Vacuum suction filtration equipment with suction filtration bottle with liquid draining function

A technology of vacuum suction filtration and suction filtration bottle, which is applied in the direction of fixed filter element filter, filtration separation, gravity filter, etc. It can solve the problems of filtrate discharge and complex discharge of filtrate, and achieve simplified discharge process, short discharge time and easy operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

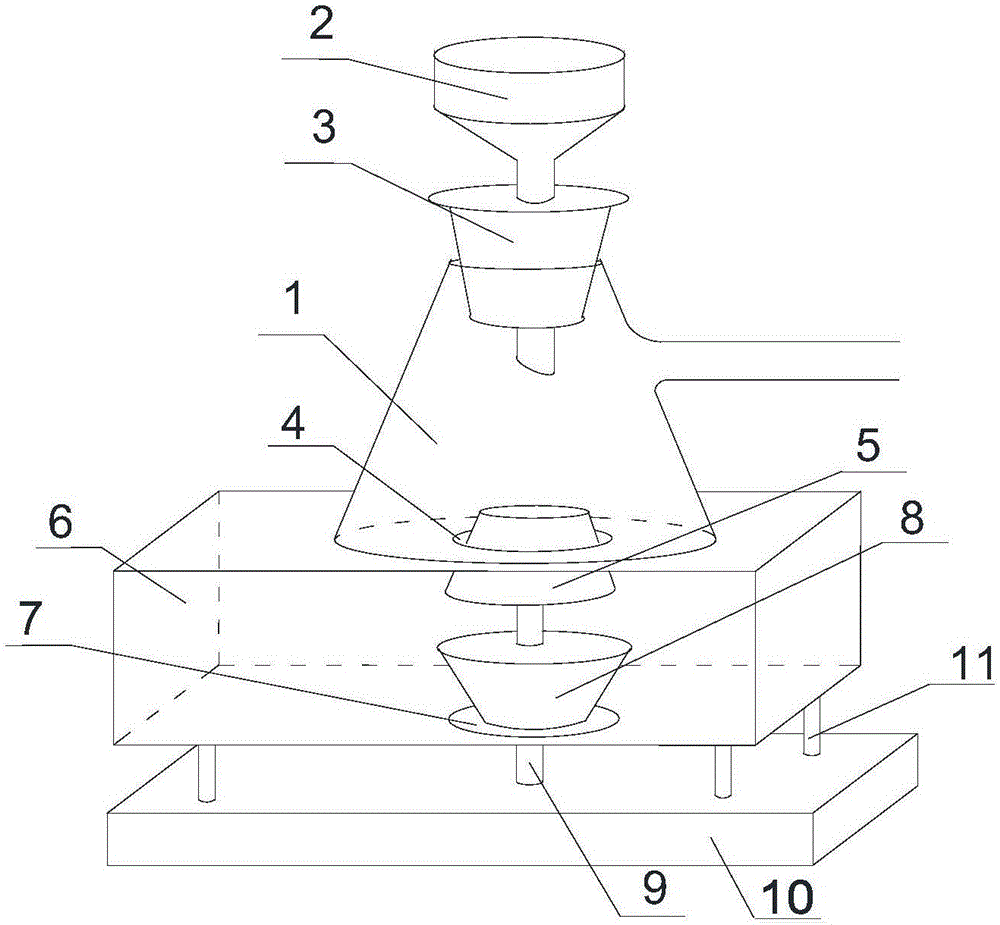

[0022] Such as figure 1 As shown, a kind of suction filtration bottle of the present invention has the vacuum filtration equipment of draining function, comprises suction filtration bottle 1, the suction filtration funnel 2 that cooperates suction filtration with suction filtration bottle 1, the connection between suction filtration funnel 2 and suction filtration bottle 1 The first cork 3 for inserting the lower end of the suction filter funnel 2 into the suction filter bottle 1 is arranged between, and the bottom of the suction filter bottle 1 is provided with a drain tank 6 with a top cover, and the suction filter bottle 1 is placed on the top cover of the drain tank 6 Above, the bottom of the suction filter bottle 1 is provided with a through hole 4 communicating with the inside of the drain tank 6, and the inside of the drain tank 6 is provided with a second cork 5 for blocking the through hole 4, and the second cork 5 is connected below the second cork 5. The pull rod 9 ...

Embodiment 2

[0025] Based on embodiment 1, the bottom of the drainage groove 6 is provided with a drainage hole 7, and the drainage hole 7 is concentric and coaxial with the through hole 4, and the inside of the drainage groove 6 is provided with a third cork 8 for blocking the drainage hole 7, and the third cork The stopper 8 is positioned at the bottom of the second cork 5, and the pull rod 9 passes through and fixes the third cork 8.

[0026] In the present invention, the third cork and the second cork are fixed on the same pull rod; when the suction filter bottle does not need to drain, the pull rod is pushed upwards, so that the second cork blocks the through hole of the suction filter bottle, and when necessary When draining, pull the pull rod downward, the through hole will be opened when the pull rod is downward, and the third cork will seal the drainage groove downward; after the liquid in the filter bottle is drained, push the pull rod upward, the second cork will re- Block the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com