Frequency converter structure with built-in EMI circuit

A frequency converter and circuit technology, applied in electrical components, output power conversion devices, cooling/ventilation/heating transformation, etc., can solve the problems of low common-mode suppression ability, heat dissipation, and high temperature in the middle and high frequency bands, and achieve enhanced filtering of noise ability, improved ease of use, and strong filtering capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The detailed description and technical content of the present invention will be described as follows with the accompanying drawings, but the attached drawings are only for illustration purposes and are not intended to limit the present invention.

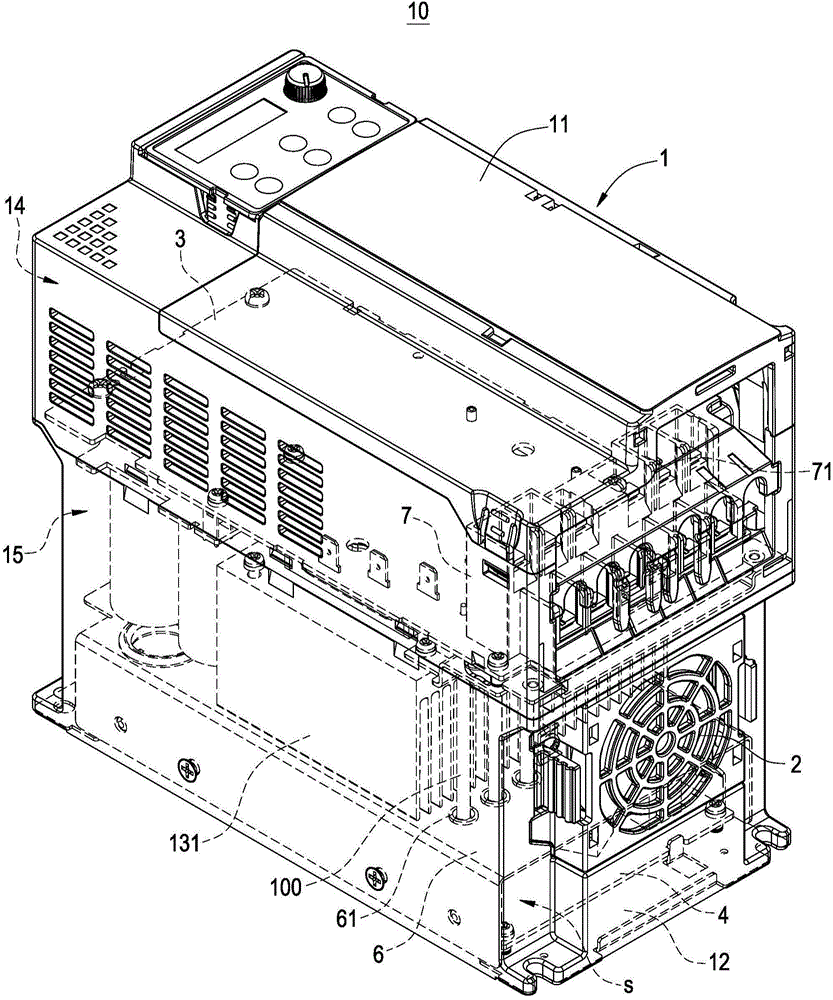

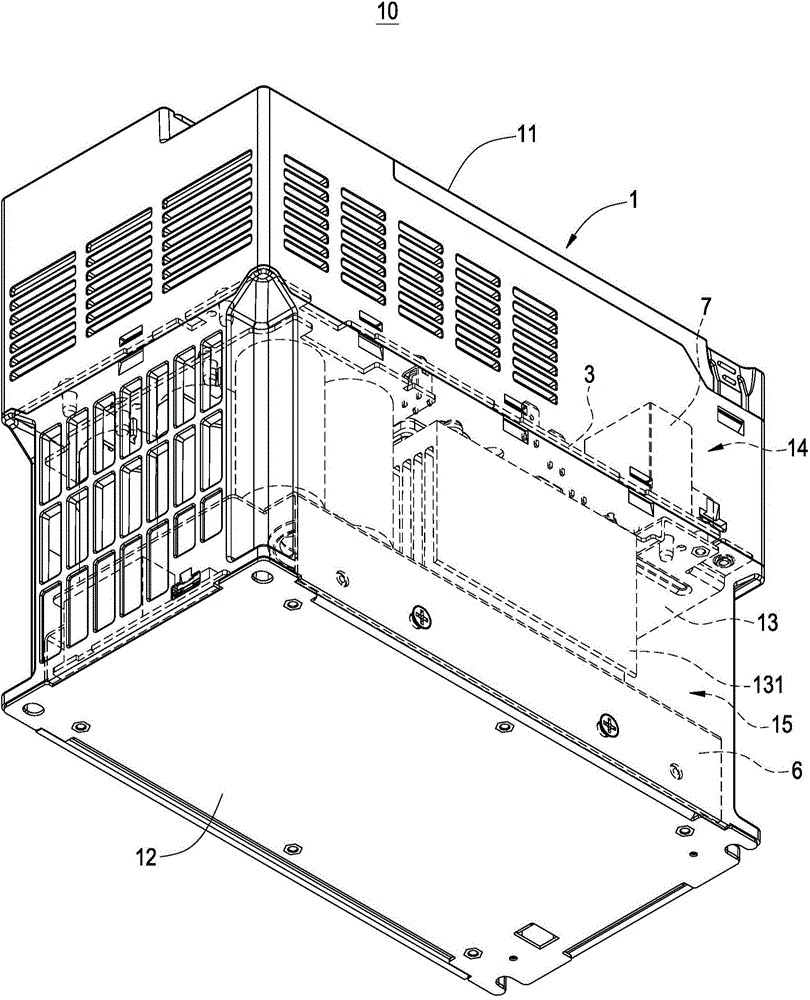

