Environment-friendly dust-cleaning apparatus for ceramic making

A technology of dust removal equipment and ceramics, which is applied in separation methods, transportation and packaging, separation of dispersed particles, etc., can solve problems such as affecting the health of production personnel, incompleteness, and unsatisfactory dust removal effect, achieving ideal cleaning effect and preventing damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The environment-friendly dedusting equipment for ceramic production of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

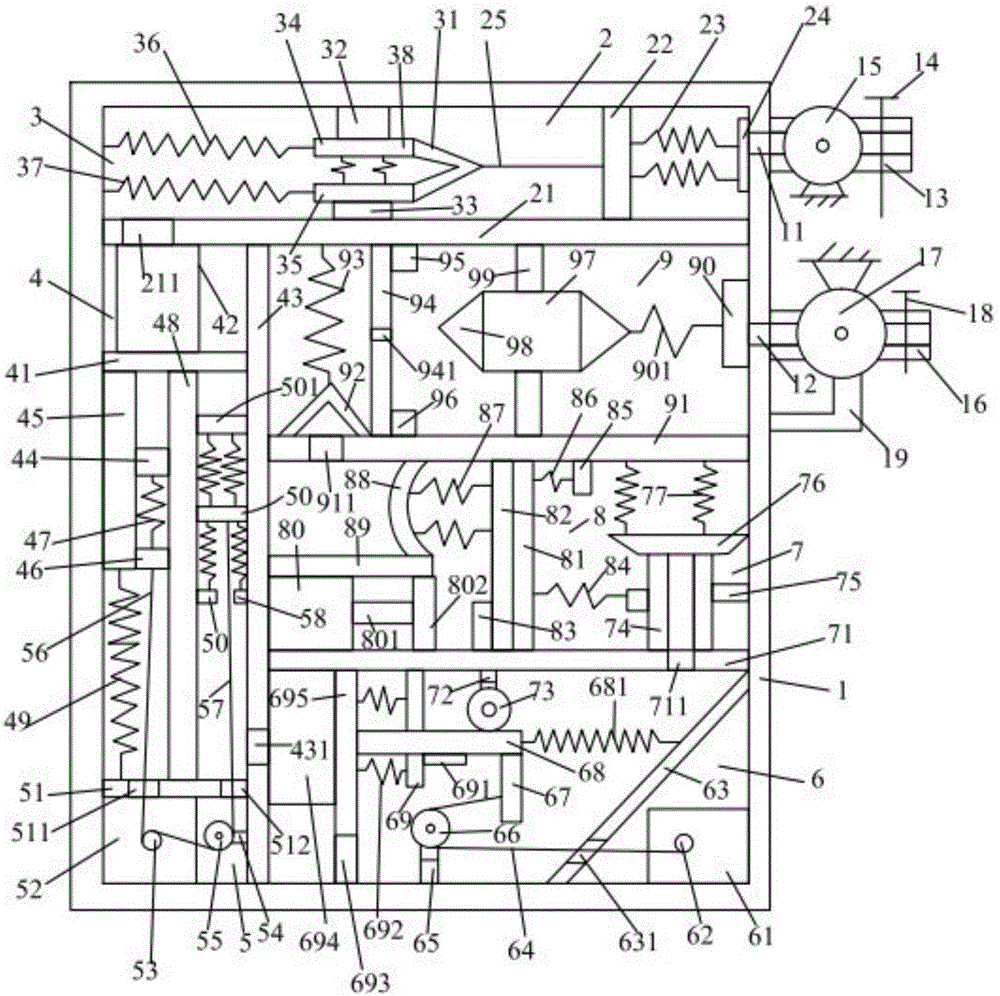

[0010] Such as figure 1 As shown, the environment-friendly dust removal equipment for ceramic production of the present invention includes a housing 1, a first filter device 2 accommodated in the housing 1, and a second filter device 3 arranged on the first filter device 2 , the third filter device 4 below the first filter device 2, the motor device 5, the fourth filter device 6 on the right side of the motor device 5, the stopper device 7 above the fourth filter device 6 , the fifth filter device 8 located on the left side of the block device 7 and the buffer device 9 located above the fifth filter device 8 .

[0011] Such as figure 1 As shown, the housing 1 is a hollow cuboid and placed vertically. The housing 1 is provided with a first through hole 11 on its right surface, a seco...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap