Semi-feeding whole-stalk type multi-row combined sugarcane harvester

A combined, semi-feeding technology, used in harvesters, agricultural machinery and implements, applications, etc., can solve problems such as mildew, excessive sugar loss, and affect quality, and achieve convenient work adjustment, maintenance probability and maintenance. Low cost and improved harvesting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technology will be further described below in conjunction with the accompanying drawings.

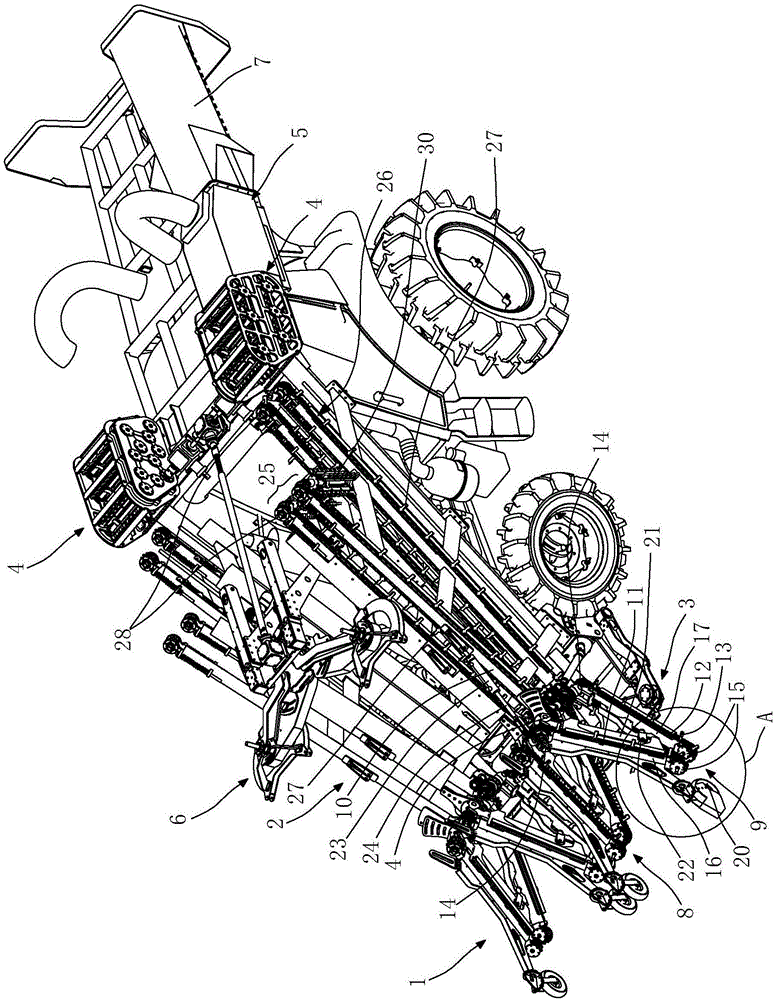

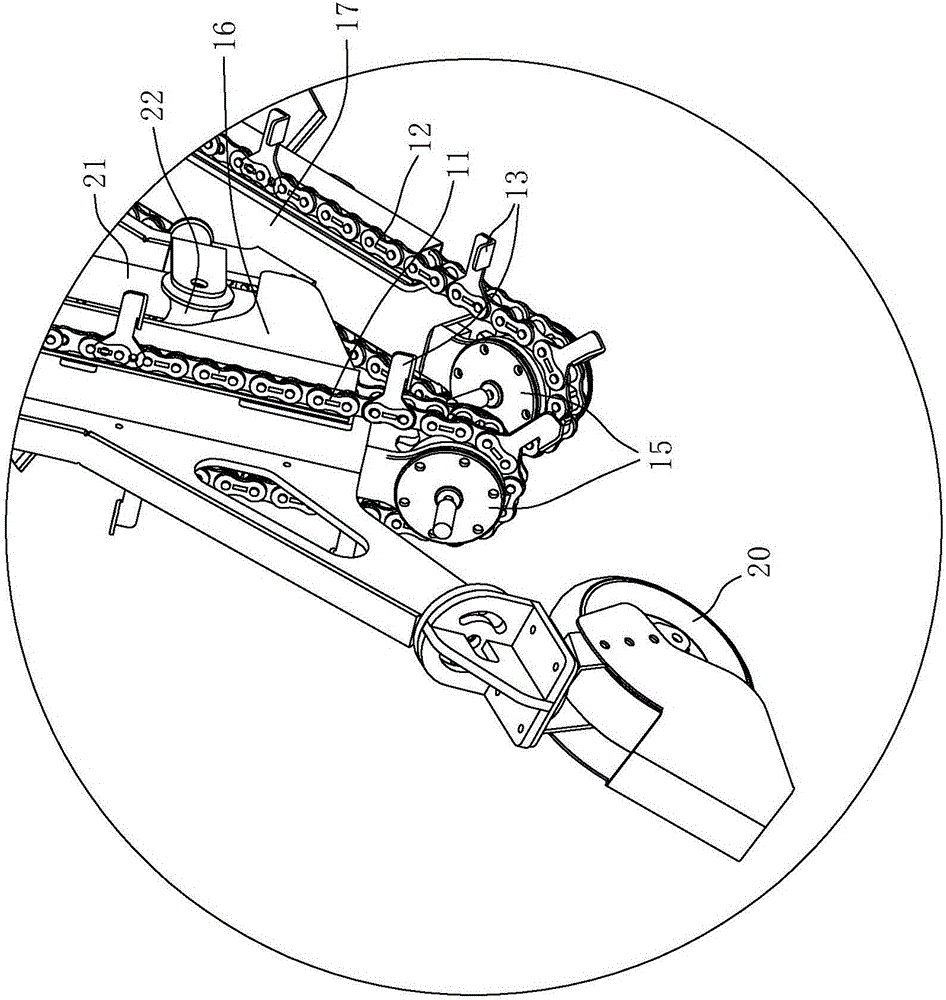

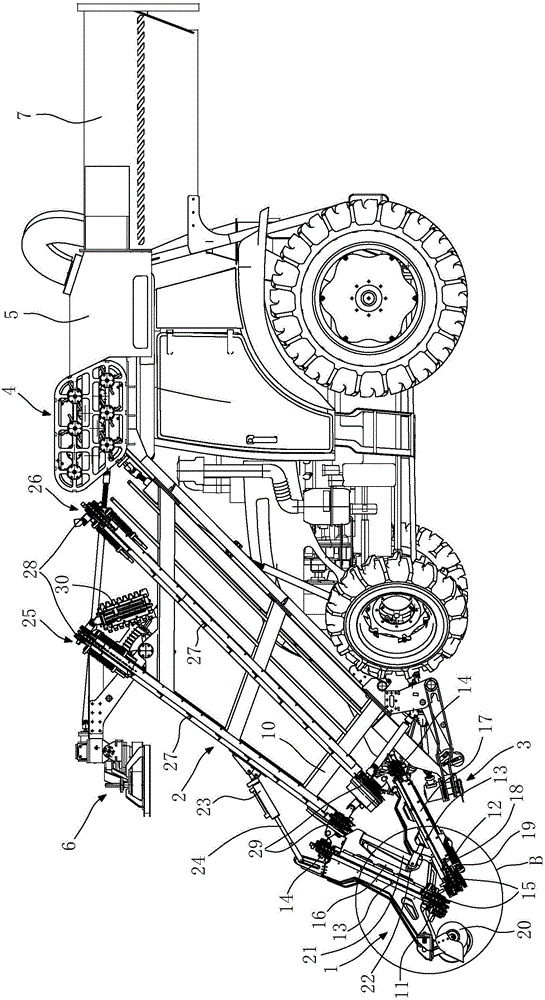

[0045] A combined sugarcane harvester that can harvest two rows of sugarcane at the same time with a semi-feeding whole rod type. The technical features of the machine are as follows: a high-horsepower tractor is used to realize the driving and variable speed power, more than one set of harvesting systems, and each set of harvesting systems The modular division is adopted in the overall unit design, which is divided into multiple module groups for integration according to the performance and process. The harvester system is unitized, and its harvesting unit is configured on the traveling mechanism, which can work independently or combine multiple harvesting units for synchronous operation. It not only integrates and optimizes supporting production resources, but also facilitates the rapid industrialization of new technology products and enterprise standardization.

[0046] Ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com