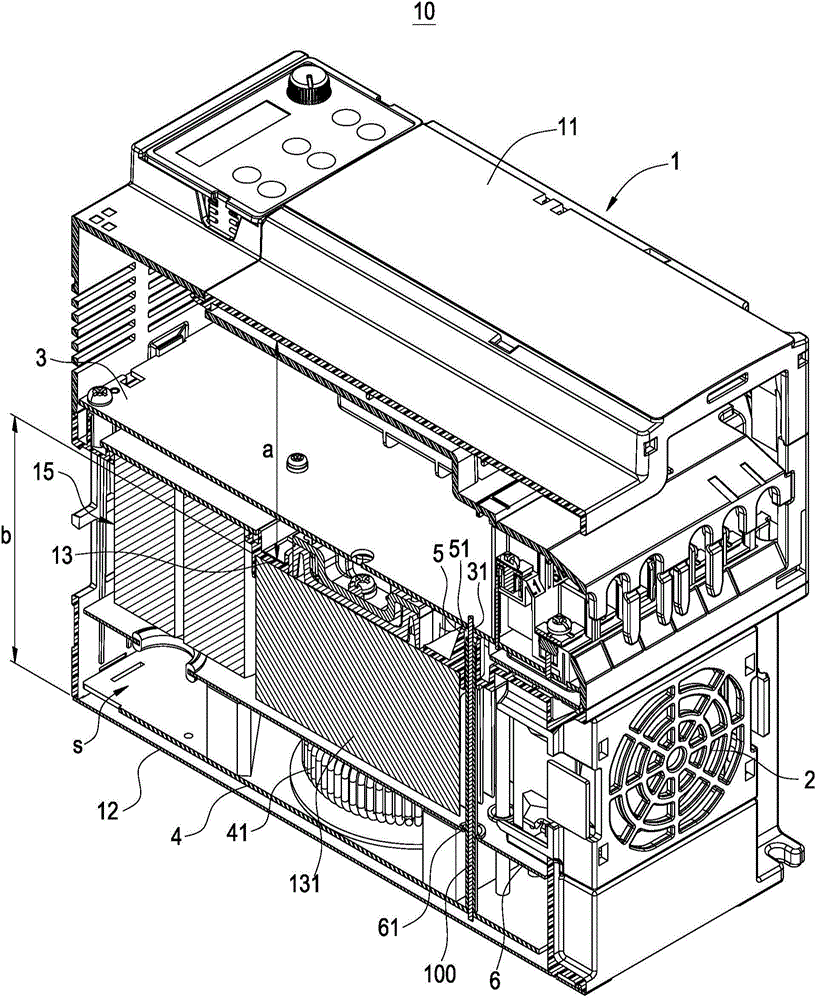

[0065] Please refer to Figure 1 to Figure 8 As shown, the present invention provides an inverter structure with built-in EMI circuit. The inverter structure 10 mainly includes a box 1 , a fan 2 , a power supply circuit board 3 and an EMI circuit board 4 .

[0066] like Figure 1 to Figure 3 As shown, the box body 1 has a relative top plate 11 and a bottom plate 12, and a partition plate 13 is arranged between the top plate 11 and the bottom plate 12. The partition plate 13 separates the box body 1 into an upper chamber 14 and a lower chamber. The chamber 15 and the bottom plate 12 are made of conductive material. The partition plate 13 is connected with a heat dissipation fin set 131 , and the heat dissipation fin set 131 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com