Electric washing water gun

A water gun and electric technology, applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as the inability to adjust the direction and angle of the water gun well, and meet the requirements of flushing operations and easy operation , design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

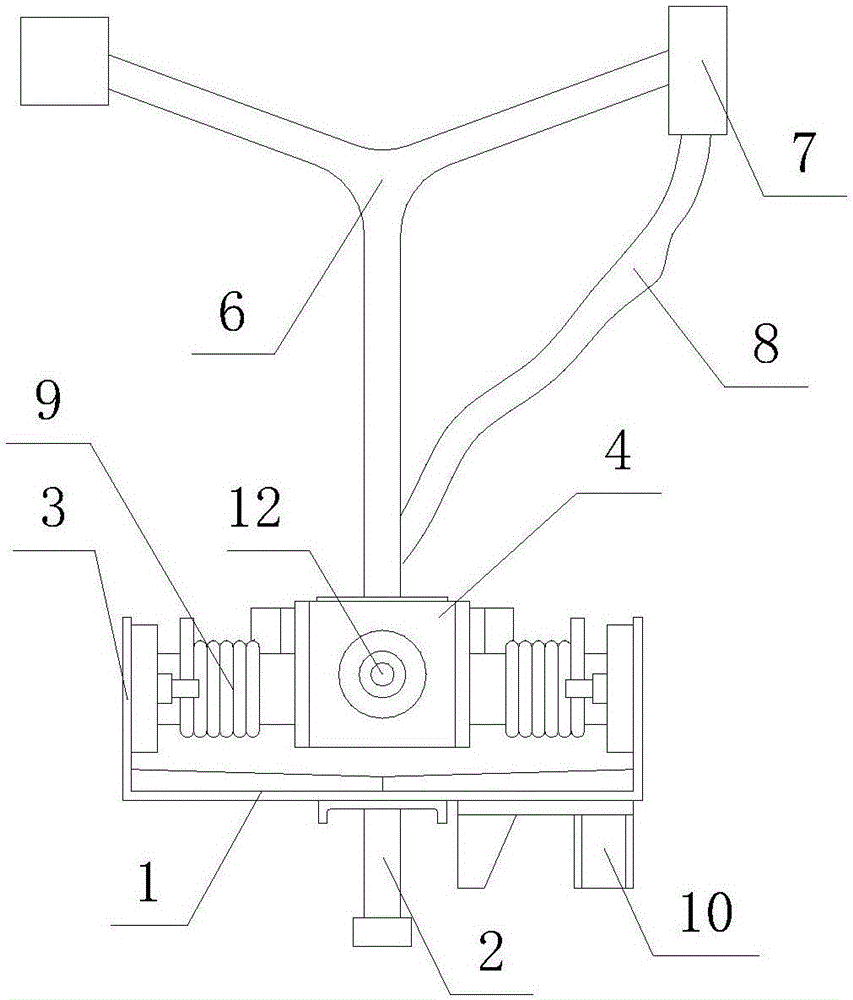

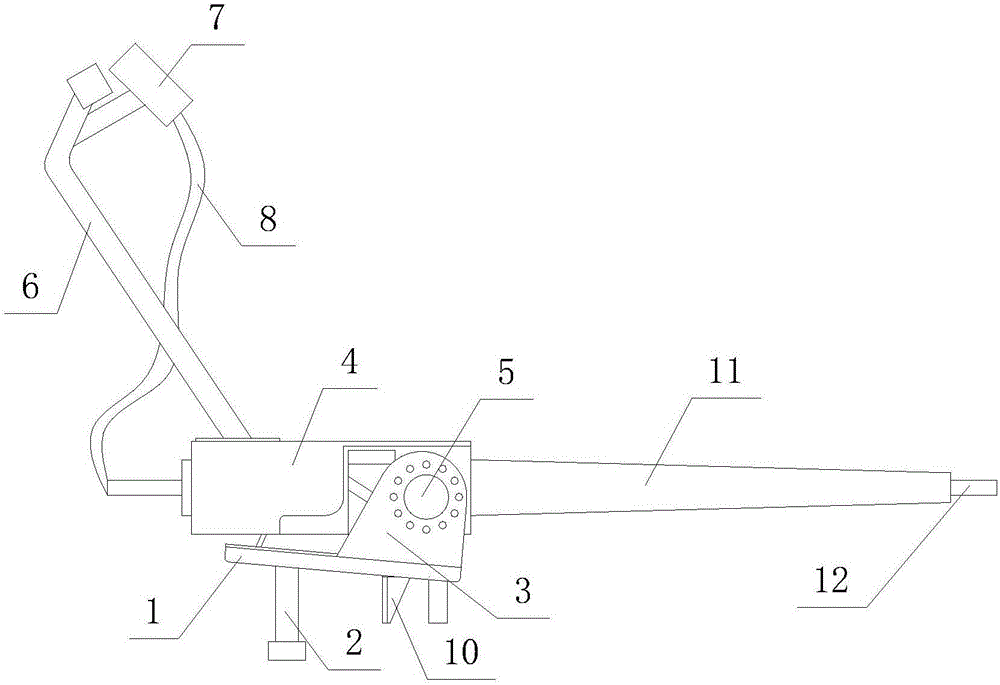

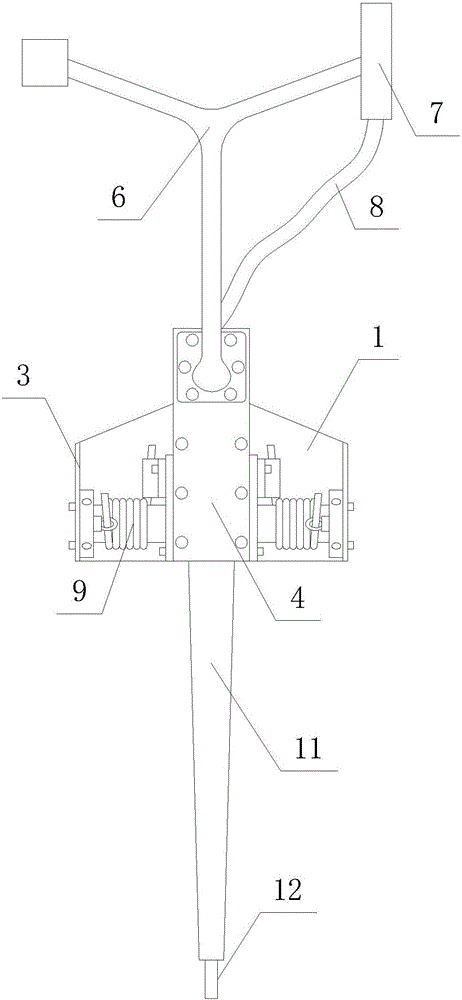

[0016] Such as Figure 1 to Figure 3 As shown, an electric flushing water gun includes a base plate 1, a vertical shaft 2 is pivotally connected to the lower surface of the base plate 1, and a side plate 3 is respectively provided on both sides of the upper surface of the base plate 1, and the side plate 3 and the base plate 1 is made in one piece. A horizontal shaft 5 is connected between the two side plates 3 by ball bearings, the horizontal shaft 5 is provided with a water gun holder 4, and the horizontal shaft 5 is inserted into the inside of the water gun holder 4, so that the water gun holder 4 can be horizontally Shaft 5 rotates as the axis. The front end of the water gun holder 4 is connected with a water gun 11 . The top of described water gun holder 4 is provided with operating handle 6, and this operating handle 6 is provided with water gun trigger 7, and on the water gun trigger 7, connects an end that connects water pipe 8, connects the other end of water pipe 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com