Gas stripping sludge discharge device

A sludge discharge device and air lift technology, which is applied in the feeding/discharging device of the sedimentation tank, sludge treatment, water/sludge/sewage treatment, etc. To achieve the effect of smooth air outlet, reduce equipment energy consumption, and prevent blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

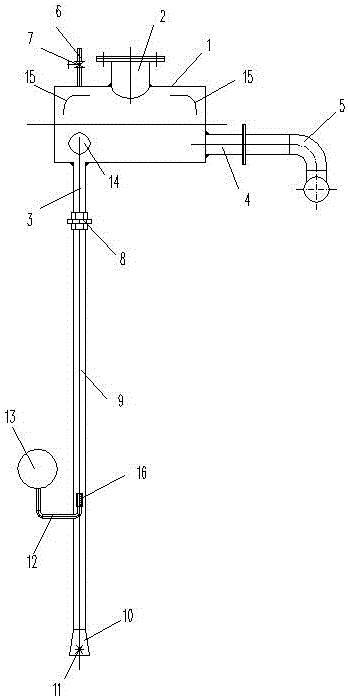

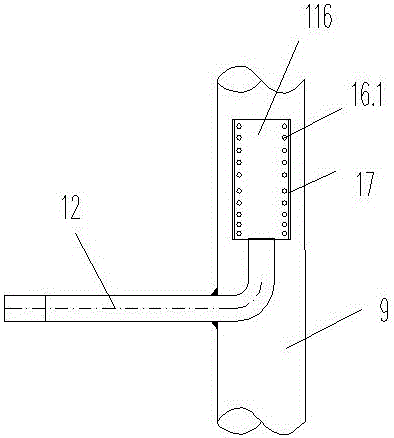

[0011] Embodiment 1: A kind of air lifting and sludge removal device, comprising a horizontal gas tank 1, a hand hole 2 is arranged on the side wall of the upper end of the gas tank 1, a mud inlet pipe 3 is arranged on the side wall near the left end of the lower end of the gas tank 1, and the gas tank 1 There is a mud outlet pipe 4 near the bottom of the right end, the mud outlet pipe 4 is connected to the sludge main pipe 5 through a flange, an exhaust pipe 6 is arranged on the side of the hand hole 2, a gate valve 7 is arranged on the exhaust pipe 6, and the mud inlet pipe 3 passes through The joint 8 is connected to the suction pipe 9, the bottom of the suction pipe 9 is provided with a suction bell mouth 10, and the center of the suction bell mouth 10 is provided with a rice-shaped rotating paddle 11, and the suction pipe 9 is located at 1 / 3 from bottom to top. An air intake pipe 12 is arranged at the height, and the air intake pipe 12 is connected to the blower 13. The ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com