Novel power cable joint box

A technology for power cables and splice boxes, applied to cable joints, instruments, measuring devices, etc., can solve problems such as inability to protect cables, poor waterproof performance, affect the performance and scope of application of cable splice boxes, and achieve effective protection and good waterproofing performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

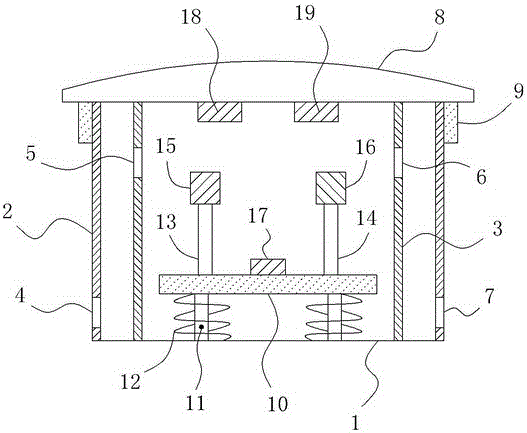

[0013] Such as figure 1 As shown, a new type of power cable splice box includes a cylindrical box body 1, the vertical side wall of the box body 1 is a double-layer structure including an outer layer body 2 and an inner layer body 3, and the outer layer body 2 The lower left side is also provided with an outer wire inlet 4, and the upper left side of the inner layer body 3 is also provided with an inner wire inlet 5, and the upper right side of the inner layer body 3 is also provided with an inner wire outlet hole 6. The lower part of the right side of 2 is also provided with an external wire hole 7, and an external thread is also provided on the top of the outer layer body 2, so that external rainwater, etc. can be effectively prevented from entering the inside of the box body 1 through each wire inlet hole and wire outlet hole; The top of the box body 1 is also provided with a cover body 8, and the bottom end of the cover body 8 is also provided with an annular plate 9 exten...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap