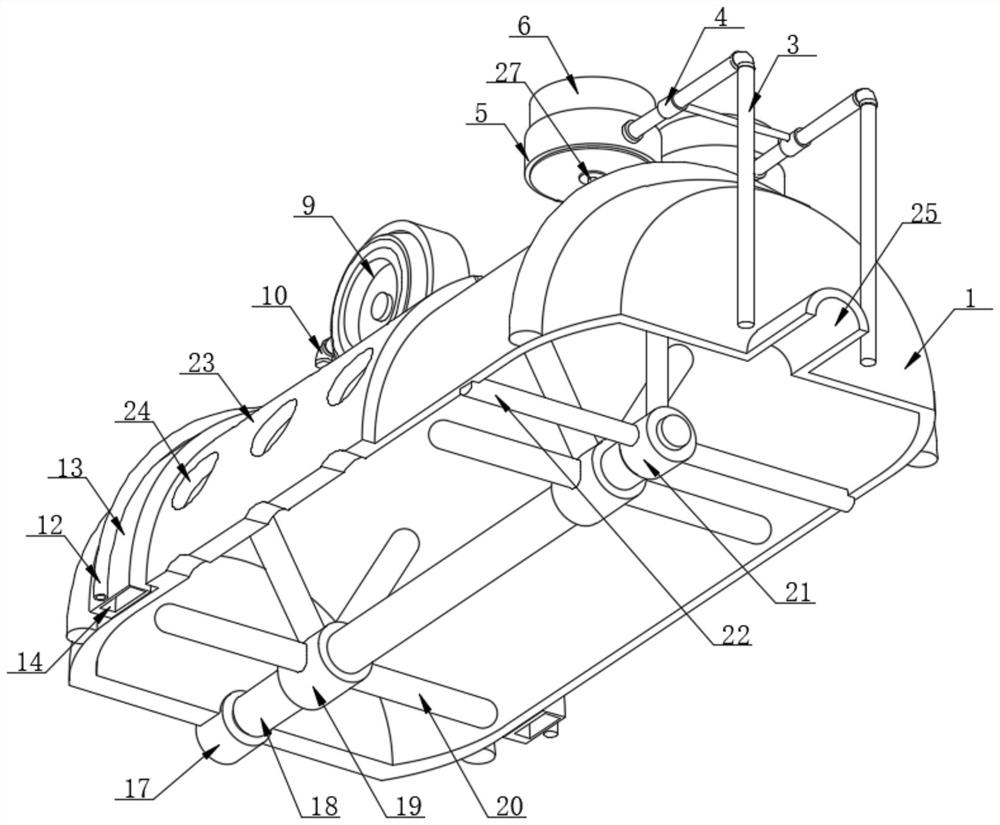

[0030] Such as figure 1 , figure 2 , Figure 4 and Figure 5As shown, the present invention provides a biomass pyrolysis heat supply device, comprising a pyrolysis furnace 1, the right side of the pyrolysis furnace 1 is fixedly connected with a mounting plate 2, and the right side of the mounting plate 2 is connected to two first The left end of conduit 3 is communicated, and two first conduits 3 pass mounting plate 2 and are communicated with the right side of pyrolysis furnace 1, and the other end of two first conduits 3 passes two protective sleeves 5 respectively and two The outer surface of the filter barrel 6 is connected, the protective cover 5 is sleeved on the outer surface of the filter barrel 6, and the outer surfaces of the two filter barrels 6 are connected with the right ends of the two second conduits 7 respectively, and the two second conduits 7 The other end of the same cluster tube 8 is connected with the right end, the left end of the cluster tube 8 is c...

Embodiment 2

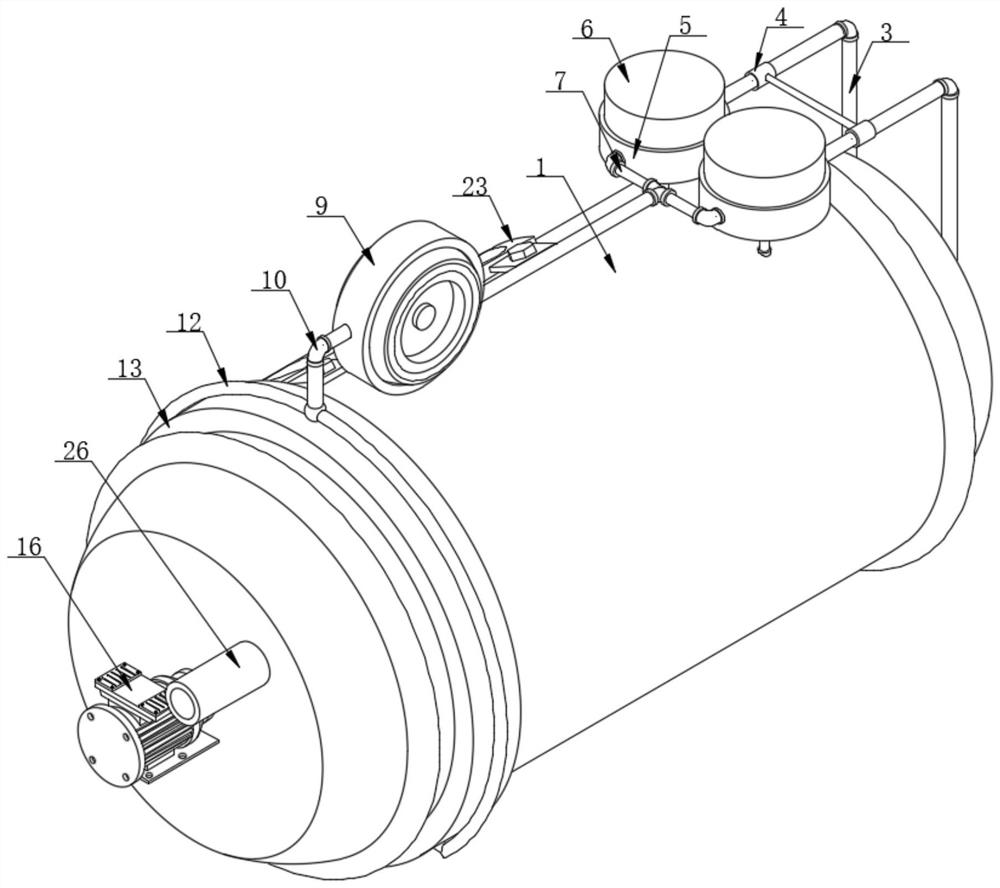

[0037] On the basis of Example 1, as figure 1 , image 3 and Figure 6 As shown, the present invention provides a biomass pyrolysis heat supply device, the left side of the pyrolysis furnace 1 is fixedly connected to the right side of the driving device 16, and the drive shaft on the right side of the driving device 16 is connected to the left end of the rotating device 17 Fixedly connected, the rotating device 17 is clamped on the left side of the pyrolysis furnace 1, the right end of the rotating device 17 is fixedly connected with the left end of the connecting shaft 18, and the outer surface of the connecting shaft 18 is fixedly connected with a stirring shaft 19.

[0038] The outer surface of the stirring shaft 19 is provided with several stirring rods 20, the right end of the connecting shaft 18 is clamped with a positioning frame 21, the outer surface of the positioning frame 21 is fixedly connected with the inner wall of the pyrolysis furnace 1 by four positioning col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com